Steel thin wall penetration pipe and its fitting parts

A technology for threading pipes and thin walls, applied in electrical components and other directions, can solve the problems of inconvenient construction, inability to operate in two directions, and high production costs, and achieve the effects of convenient on-site construction, good sealing performance, and beautiful appearance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

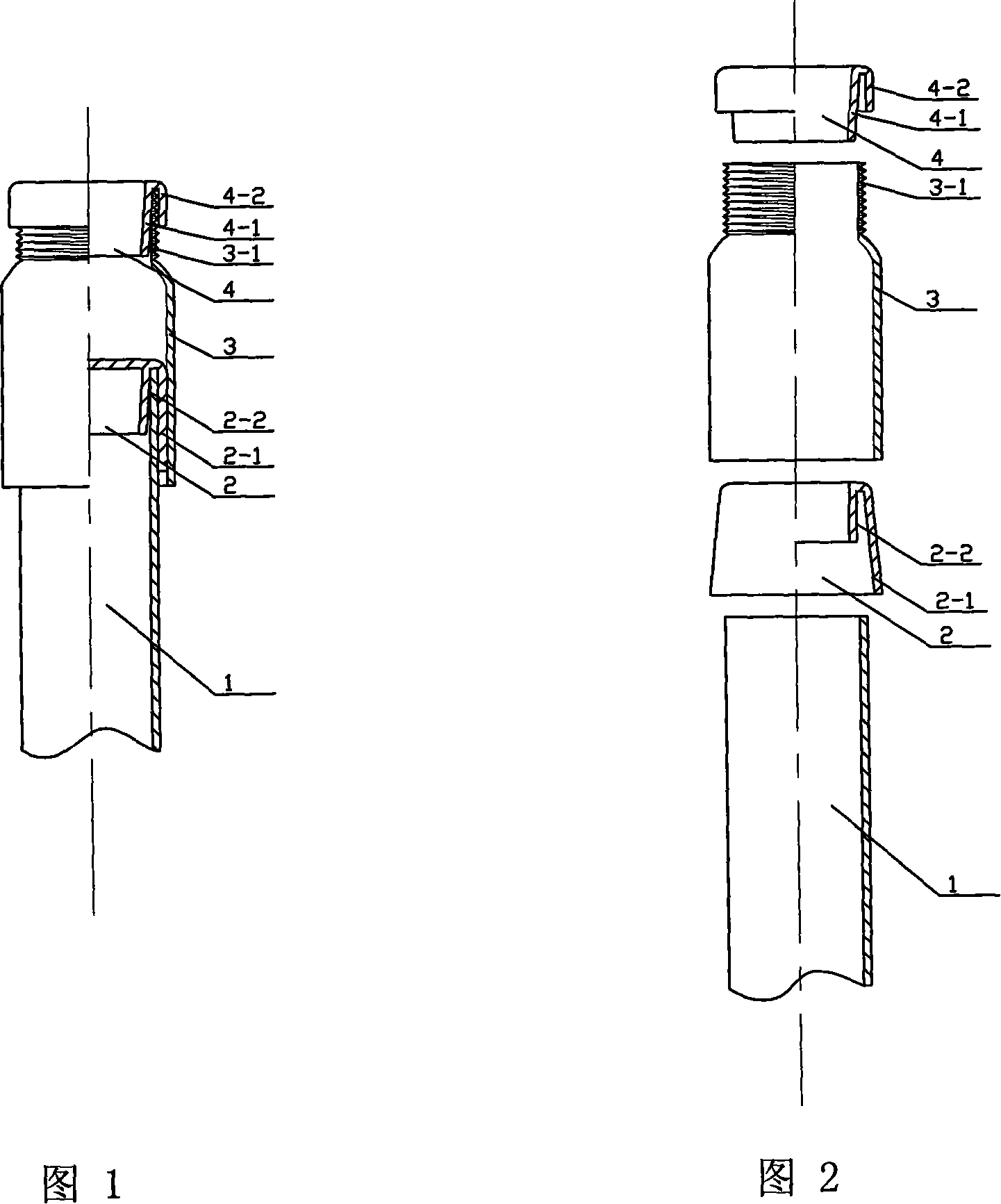

[0015] Referring to Fig. 1 and Fig. 2, a single-section stainless steel thin-wall threading pipe and its accessories consist of a thin-wall stainless steel threading pipe 1, a first embedded soft plastic sheath 2, a thin-wall stainless steel union 3, and a second embedded Connected soft plastic sheath 4 components. The wall thickness of the stainless steel threading pipe in this embodiment is 0.3 mm, and the wall thickness of the stainless steel joint is 0.7 mm. The first embedded soft plastic sheath 2 is composed of an outer sleeve 2-1 and an inner sleeve 2-2, the inner and outer sleeves are connected to the end together, and the width of the connection is equal to the thickness of the stainless steel pipe wall, preferably The outer sleeve 2-1 is longer than the inner sleeve 2-2, and both of them are slightly inclined outwards, so that the connection between the threading pipe 1 and the union 3 can be sealed better. The structural shape of the 2nd embedded type soft plastic ...

Embodiment 2

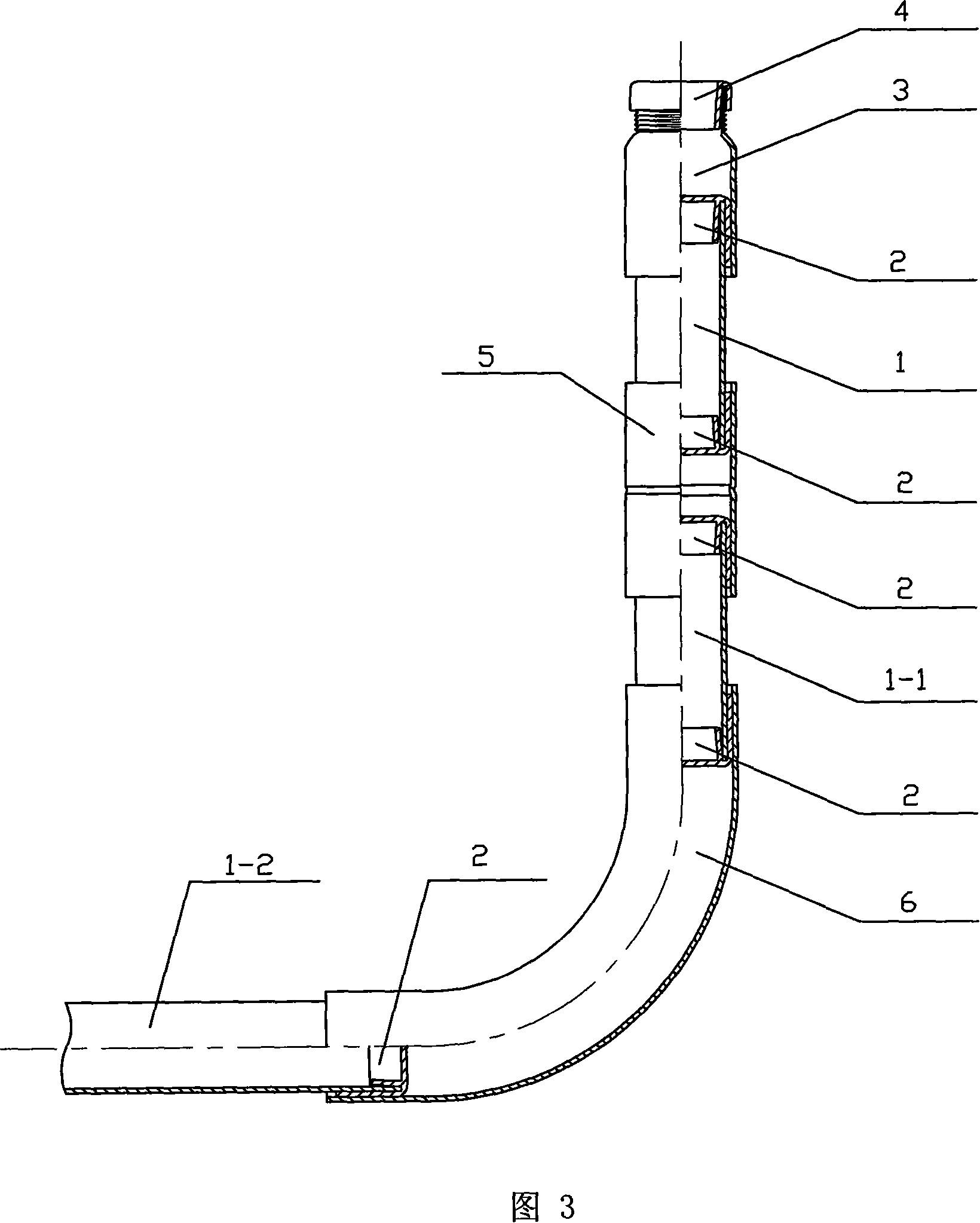

[0018] Referring to Figure 3, a multi-section stainless steel thin-walled threading pipe and joint connection structure is as follows: the front port of the stainless steel thin-walled threading pipe 1-2 passes through the first embedded soft plastic sheath 2 and the stainless steel thin-walled elbow 6 The rear part of the stainless steel thin-walled elbow 6 is sealed and connected to the rear port of the stainless steel thin-walled threading pipe 1-1 through the first embedded soft plastic sheath 2; the front port of the stainless steel thin-walled threading pipe 1-1 The rear part of the stainless steel thin-wall direct head 5 is sealed and connected through the first embedded soft plastic sheath 2; the front part of the stainless steel thin-wall direct head 5 is connected to the stainless steel thin-wall threading pipe through the first embedded soft plastic sheath 2 1 rear port sealing connection; subsequently with the stainless steel thin-walled union 3 and junction box con...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com