Method of manufacturing organic, inorganic compound fertilizer with molasses zymolysis waste liquor and lime sludge

A technology of fermentation waste liquid and compound fertilizer, which is applied in the preparation of organic fertilizers, organic fertilizers, and the treatment of biological organic parts, etc., can solve the problems of large space occupation, long fermentation cycle, poor biological activity of organic matter, etc., and reduce downtime for maintenance , the effect is obvious, the effect of saving energy

Inactive Publication Date: 2010-12-01

越百年创新肥业(海南)有限公司

View PDF5 Cites 1 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The disadvantage of this technology is that the filter mud is not fully fermented, the biological activity of the organic matter in it is poor, and the fertilizer efficiency of the fertilizer product needs to be improved.

The disadvantage of this technology is that the fermentation period is long, and a large number of turning operations occupy a large space; therefore, the production scale is limited, and the molasses fermentation waste liquid produced by large alcohol factories, large monosodium glutamate factories, and large yeast factories can only be partially digested; There will still be a large amount of molasses fermentation waste liquid that cannot be effectively treated

Until now, no processing technology has been widely accepted in the treatment of molasses fermentation waste liquid, and the recycling of waste liquid cannot be continuously operated in large quantities.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

Embodiment 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| Ash content | aaaaa | aaaaa |

Login to View More

Abstract

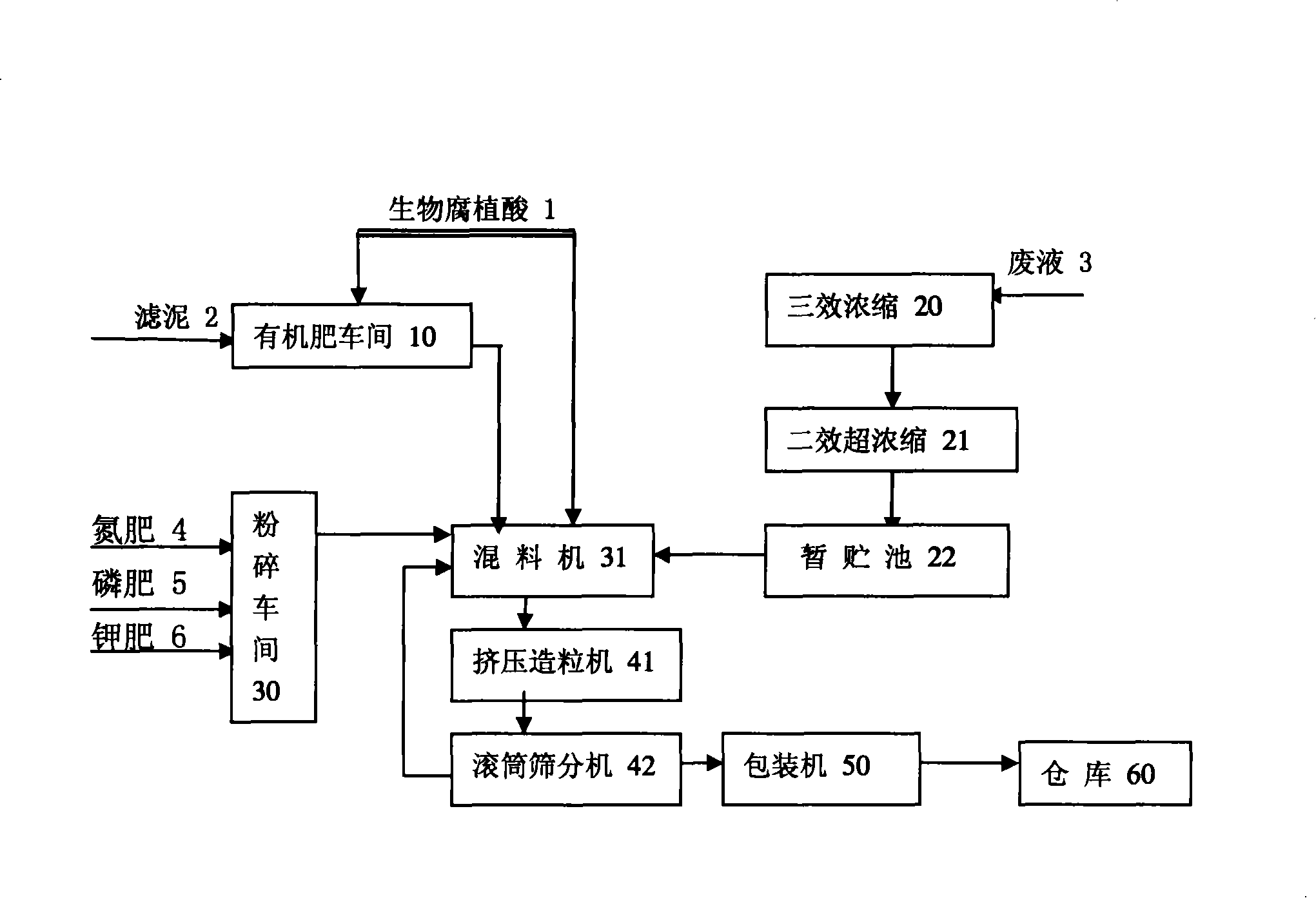

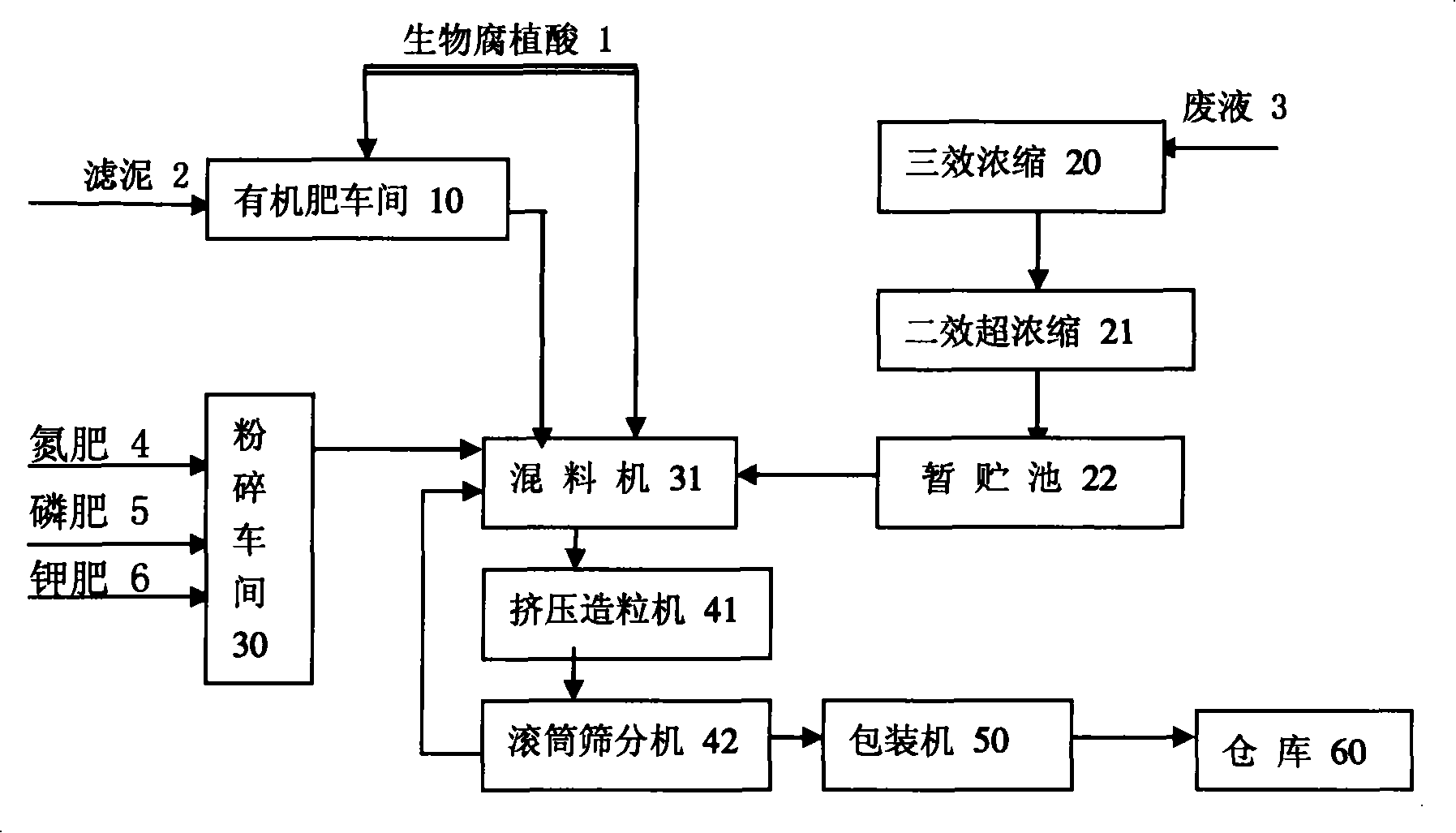

The invention provides a method producing the organic-inorganic compound fertilizer by the molasses fermentation waste liquor and the lime sludge, which relates to a method producing the fertilizer through fermentation and solves the problem of reclaiming and processing the molasses fermentation waste liquor continuously on a large scale. The method of the invention is that the biological humic acid with weight per cent of 0.4 per cent to 0.6 per cent and made by the bagasse is mixed with the lime sludge of 65 per cent to 68 per cent, bagasse powder of 10 per cent to 12 per cent, wheat bran of 1.5 per cent to 2.5 per cent and regulator of 16 per cent to 25 per cent to ferment fully and continuously in a shorter time. The fermented materials with water of 10 per cent to 12 per cent are gained after opening and drying and are crushed into the lime sludge organic fertilizer. The molasses fermentation waste liquor with water of 90 per cent is condensed to the hyperconcentration liquor with water of 26 per cent to 28 per cent by the three-effect forced circulating concentration system and then through the two-effect scraping and steaming hyperconcentration system. The hyperconcentration liquor of 30 per cent to 33 per cent and the biological humic acid of 9 per cent to 10 per cent are stirred and mixed uniformly based on the weight per cent and are added with the fertilizer of 32 per cent to 34 per cent and the lime sludge organic fertilizer of 25 per cent to 27 per cent to stir to produce the organic-inorganic compound fertilizer through dry extrusion and prilling.

Description

Method for producing organic-inorganic compound fertilizer with molasses fermentation waste liquid and filter mud technical field The invention relates to a method for producing fertilizer through fermentation, in particular to a method for producing fertilizer by using waste from sugar cane production and deep processing. Background technique During the sugar extraction process of the sugarcane sugar factory, a large amount of filter mud and molasses waste liquid are produced. Filter mud is rich in protein, nitrogen, phosphorus, potassium, calcium, magnesium, sulfur and other elements, as well as a large amount of organic matter. Because filter mud has a high water content and emits an unpleasant smell, people often discard it, or discharge it into rivers, or fill it in pits and ponds, which will cause serious environmental pollution over time. In order to facilitate the use of filter mud as organic fertilizer, people try to change the physical properties of filter mud....

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): C05G1/00C05F17/00C05F5/00C05F7/00C05F11/02

CPCY02A40/20Y02W30/40

Inventor 李瑞波蒲华明李建兴

Owner 越百年创新肥业(海南)有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com