Normal temperature adhesive composition and preparation method thereof

A composition and normal temperature technology, applied in adhesive types, natural rubber adhesives, ester copolymer adhesives, etc., can solve the problem of narrow applicability of sealing adhesive products, inability to use products in a wide range, use hygiene and problems Issues such as applicability of broad restrictions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

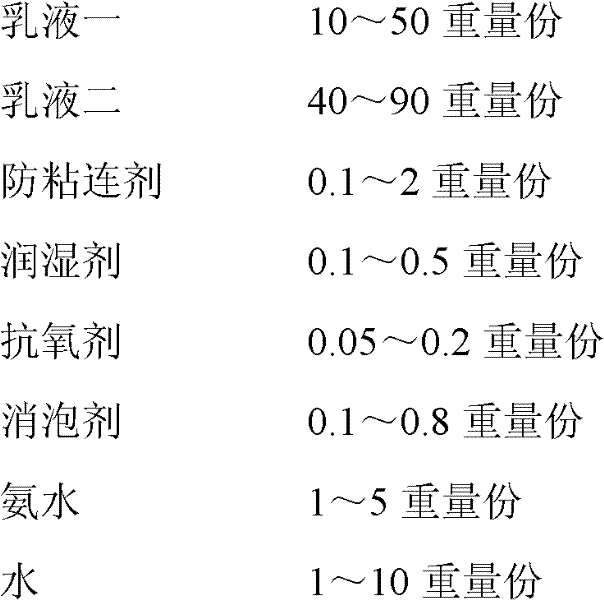

[0025] This embodiment provides a kind of normal temperature adhesive composition, can be used as the sealing glue used in the package, specifically take each raw material according to the weight ratio in the following formula:

[0026] Emulsion 1 10-50 parts by weight

[0027] Emulsion II 40-90 parts by weight

[0028] Antiblocking agent 0.1~2 parts by weight

[0029] Wetting agent 0.1~0.5 parts by weight

[0030] Antioxidant 0.05~0.2 parts by weight

[0031] Defoamer 0.1~0.8 parts by weight

[0032] Ammonia 1~5 parts by weight

[0033] Water 1~10 parts by weight

[0034] Emulsion 1 in the above formula is any one of silicon-acrylic emulsion, pure acrylic emulsion, styrene-acrylic emulsion, vinegar-acrylic emulsion, vinyl acetate-ethylene copolymer emulsion (VAE emulsion), and the molecular weight of this emulsion 1 is less than 100,000. The glass transition temperature of one is -2~+45℃;

[0035] Emulsion 2 in the above formula is any one of acrylic emulsion, SIS late...

Embodiment 2

[0062] This embodiment provides a normal temperature adhesive composition, which can be used as a sealant in packaging. Specifically, the raw materials of the normal temperature adhesive composition are obtained according to the following formula:

[0063] join in

order

parts by weight

number (g)

molecular weight

glass transition temperature

(℃)

1

natural rubber latex

66

>700,000

-60~-70

2

Styrene acrylic emulsion

23

<100,000

0~10

3

talcum powder

0.8

4

DO-75 (wetting agent)

0.5

5

Polymeric Hindered Phenols and Thioesters

Antioxidant (water-based antioxidant

Agent SD-1688)

0.1

6

1551 (mineral oil defoaming

agent)

0.25

7

5

8

water

4.35

[0064] The preparation method of normal temper...

Embodiment 3

[0067] This embodiment provides a normal temperature adhesive composition, which can be used as a sealant in packaging. Specifically, the raw materials of the normal temperature adhesive composition are obtained according to the following formula:

[0068] join in

order

parts by weight

number (g)

molecular weight

glass transition temperature

degree(℃)

1

SIS latex

62

>400,000

-60~-70

2

Vinegar Acrylic Emulsion

27

<100,000

-2~15

3

1.4

4

DO-75 (wetting agent)

0.4

5

Polymerization of hindered phenols with sulfur

Ester antioxidant (water

SD-1688)

0.1

6

1551 (defoamer)

0.25

7

2

8

water

6.85

[0069] The preparation method of normal temperature adhesive compo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com