Flexible pressure-sensitive layer, preparation method and application

A pressure-sensitive layer, flexible technology, applied in the field of pressure detection, can solve the problems of small measurement range, large environmental pollution, complex pressure-sensitive layer preparation process, etc., to improve sensitivity and measurement range, improve dielectric properties and pressure-sensitive properties. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] like Figure 4 As shown, a preparation method of a flexible pressure-sensitive layer, the preparation method includes,

[0031] preparing a mold, the mold includes a side wall and a bottom wall, and a cavity enclosed by the side wall and the bottom wall;

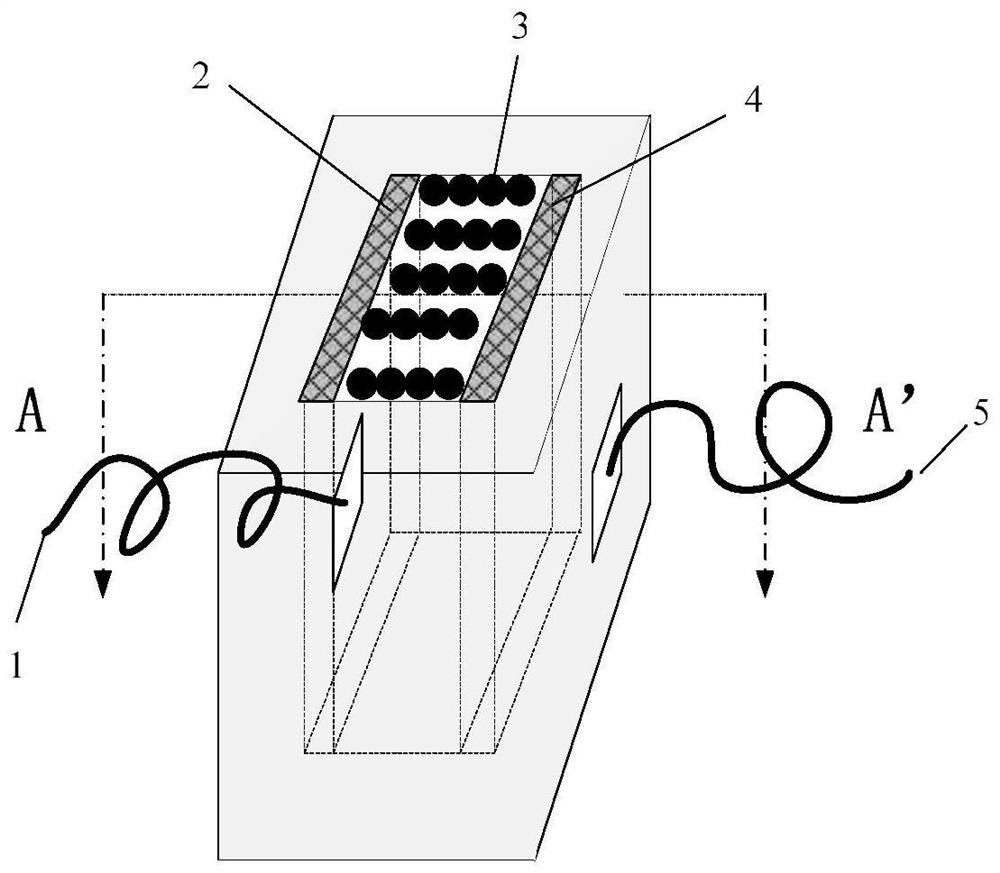

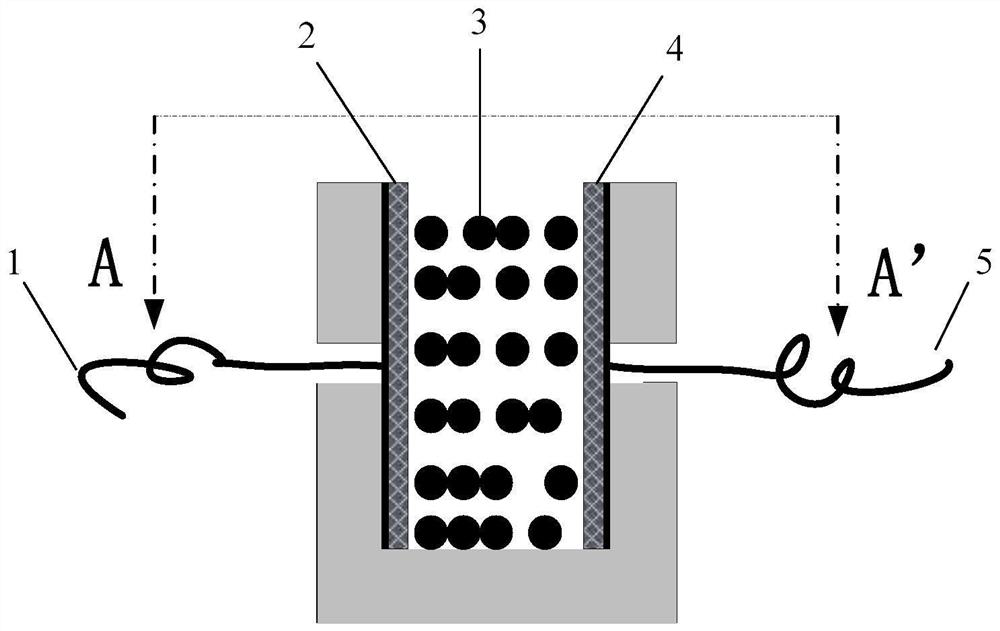

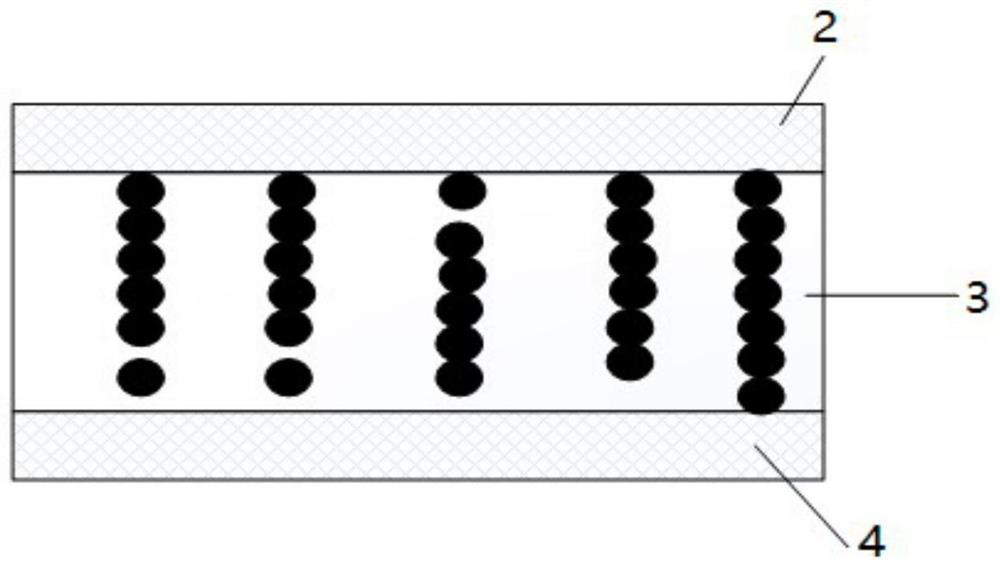

[0032] In this example, as Figure 1 to Figure 3 As shown, the mold is printed by, for example, a 3D printer, and the size of the mold is 2cm*2cm*0.5cm. A through hole is provided on the opposite side wall, the through hole is used to draw out the electrode lead for applying the electric field, and the cavity enclosed by the side wall and the bottom wall is used to hold the prepared blended liquid.

[0033] The piezoelectric ceramics are pasted in the mold, and the piezoelectric ceramics are respectively pasted on a pair of opposite side walls of the mold in the cavity, and the piezoelectric ceramics respectively include sides passing through the pasted mold. wall extraction electrodes;

[0034] In this embodiment...

Embodiment 2

[0049] This embodiment provides a flexible pressure-sensitive layer, a preparation method and application thereof. The difference between this embodiment 2 and embodiment 1 is:

[0050] In the process of preparing the mixed solution, the nanoparticles are selected as nano-dielectric, the mass of the nano-dielectric is 25% of the mass of the solvent, and the solvent is epoxy resin.

[0051] During curing of the blend, different curing conditions are employed. Specifically, under the condition that the heating plate is kept at 60 degrees Celsius, the value of the voltage applied to the lead-out electrodes on the piezoelectric ceramic is 2.5KV, and when the temperature of the heating plate is kept constant at 60 degrees Celsius and the value of the voltage applied to the piezoelectric ceramic is 2.5KV , the curing of the blended liquid requires 4 hours to be completely cured, and the completely cured blended liquid is taken out from the mold to obtain the flexible pressure-sensi...

Embodiment 3

[0053] This embodiment provides a flexible pressure-sensitive layer, a preparation method and application thereof. The difference between this embodiment 3 and embodiment 2 is:

[0054] In the process of preparing the mixed solution, the nanoparticles are selected as nano metal particles, the mass of the nano metal particles is 5% of the mass of the solvent, and the solvent is polyester resin.

[0055] During curing of the blend, different curing conditions are employed. Specifically, under the condition that the heating plate is kept at 80 degrees Celsius, the value of the voltage applied by the piezoelectric ceramics is 4KV, and when the temperature of the heating plate is kept constant at 80 degrees Celsius and the value of the voltage applied to the piezoelectric ceramics is 4KV, the curing of the blend requires 2 After 1 hour, it was fully cured, and the fully cured blend liquid was taken out from the mold to obtain the flexible pressure-sensitive layer.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com