Vibration static micro generator based on liquid medium and its array

A micro-generator and liquid medium technology, applied in the field of micro-energy, can solve the problems of low-frequency vibration response, easy damage of suspension beams, and low conversion efficiency, and achieve high integration, improved response ability, and improved stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] Below in conjunction with accompanying drawing, the technical scheme of the present invention is further described:

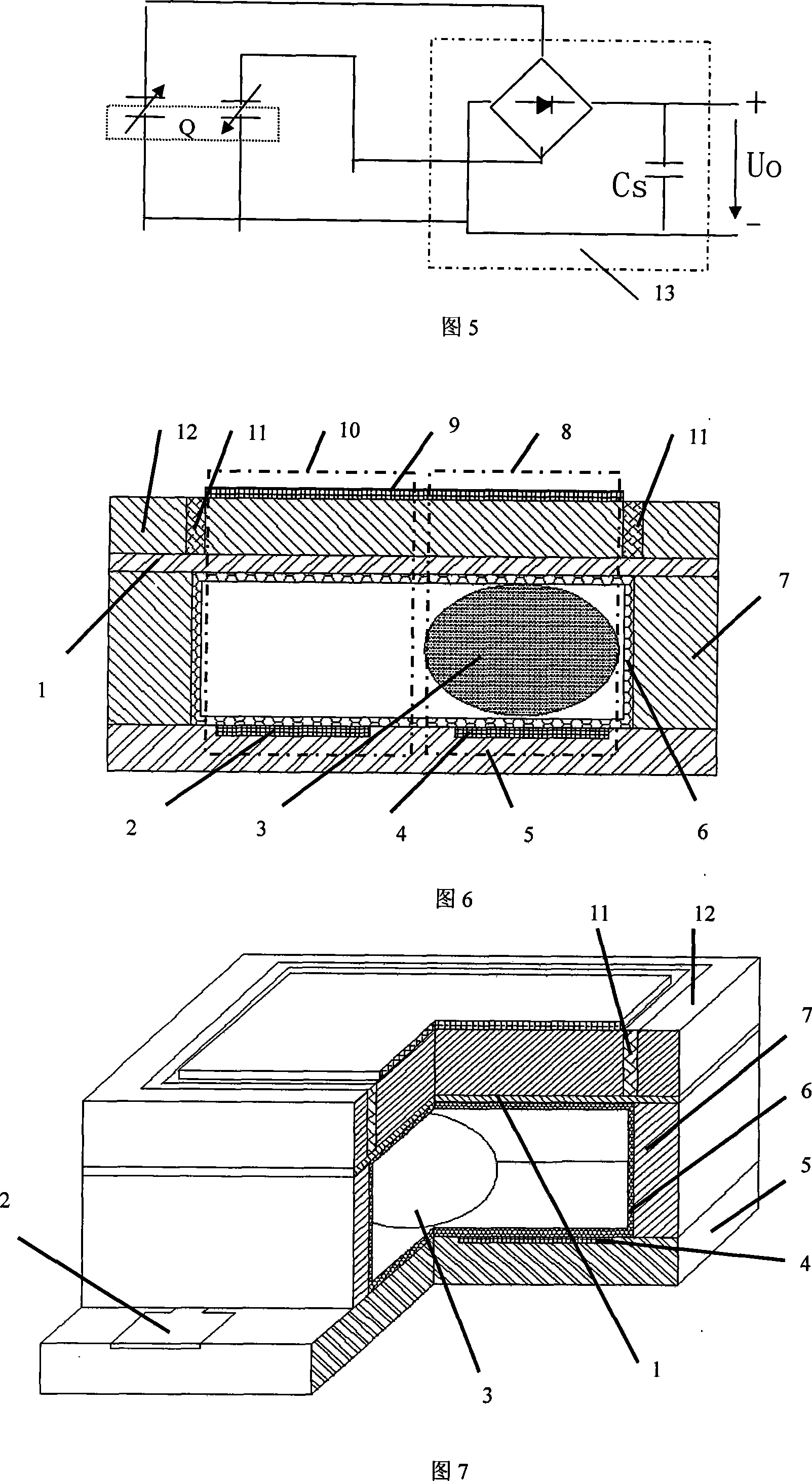

[0035] In conjunction with Fig. 6, Fig. 7 and Fig. 8, it can be seen that the vibrating electrostatic micro-generator based on the liquid medium mainly includes an electret 1, a first variable capacitor composed of a lower pole plate 2, a micro-liquid medium 3 and a common upper pole plate 9 10, the second variable capacitor and the processing circuit 13 formed by the lower plate 4, the micro-liquid medium 3 and the common upper plate 9, both variable capacitors are based on the substrate.

[0036] The substrate is divided into upper, middle and lower parts. In the middle of the middle substrate 7 is a cavity connected up and down formed by an etching process. The upper and lower parts cover the upper substrate 12 and the lower substrate through silicon-silicon bonding and silicon-glass bonding processes respectively. The bottom 5 forms a capacitor cavit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com