Pressing-drawing-type chain pulley transmission variable speed gear and pedal type step bicycle

A technology of pressing and zipping chains and shifting devices, which is applied in the directions of bicycles, motor vehicles, and vehicle parts, can solve the problems of high manufacturing cost, poor reliability, complicated structure, etc., and achieve the effect of increasing lung capacity and enhancing coordination ability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

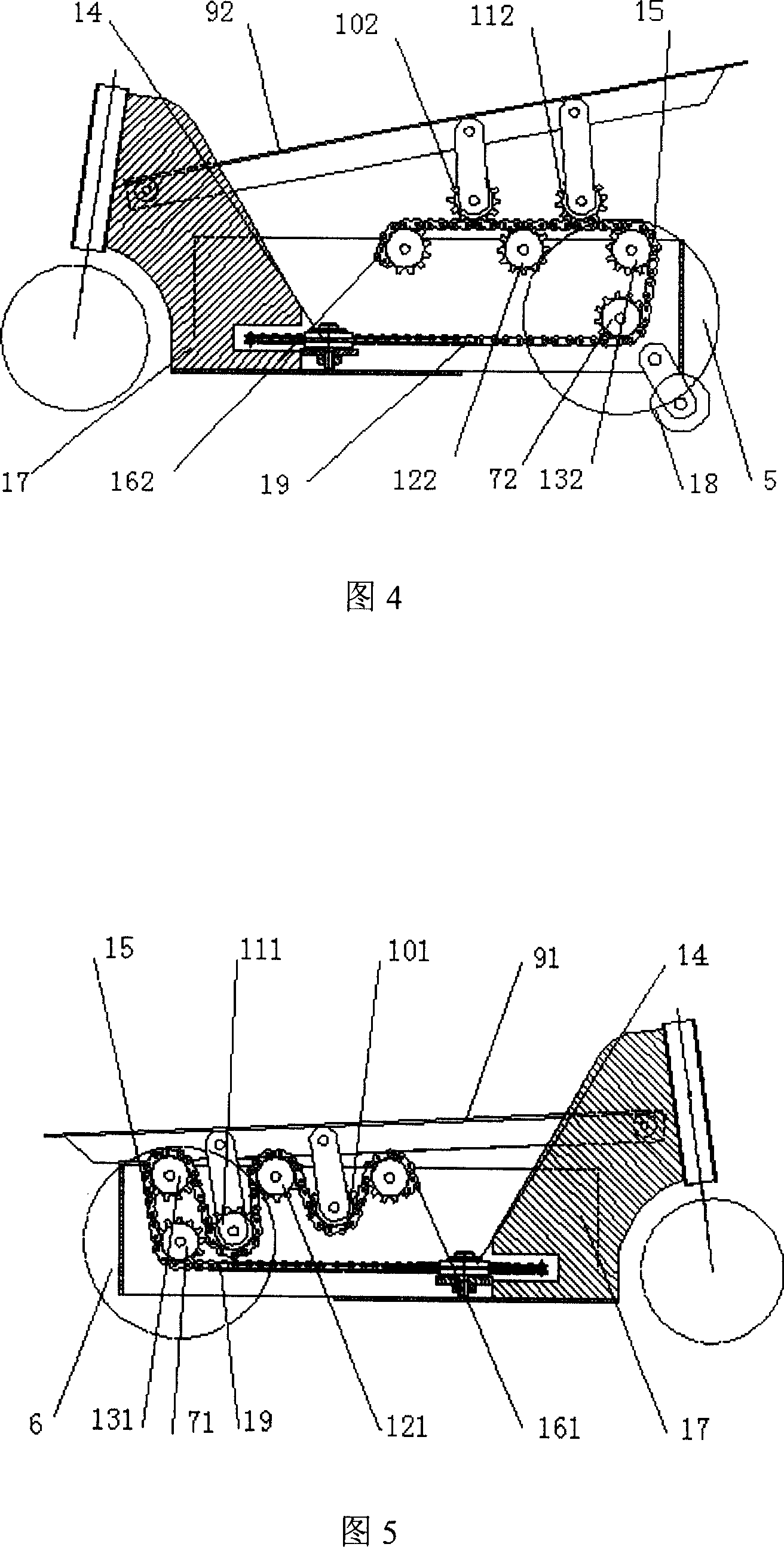

[0030] As shown in Figures 4 and 5, a compression-pull chain pulley transmission speed change device includes two sets of symmetrically arranged chain pulley speed change assemblies, a vertical sprocket 14, a speed change assembly with the two sets of chain pulleys and the The chain 15 matched with the vertical sprocket 14 is connected with a chain cross joint 19, 19 (left and right sides) between the vertical sprocket 14 and each group of chain pulley shift components.

[0031] Two sets of symmetrically arranged chain pulley shift components: one set is two left driving chain pulleys 101, 111, two left driven chain pulleys 121, 131 arranged alternately with the two left driving chain pulleys 101, 111, and one fixed The sprocket 161 (which is fixed and non-rotating, the left end of the chain 15 is fixed on the fixed sprocket 161) and a left one-way ratchet flywheel 71; the other group is two right drive chain pulleys 102, 112, three Two right driven chain pulleys 122, 132 arranged...

Embodiment 2

[0036] The difference between the second embodiment and the first embodiment is that each chain pulley is replaced by a steel rope pulley, and the one-way ratchet flywheel is replaced by a steel rope flywheel, which is connected by a steel rope, which can achieve less driving force requirements The compression pull type steel rope pulley shifts, in addition, the above-mentioned chain cross joint 19 is also omitted.

[0037] The positions and connection relations of the components of the second embodiment and the first embodiment are the same, and will not be repeated here.

Embodiment 3

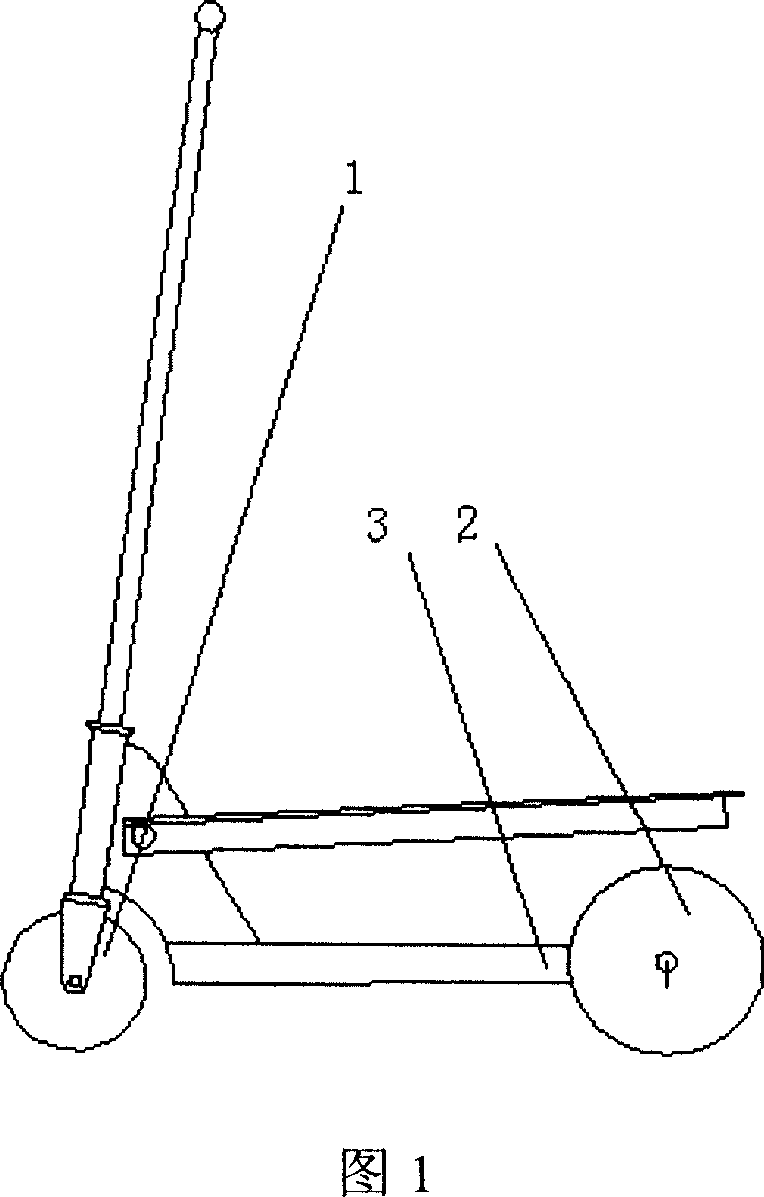

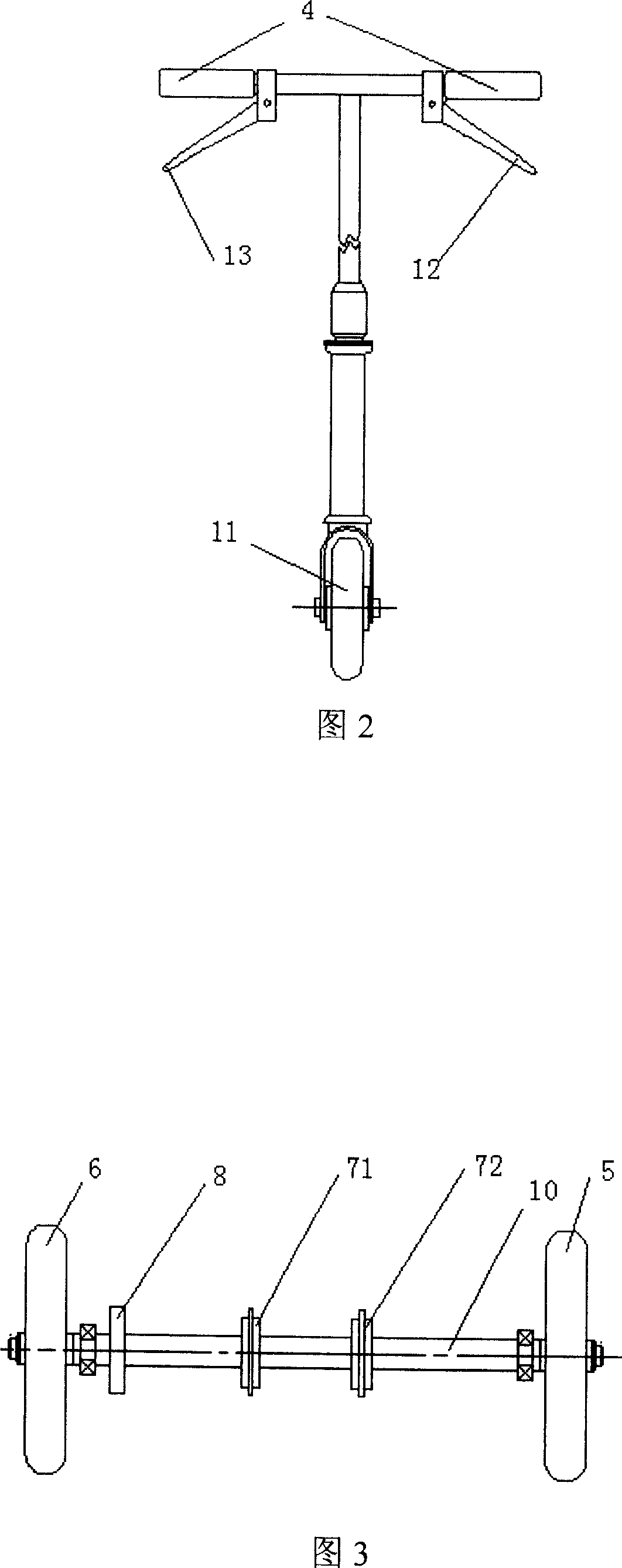

[0039] As shown in Figure 1 to Figure 7, a pedal-type stepping bicycle is a kind of pedaling with two pendulum pedals alternately, pressing and pulling the chain and accelerating the rotation of the one-way ratchet flywheel to make the wheel move forward continuously. It accelerates while driving, and realizes a differential device in which one pedal goes down and the other pedal automatically goes up.

[0040] The pedal-type stepping bicycle includes a front wheel part 1, a rear wheel part 2, and a frame part 3 connected between the front wheel part 1 and the rear wheel part 2. The frame part 3 includes a correspondingly set up and down swing The left and right pedals 91, 92 and the pressure-pull sprocket gear transmission device connected with the left and right pedals 91, 92, the rear wheel component 2 includes a differential coaxially correspondingly arranged driving rear wheel 5, a differential The driving rear wheel 6 and a reversing small wheel 18 installed inside the drivi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com