Valve hydraulic driver

A hydraulic driver and driver technology, applied to valve details, valve devices, engine components, etc., can solve problems such as slow response speed, difficult motor performance, and influence on opening performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

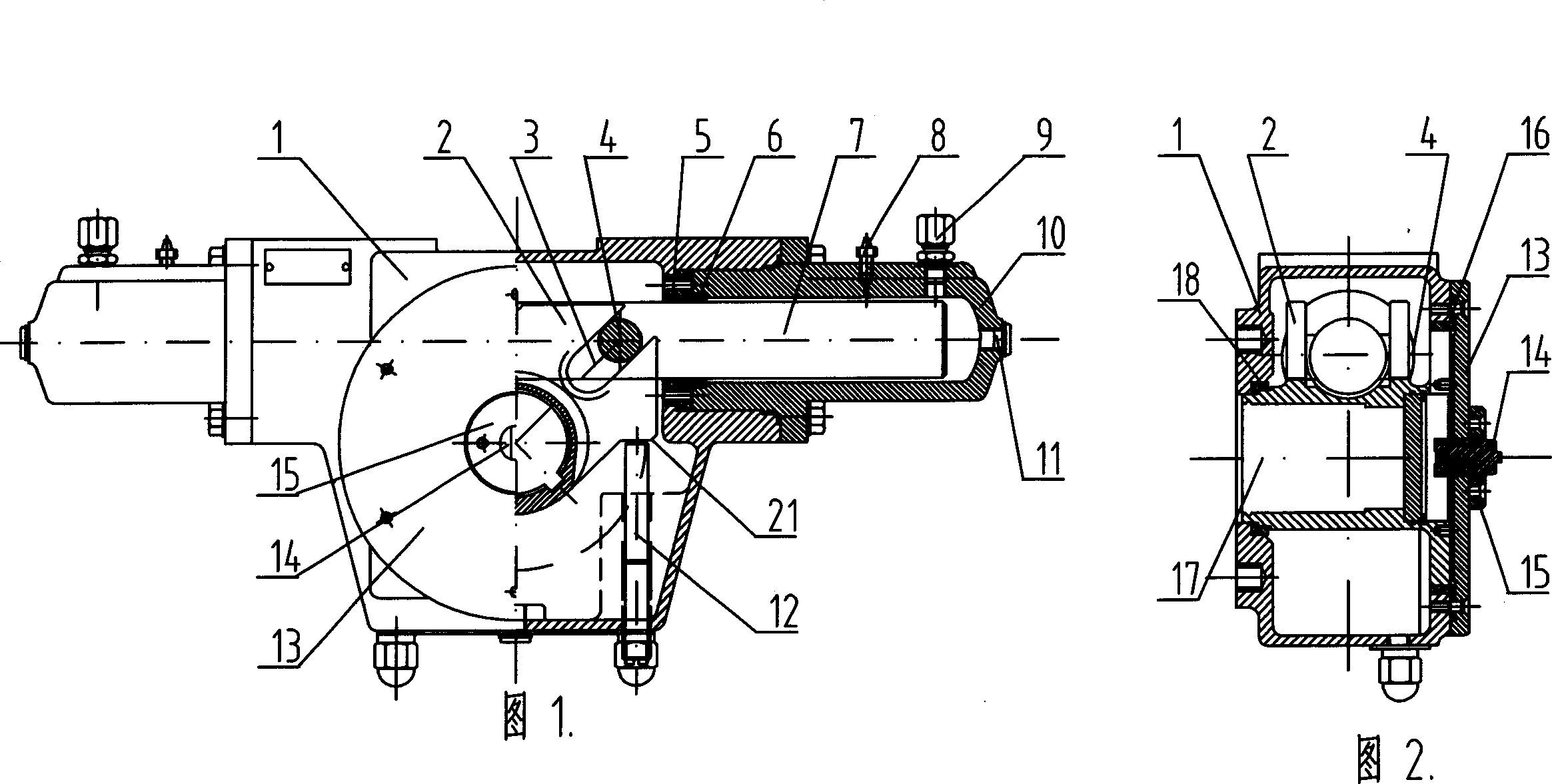

[0018] In the valve hydraulic actuator shown in FIG. 1 and FIG. 2 , the power source hydraulic cylinder includes a hydraulic cylinder barrel 10 and a piston rod 7 slidably placed in the hydraulic cylinder barrel 10 . Two hydraulic cylinder barrels 10 are symmetrically installed on the driver housing 1 , and the two opposite hydraulic cylinder barrels 10 are respectively sleeved on two ends of the piston rod 7 , and the piston rod 7 can slide left and right in the hydraulic cylinder barrel 10 . Each hydraulic cylinder 10 seals the piston rod 7 on the hydraulic cylinder 10 through the sealing ring 6 and the cylinder end cover 5 , so that the piston rod 7 is slidably supported on the driver housing 1 through the hydraulic cylinder 10 . Each hydraulic cylinder 10 is respectively equipped with an air release bolt 8 and a straight-through pipe joint 9, and the straight-through pipe joint 9 is directly connected with a pressure source or a manual pump in manual operation or in an emer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com