Drilling well headframe plane rocking test set

A new device, a flat technology, applied in measuring devices, using optical devices to transmit sensing components, force/torque/work measuring instruments, etc., can solve the problems of complex mathematical calculations, and it is difficult to effectively reflect the overall swing of the derrick, etc. Achieve the effect of preventing construction accidents and derrick accidents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

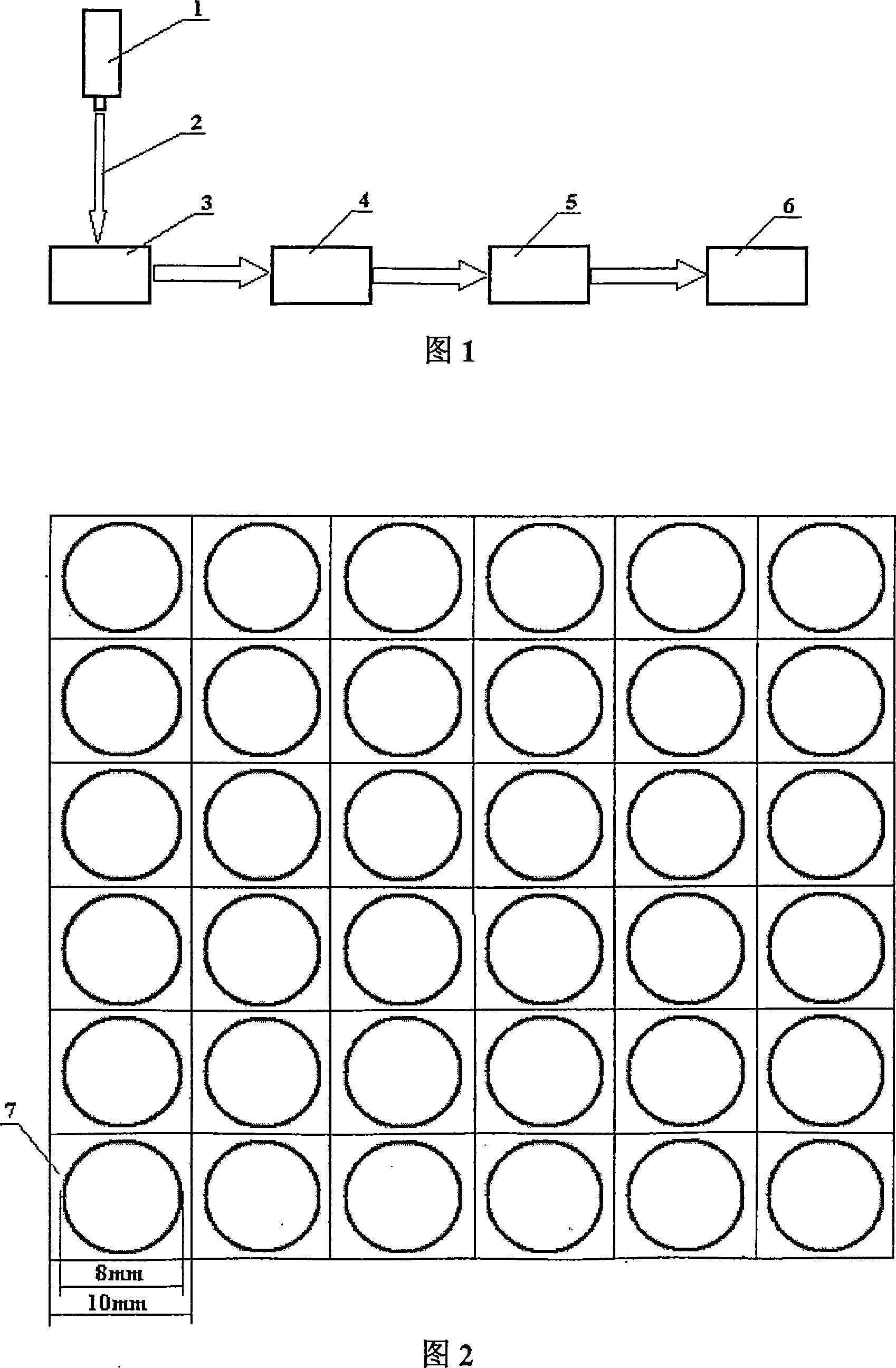

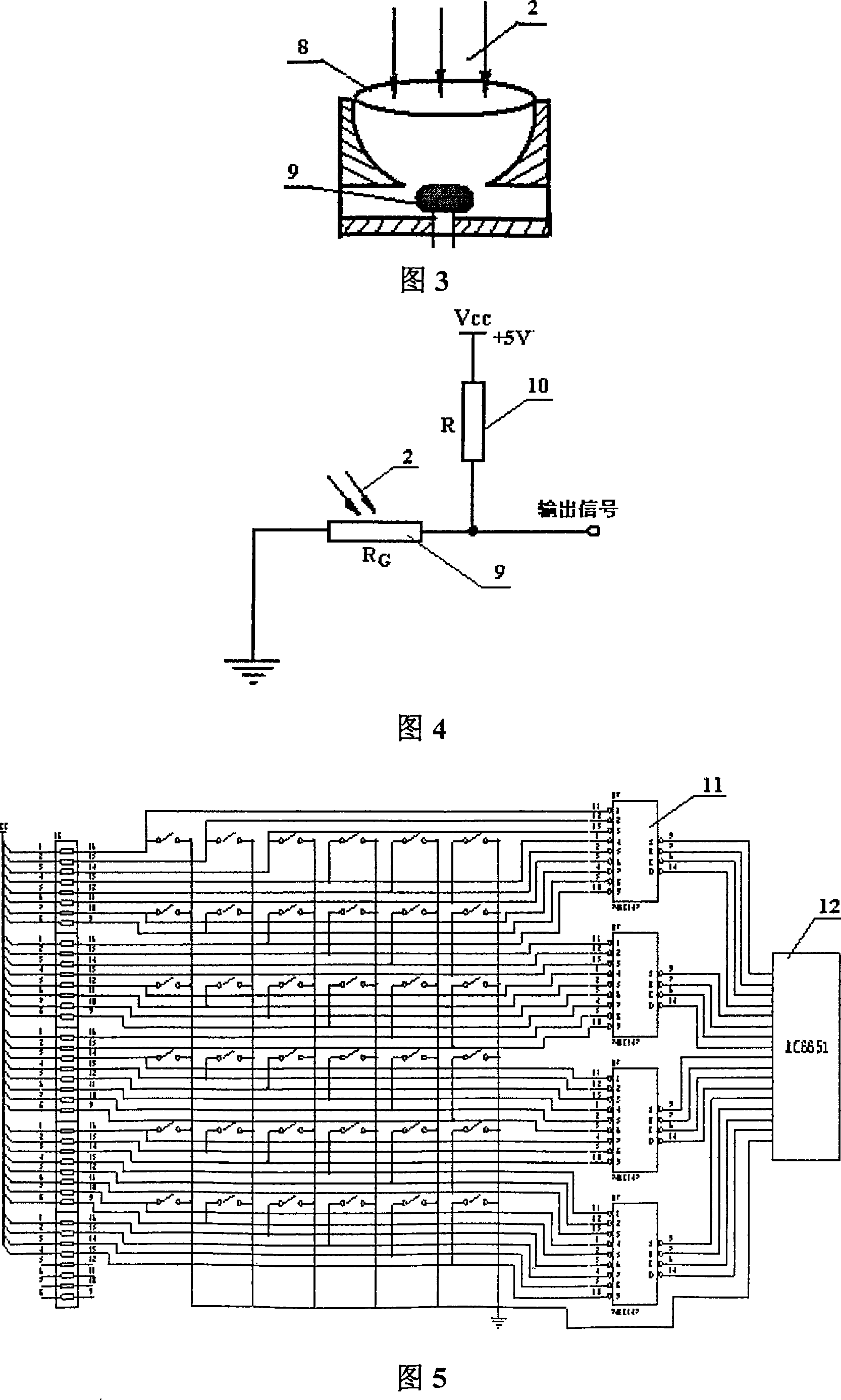

[0012] Install the laser 1 on the top of the drilling derrick. When the laser 1 swings with the sway of the derrick, the laser beam 2 is irradiated vertically downward to the plane photoelectric sensor array 3 placed horizontally on the ground, and the laser beam 2 is focused on the photoelectric sensor array through the concave mirror 8. on the photoresistor 9 in the When the photoresistor 9 is under normal light (no laser beam irradiation), its resistance value is about 3kΩ; when there is laser beam irradiation, its resistance value is about 0.3kΩ; About 3kΩ), under normal light, the output signal is about 2.5V, which can be regarded as high level. When there is laser beam irradiation, the output signal is about 0.5V, which can be regarded as low level, which meets the input level requirements of the data acquisition card. The output signal of the 36-channel photoelectric sensor array after photoelectric signal conversion is sent to four 10-4-wire encoders 11 for encoding. A...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| power | aaaaa | aaaaa |

| electrical resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com