Light source with replaceable lamp wick

A technology for light source devices and wicks, which can be applied to projection devices, optics, instruments, etc., and can solve the problems of high cost, high production cost of reflectors, and poor cooling performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

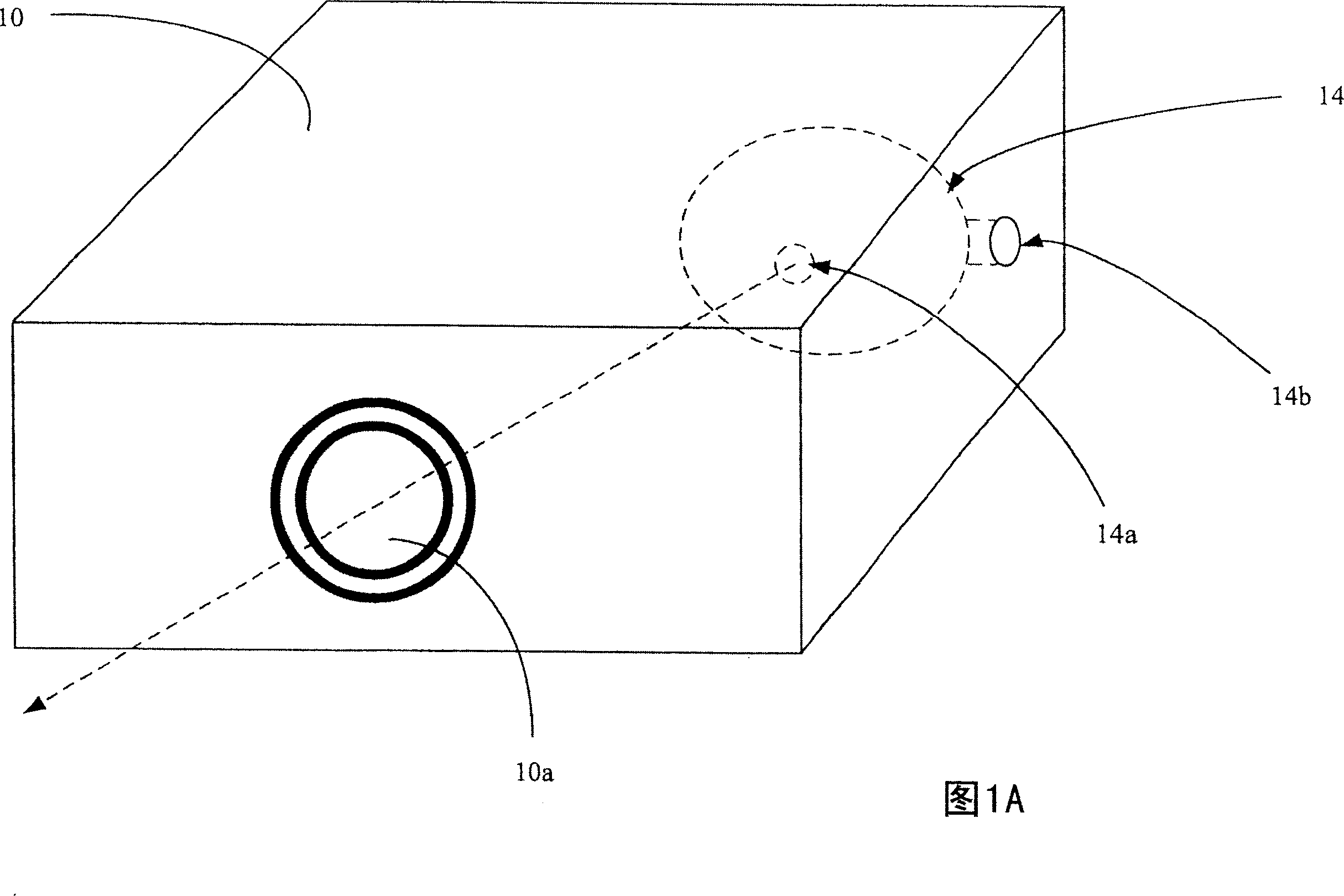

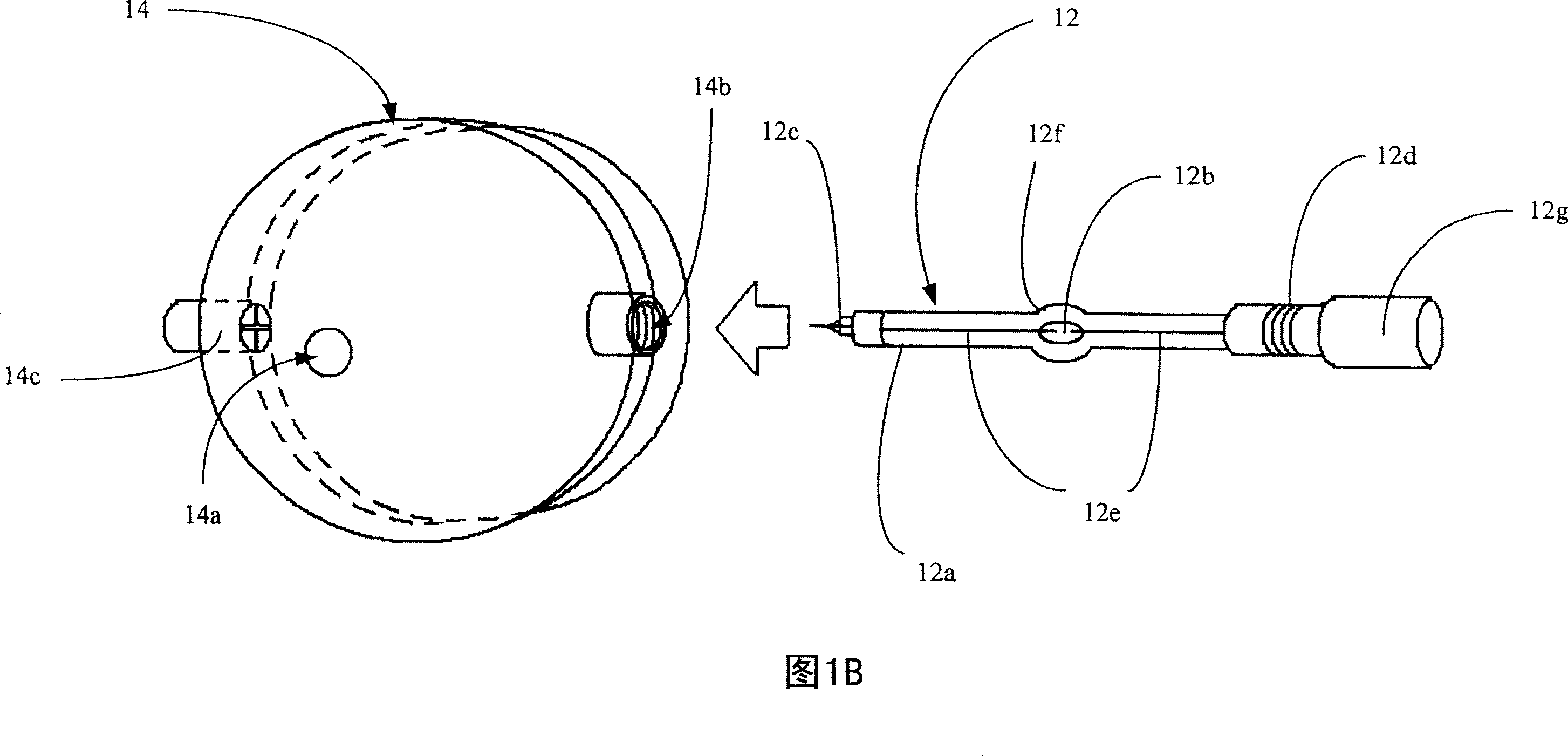

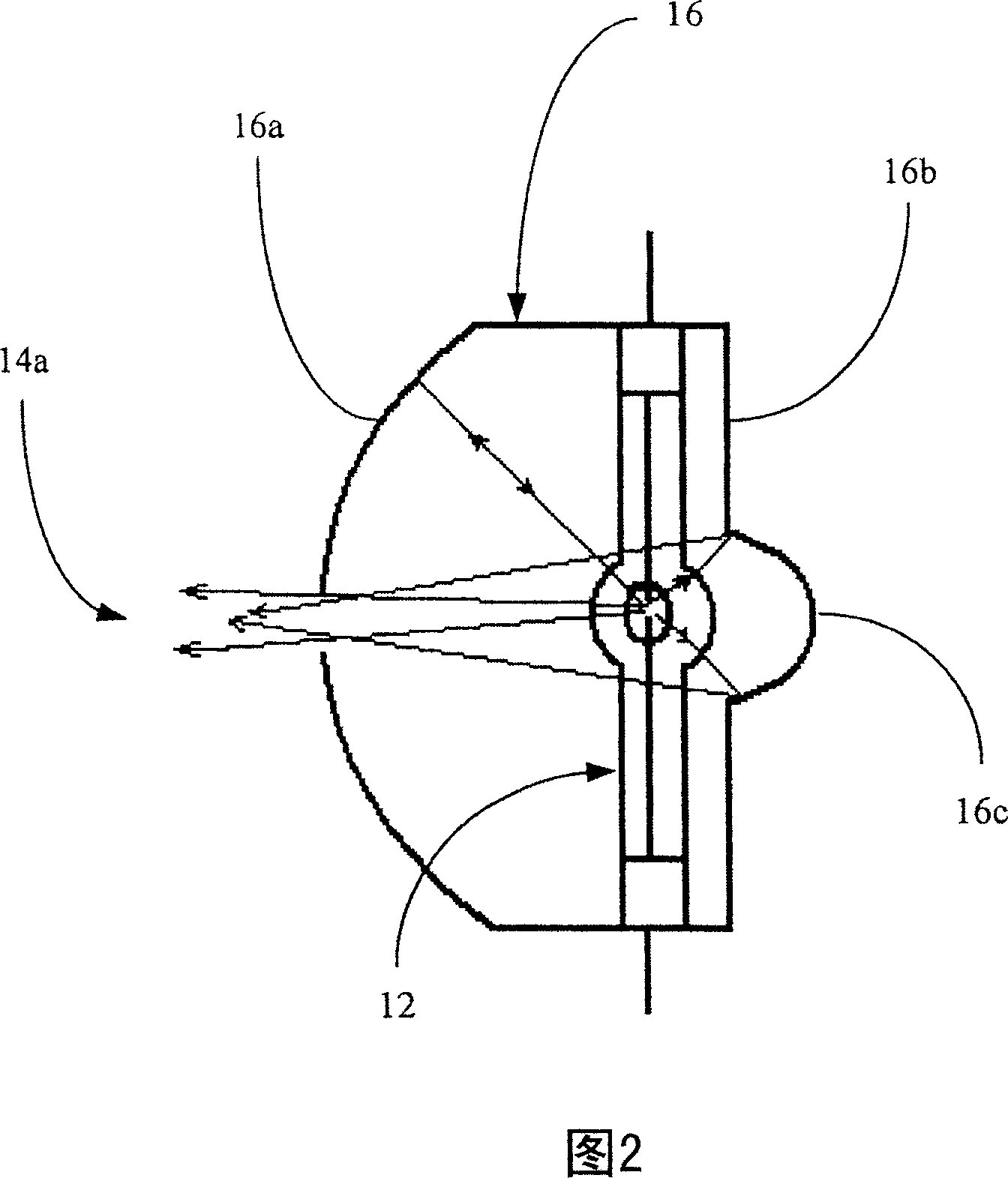

[0027] Please refer to FIGS. 1A-1B . FIGS. 1A-1B are schematic diagrams of a projector based on a light source device with a replaceable wick according to the present invention. As shown in FIG. 1A , the projector 10 of the present invention is mainly composed of a light source 12 (as shown in FIG. 1B ), a lampshade 14 , and a projection lens 10 a of the light source device with replaceable wicks of the present invention. The lampshade 14 is installed inside the projector 10 , and all the positioning port electrode holders 14 b can be observed from the appearance of the projector 10 .

[0028] As shown in FIG. 1B , the light source 12 is mainly composed of a wick tube 12 a , a wick 12 b , and electrode pairs 12 e extending from the wick 12 b in two directions. The electrode pair 12e is electrically connected to the electrode cap 12d and the cross electrode 12c at both ends of the wick tube 12a, and the handle portion 12g is extended from the electrode cap 12d. The wick tube 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com