Converse measuring method and device based on axial direction stereovision

A stereo vision and measurement device technology, applied in the field of reverse measurement and devices based on axial stereo vision, can solve problems such as the complexity of homologous feature matching algorithms, and achieve the effects of simple structure, simplified matching process, and low equipment cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

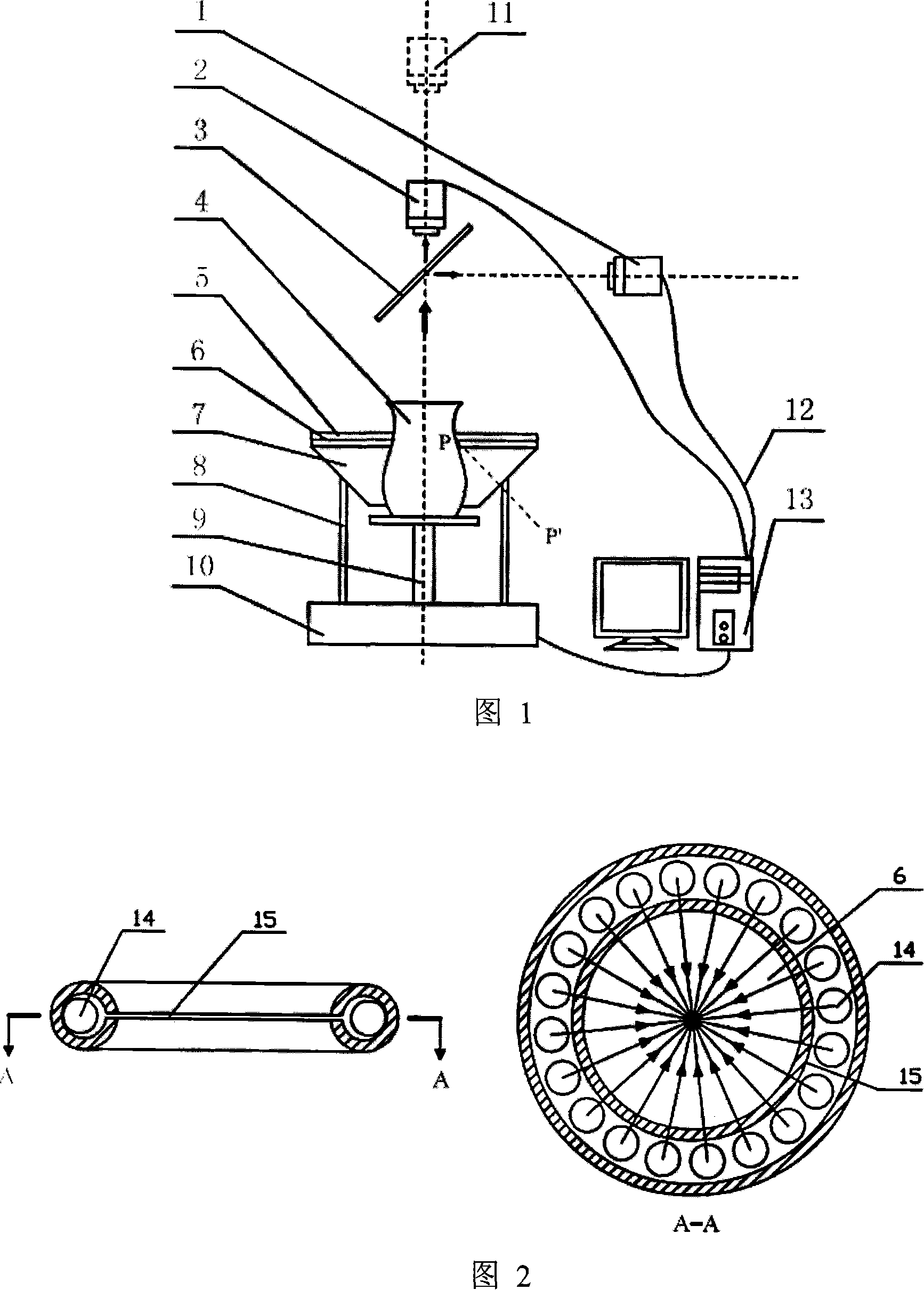

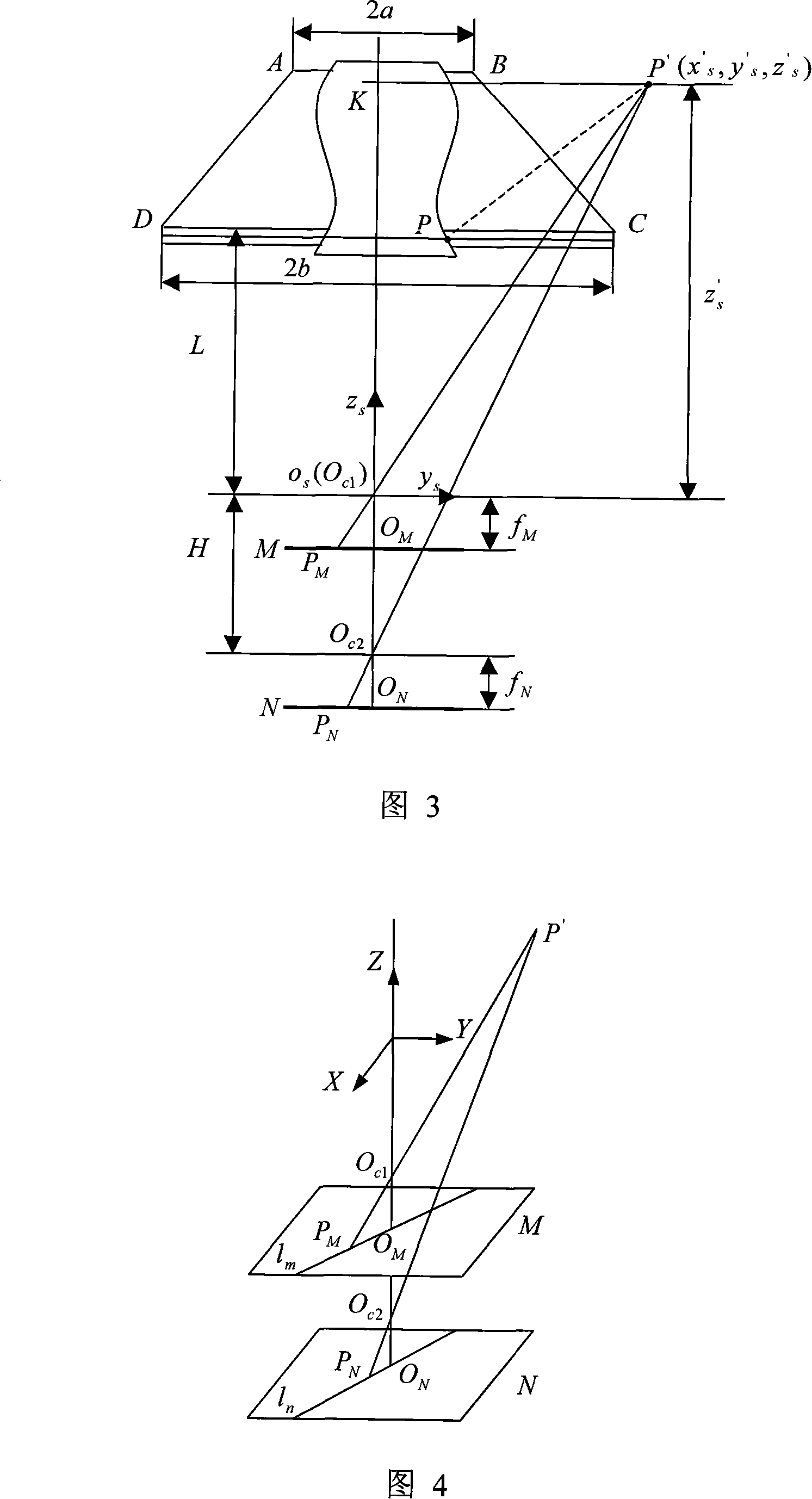

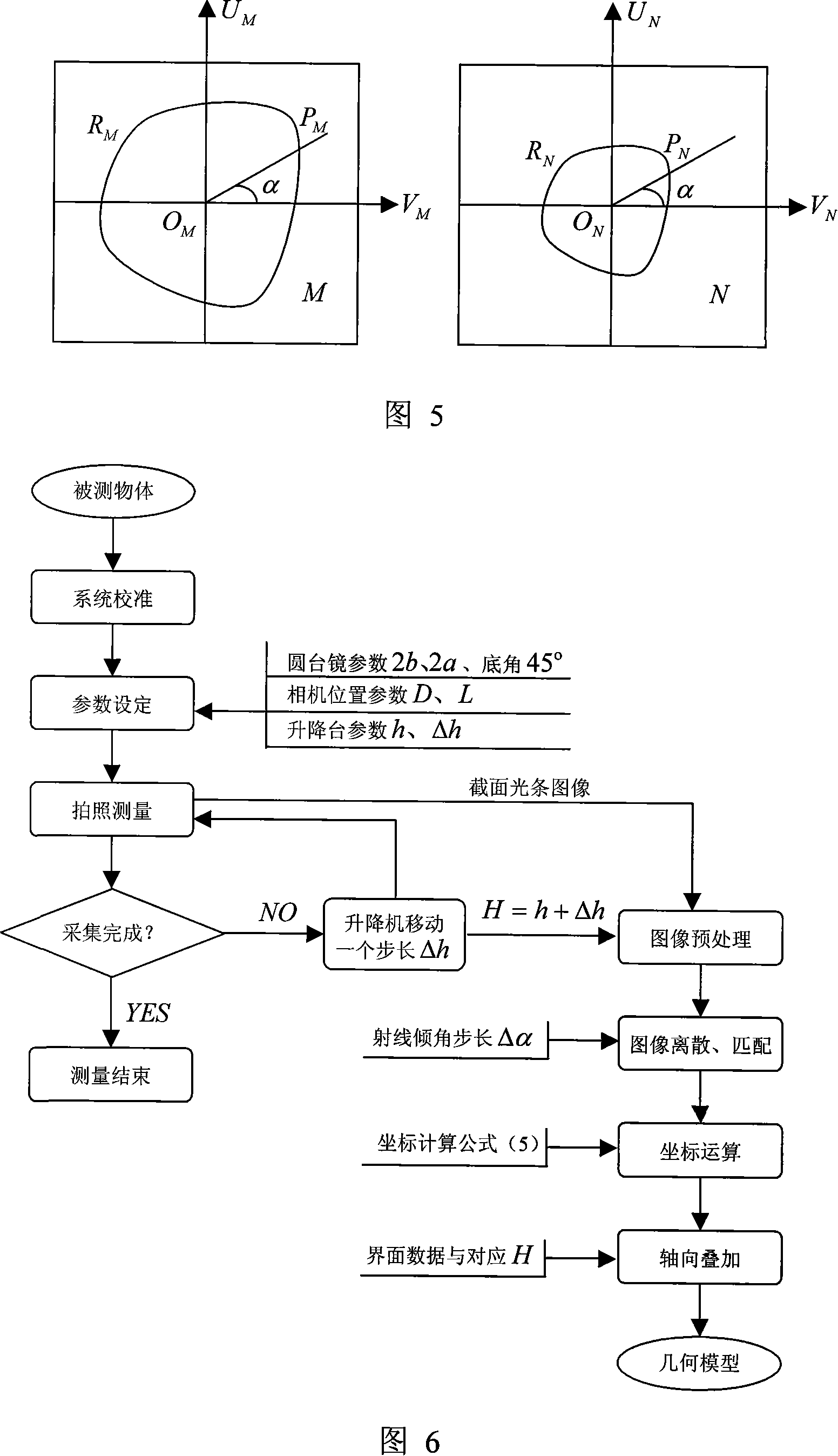

[0023] As shown in Fig. 1 and Fig. 2, the far-axis camera 1 and the paraxial camera 2 are placed on the top of the circular platform inner mirror 7, and the axes of the two cameras are perpendicular to each other, and a circular beam splitter 3 is arranged at the intersection of the two axes, The far-axis camera 1 is farther away from the circular beamsplitter 3 than the paraxial camera 2, and the two cameras can move on their respective axes; the large bottom of the circular table inner mirror 7 faces upwards and is supported by a bracket 8, and the top of its large bottom is equipped with Circular plane structured light generator 5, a lifting mechanism 9 at the bottom of the inner mirror 7 of the round table, the object 4 to be measured is placed on the lifting mechanism 9 and located in the inner mirror 7 of the round table, and the bracket 8 and the lifting mechanism 9 are arranged on the base 10; Frame camera and lifting mechanism 9 are all connected with computer 13 with ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bottom corner | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com