One key operation program controlling method for washing machine

A washing machine and program technology, which is applied to the control device, washing device, textile and paper making of washing machine, etc., can solve the problems of complicated and trivial operation and insufficient user convenience, and achieve the effect of improving the convenience of use and reducing the difficulty of operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

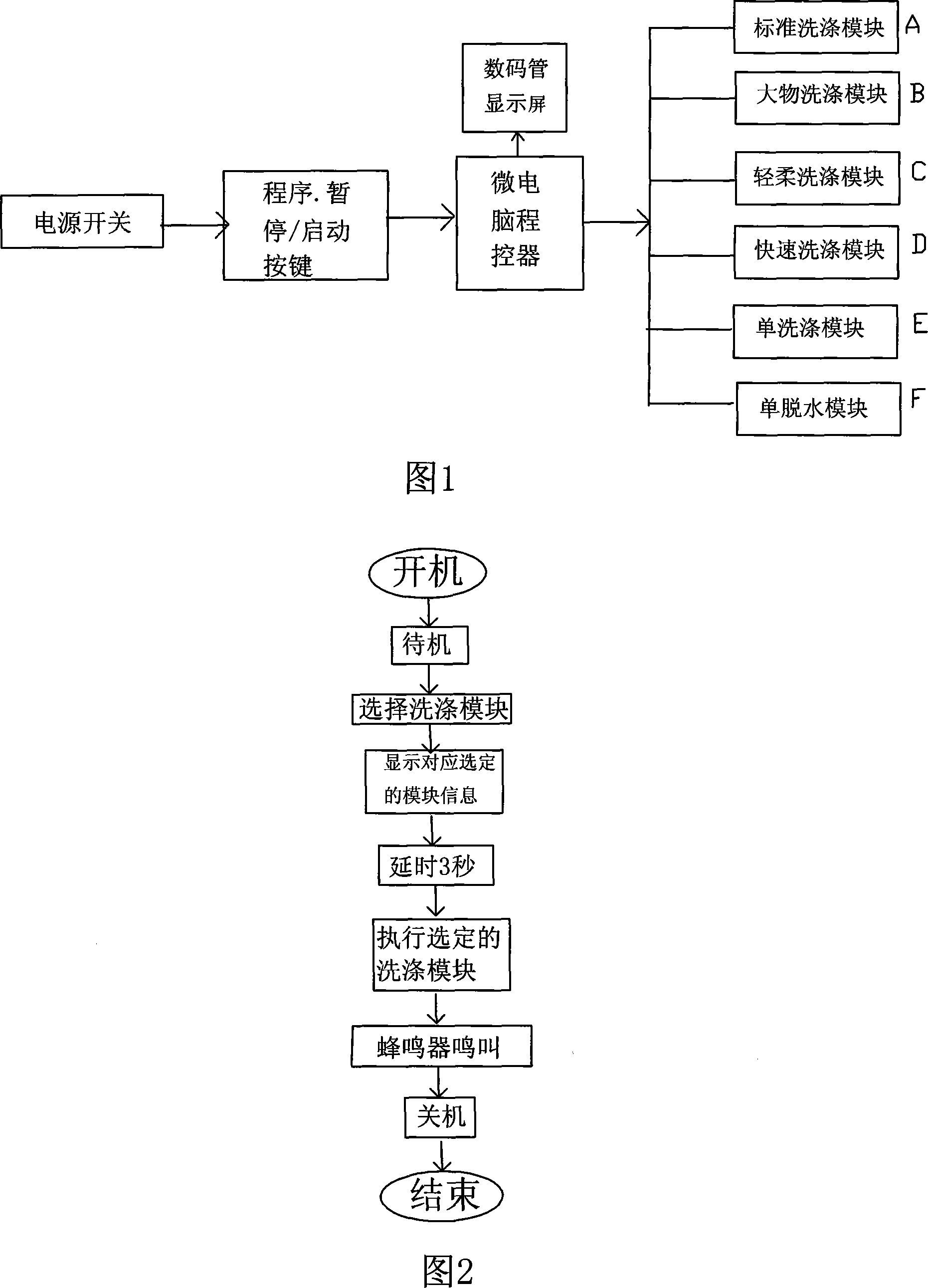

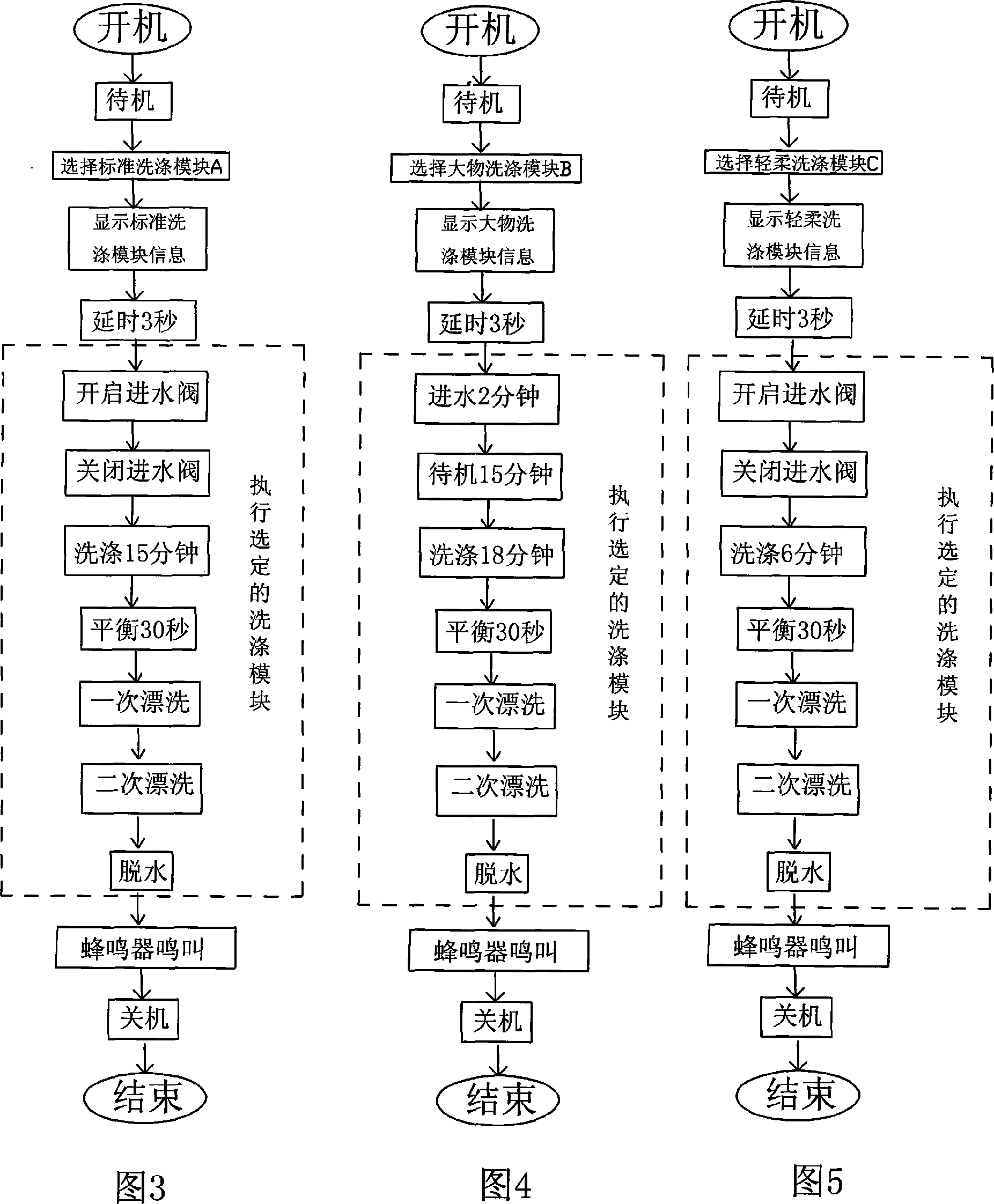

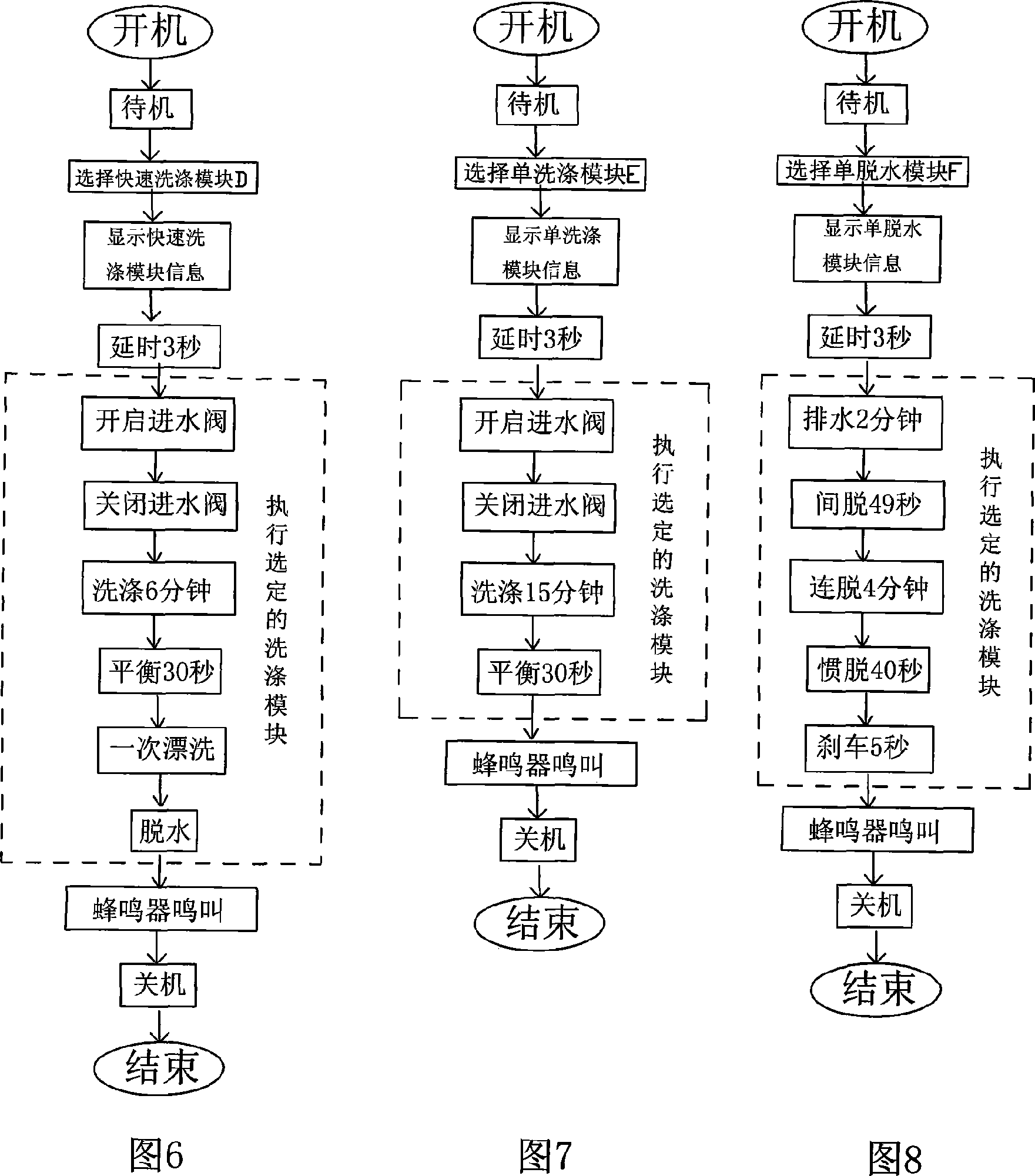

[0024] As shown in Fig. 1 and Fig. 2, the push-to-talk program control method of the washing machine disclosed by the present invention includes a microcomputer program controller, which is connected with a program / pause / start button integrated with program, pause and start function keys through the data channel; The key function of this program contains any selected six washing modules, which are composed of standard washing module A, large object washing module B, gentle washing module C, fast washing module D, single washing module E, and single dehydration module F; After the microcomputer program controller receives the start-up signal sent by the power switch, it controls the digital tube display to display the standby information "00"; and continuously presses its program·pause / start button according to the information of the light touch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com