Processing device for biaxially stretched polyvinyl alcohol film and matching method thereof

A polyvinyl alcohol film and biaxial stretching technology, which is applied in the preparation of polyvinyl alcohol film and the processing device field of biaxially stretched polyvinyl alcohol film, can solve the problem of easy slippage, high melt strength, and difficulty in stretching PVA film. problems such as magnification processing, to achieve the effect of reducing the process of quenching and secondary heating, the supporting process is simple, and the value of industrial production is good

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0065] This example is a specific implementation method for preparing a biaxially stretched polyvinyl alcohol film with a transverse stretch ratio of 4.5 and a longitudinal stretch ratio of 3.5, wherein the raw materials of the polyvinyl alcohol film are self-made:

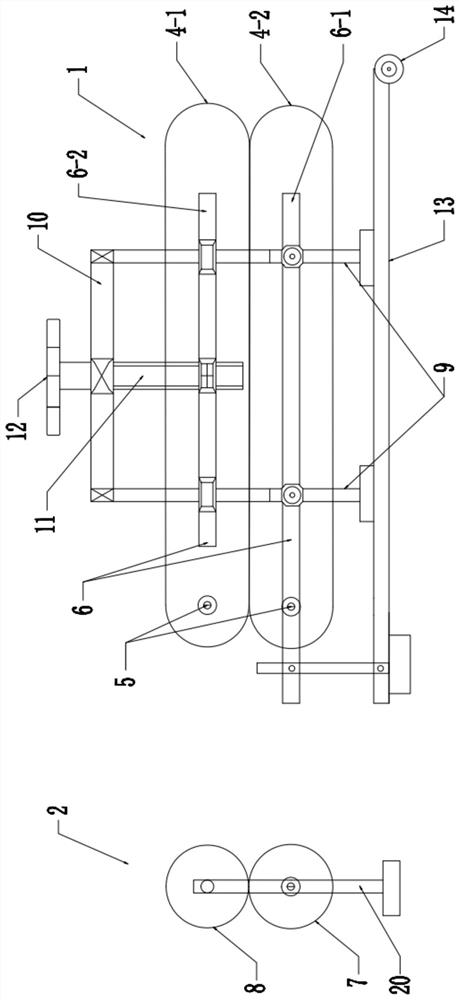

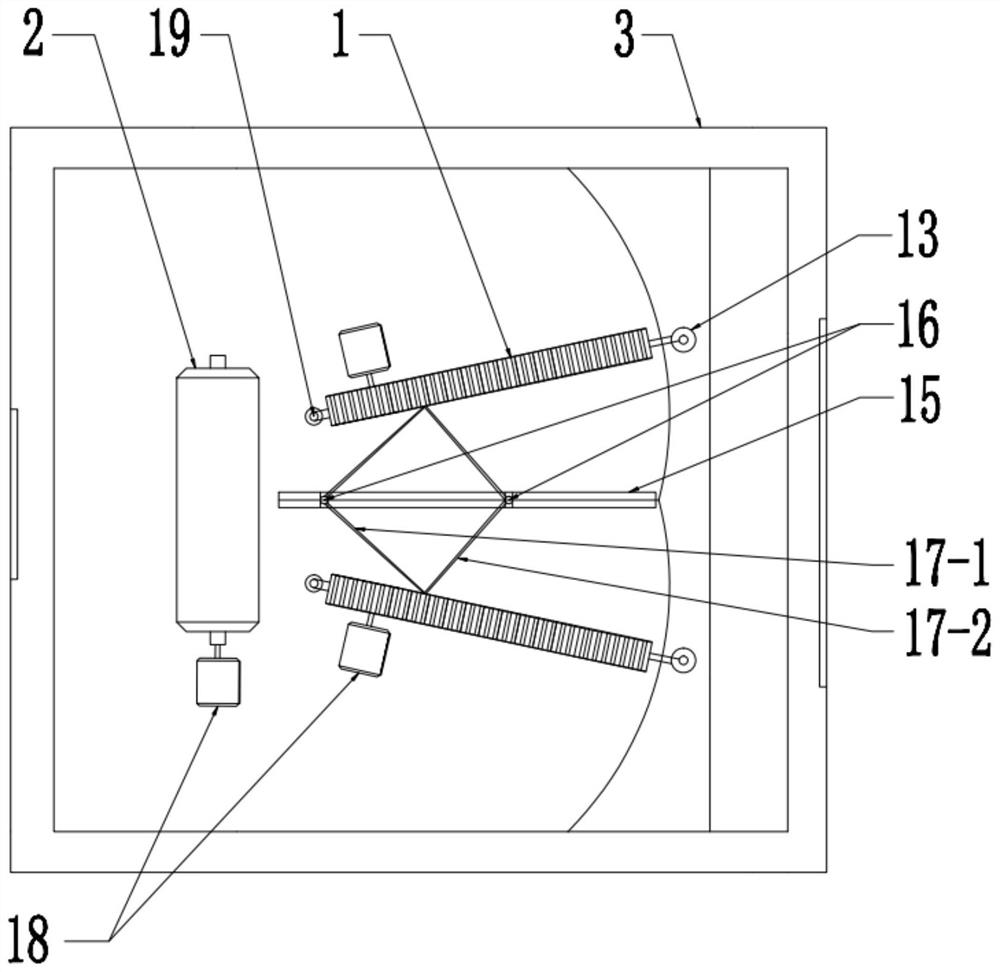

[0066] Such as figure 1 , figure 2 As shown, a processing device for biaxially stretching polyvinyl alcohol film includes two sets of meshing crawler mechanisms 1, heating rollers 2, meshing clamping force adjustment components, opening angle adjustment components, main body base 3 and transmission motor 18,

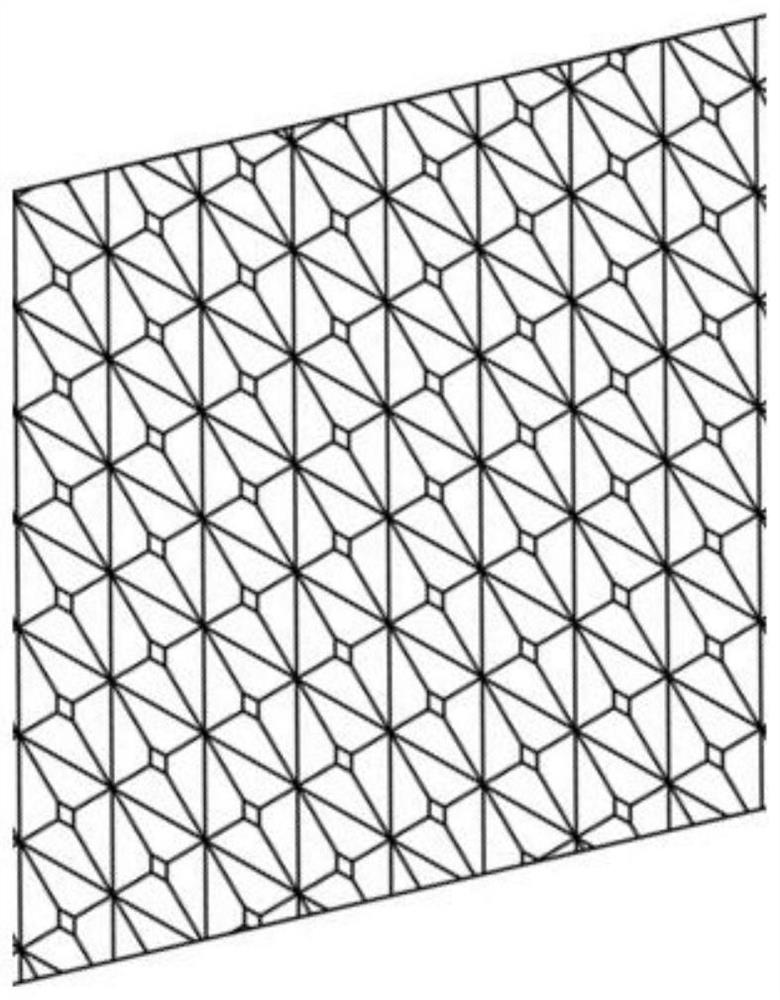

[0067] Each group of said engaging crawler mechanism 1 includes two clamping tracks (4-1, 4-2) that are engaged with each other. The clamping track is driven by the crawler drive roller 5 and is provided with an engaging structure on the surface, and the two clamping tracks (4-1, 4-2) rotate in opposite directions at the same speed, clamp and drive the film to be processed by the contact surface at the mes...

Embodiment 2

[0093] This example is a specific implementation method for preparing a biaxially stretched polyvinyl alcohol film with a transverse stretch ratio of 3.0 and a longitudinal stretch ratio of 2.5, wherein the raw materials of the polyvinyl alcohol film are self-made:

[0094] A processing device for biaxially stretched polyvinyl alcohol film, including two sets of meshing crawler mechanisms, heating roller sets, meshing clamping force adjustment components, opening angle adjustment components, a main body base and a transmission motor,

[0095] Each set of meshing crawler mechanisms includes two gripping crawlers that mesh with each other. The gripping crawler is driven by the crawler drive roller and has an engaging structure on the surface, and the two gripping crawlers rotate in opposite directions at the same speed. The film to be processed is clamped and driven by the contact surface. The length of the contact surface engaged with each other is 100 cm, and the width is 5 cm....

Embodiment 3

[0117] This example is a specific implementation of preparing a biaxially oriented polypropylene film with a transverse stretch ratio of 2.0 and a longitudinal stretch ratio of 1.5, wherein the raw material used is polypropylene T30s (Maoming Petrochemical).

[0118] A processing device for biaxially stretching polyvinyl alcohol film, including two sets of meshing crawler mechanisms, heating roller sets, meshing clamping force adjustment components, a main body base and a transmission motor,

[0119] Each set of meshing track mechanism includes two clamping tracks that are engaged with each other. The clamping track is driven by the track drive roller and has an engaging structure on the surface, and the two clamping tracks rotate in opposite directions at the same speed. The film to be processed is clamped and driven by the contact surface. The length of the contact surface engaged with each other is 50cm, and the width is 2cm. The clamping track is fixed by the side support p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com