Motor with brush

A technology of motors and brushes, applied in the direction of brush manufacturing, current collectors, casings/covers/supports, etc., can solve problems such as inability to cope, and achieve the effects of prolonging life, suppressing wear, and improving vibration attenuation characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] Embodiments of the present invention will be described below with reference to the drawings.

[0039] (The overall structure of the brushed motor)

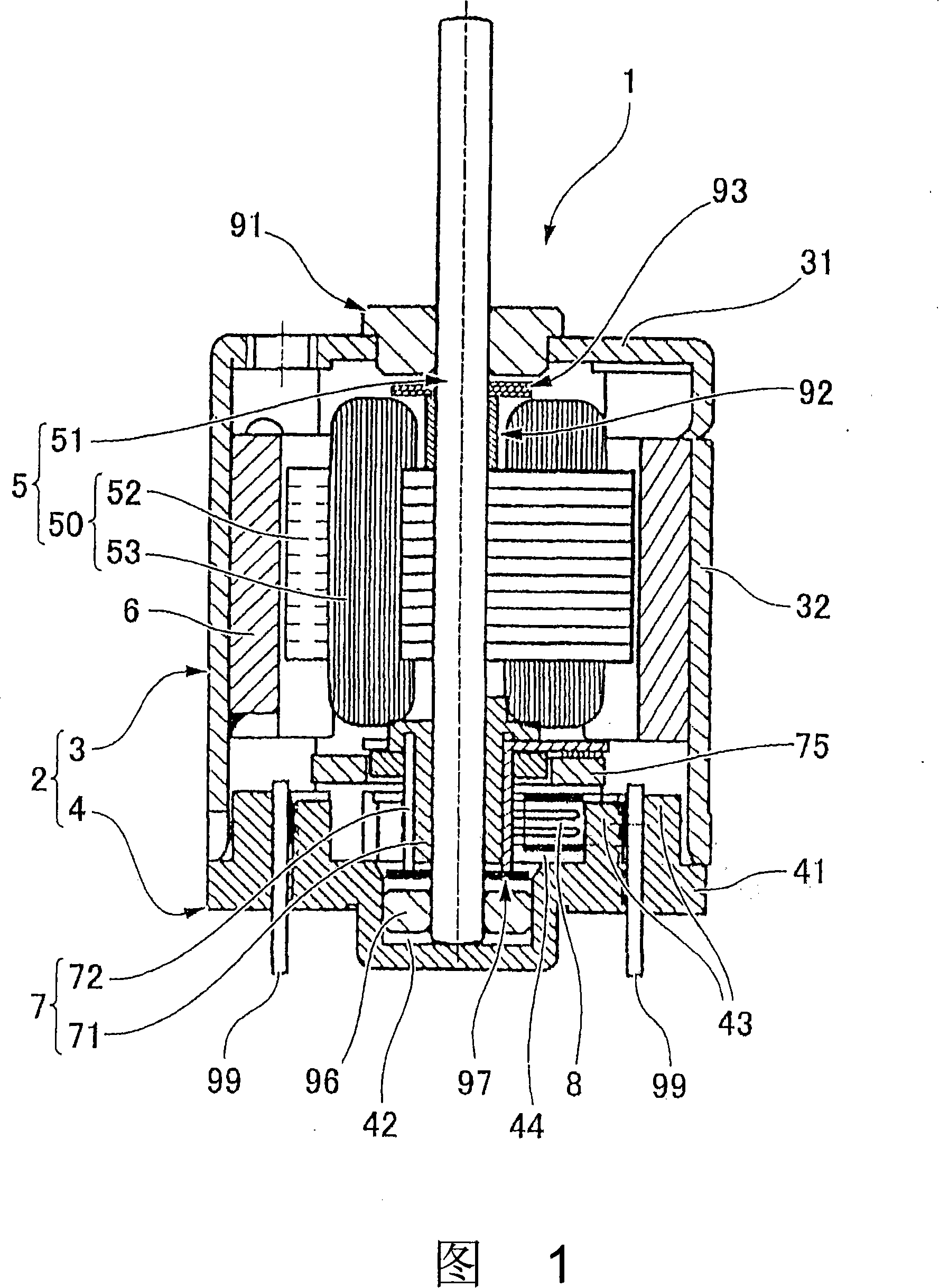

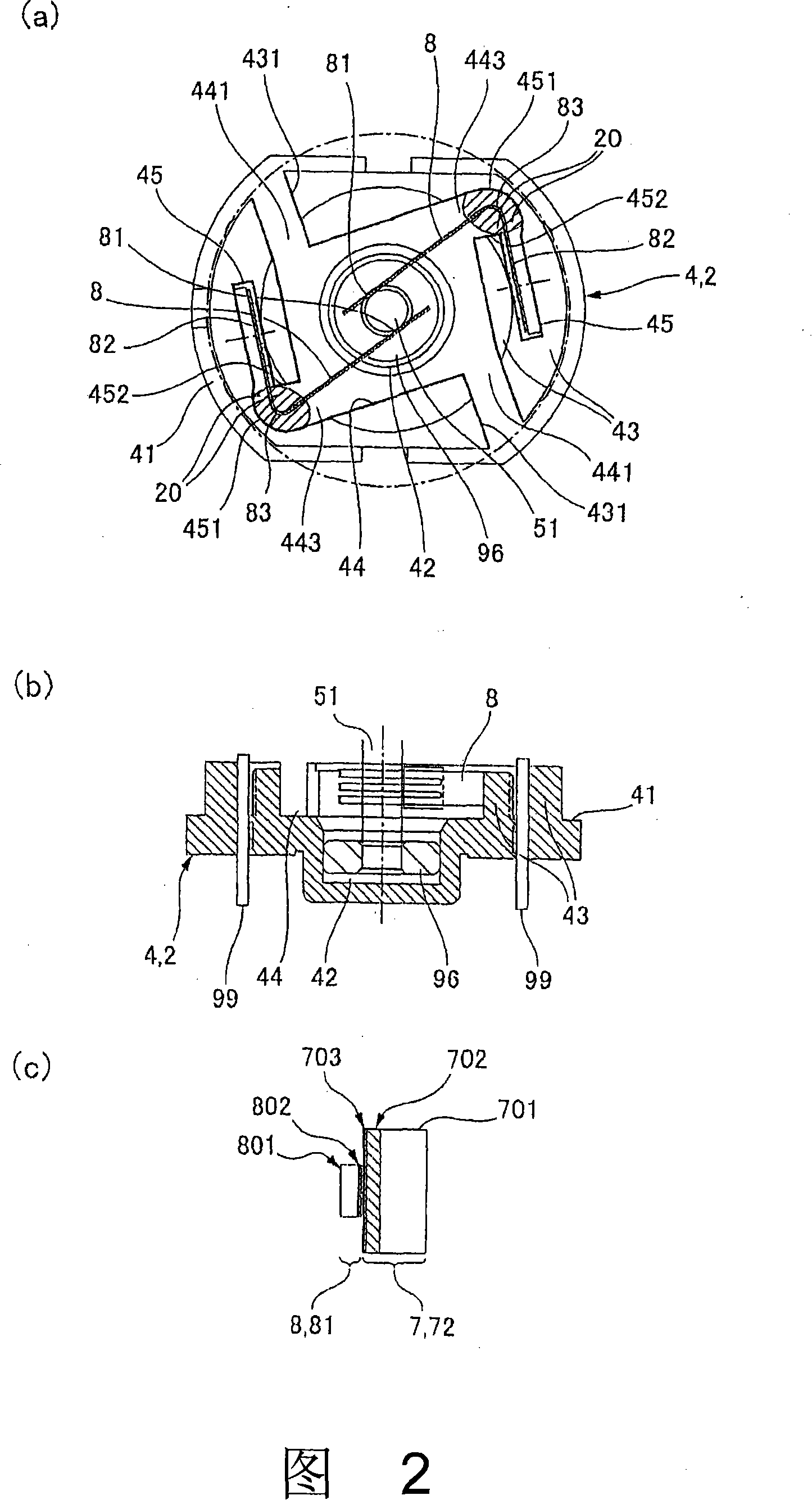

[0040] FIG. 1 is a cross-sectional view showing the overall structure of a brushed motor to which the present invention is applied. Fig. 2(a) is a top view showing the brush and the brush holder pulled out from the brushed motor shown in Fig. 1, Fig. 2(b) is a cross-sectional view thereof, and Fig. 2(c) is a view of the brush and the commutator Explanatory diagram of the sliding part.

[0041] In FIG. 1 , the brushed motor 1 of this embodiment is a small DC motor with a brush, and the output end side of the rotating shaft 51 protrudes from the upper end surface 31 of the cup-shaped motor case 3 . Inside the motor housing 3 , an iron core 52 made of laminated magnetic plates is fixed to an approximately central portion in the axial direction of the rotating shaft 51 by press-fitting or the like. A plurality of salient pol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com