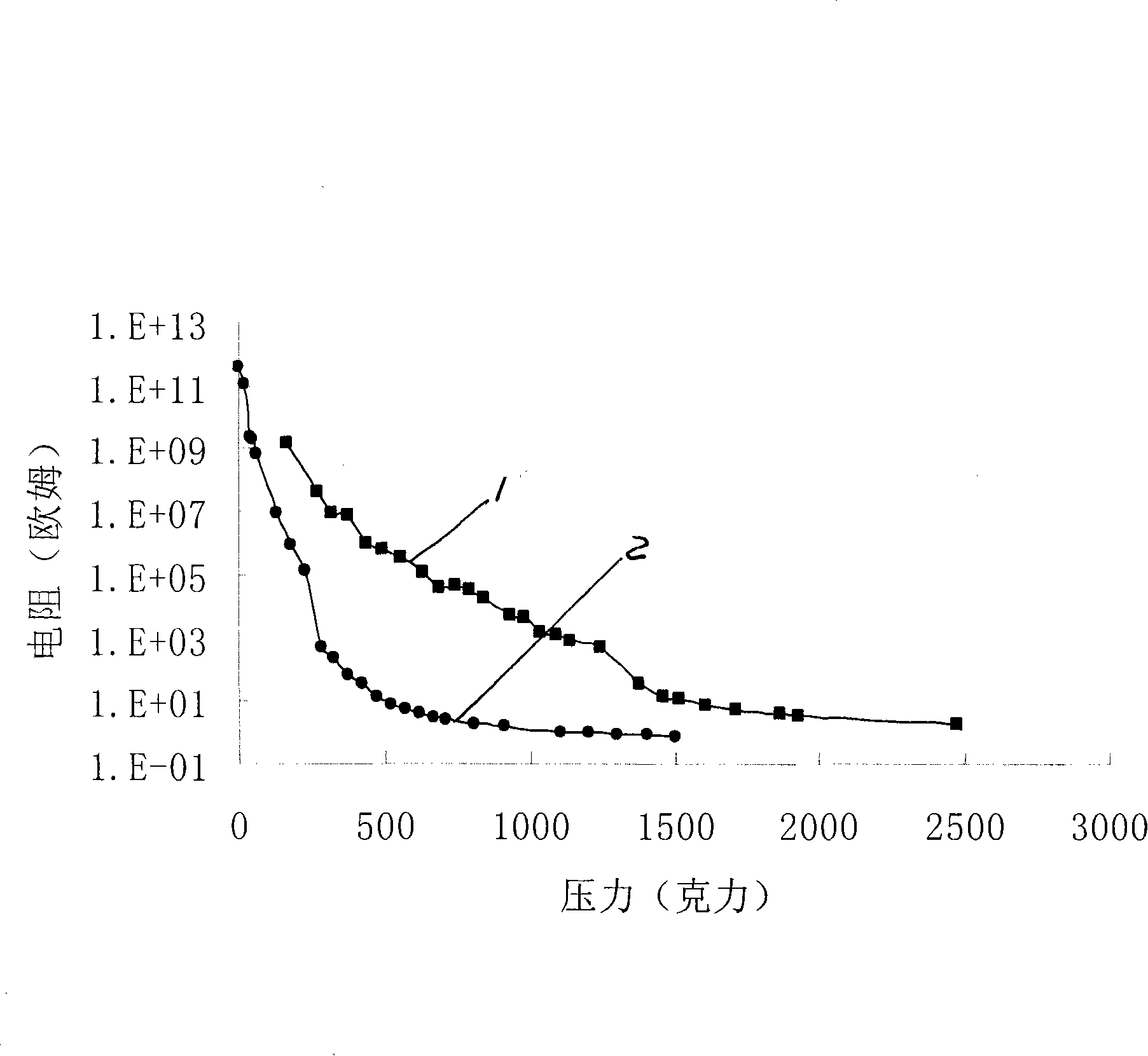

Pressure-sensitive conductive rubber and method of preparing the same

A conductive rubber and silicone technology, applied in the field of conductive materials, can solve the problems of high cost, difficulty in applying robots, and large temperature effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0010] (1) Ingredients, each component by weight ratio, take 1 part of mold silica gel, 2 parts of 200 mesh nickel powder and dilute with an appropriate amount of 99.8% concentration of toluene, stir evenly until it is viscous (you can see the halo formed when stirring ), try to avoid the sinking of nickel powder.

[0011] (2) For the first curing, add 0.012 parts of curing agent to the above-mentioned viscous rubber, cover it and put it in a constant temperature box at 50°C for the first curing, and take it out after 4 hours (the colloid should be relatively wet when taken out) , crushed.

[0012] (3) For the second curing, add 0.024 parts of curing agent to the above powder, stir and mix, and cure in a 30°C thermostat for 48 hours to produce the pressure-sensitive conductive rubber of the present invention.

Embodiment 2

[0014] (1) Ingredients, each component by weight ratio, take 1 part of mold silica gel, 2.5 parts of 200 mesh nickel powder, will nickel powder and 0.035 part of 200 mesh ZrO 2 Put it into a mortar and grind until fully mixed, then mix it into the mold silica gel and dilute it with an appropriate amount of 99.8% toluene, stir evenly until it becomes viscous (you can see the halo formed during stirring), try to avoid the nickel powder from sinking.

[0015] (2) For the first curing, add 0.012 parts of curing agent to the above-mentioned viscous rubber, cover it and put it in a constant temperature box at 70°C for the first curing, and take it out after 4 hours (the colloid should be relatively wet when taken out) , crushed.

[0016] (3) For the second curing, add 0.028 parts of curing agent to the above powder, stir and mix, and cure in a 40°C thermostat for 48 hours to produce the pressure-sensitive conductive rubber of the present invention.

Embodiment 3

[0018] (1) Ingredients, each component by weight ratio, take 1 part of mold silica gel, 3 parts of 200-mesh nickel powder, nickel powder and 0.04 part of 200-mesh ZrO 2 Put it into a mortar and grind until fully mixed, then mix it into the mold silica gel and dilute it with an appropriate amount of 99.8% toluene, stir evenly until it becomes viscous (you can see the halo formed during stirring), try to avoid the nickel powder from sinking.

[0019] (2) For the first curing, add 0.012 parts of curing agent to the above-mentioned viscous rubber, cover it and put it in an incubator at 80°C for the first curing, and take it out after 3.5 hours (the colloid should be relatively wet when taken out) , crushed.

[0020] (3) For the second curing, add 0.034 parts of curing agent to the above powder, stir and mix, and cure in a constant temperature oven at 50°C for 48 hours to produce the pressure-sensitive conductive rubber of the present invention.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com