Hydrocarbons pyrolysis coking judgment pilot experimental device

A high-temperature cracking, hydrocarbon technology, used in cracking, non-catalytic thermal cracking, petroleum industry and other directions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

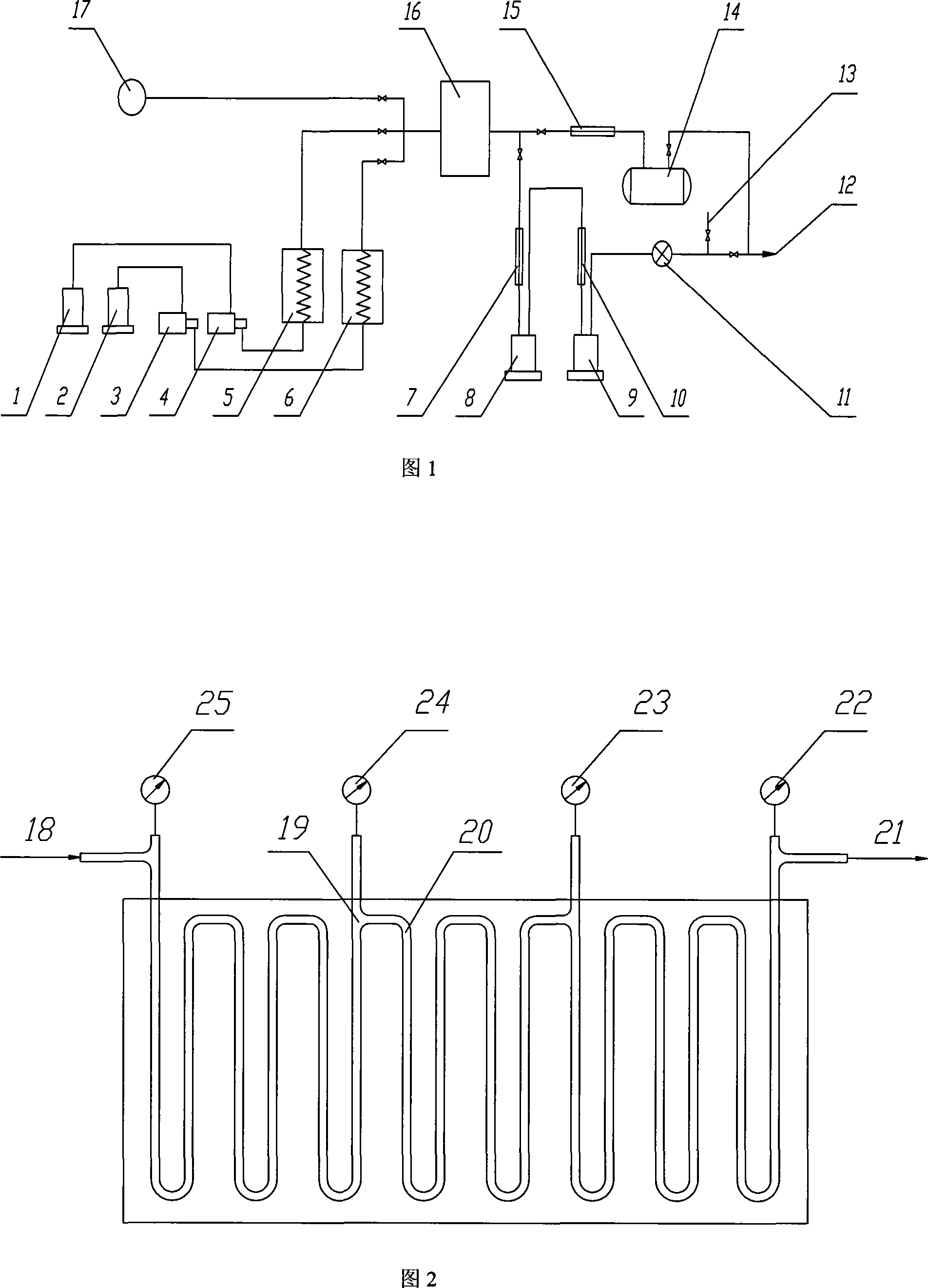

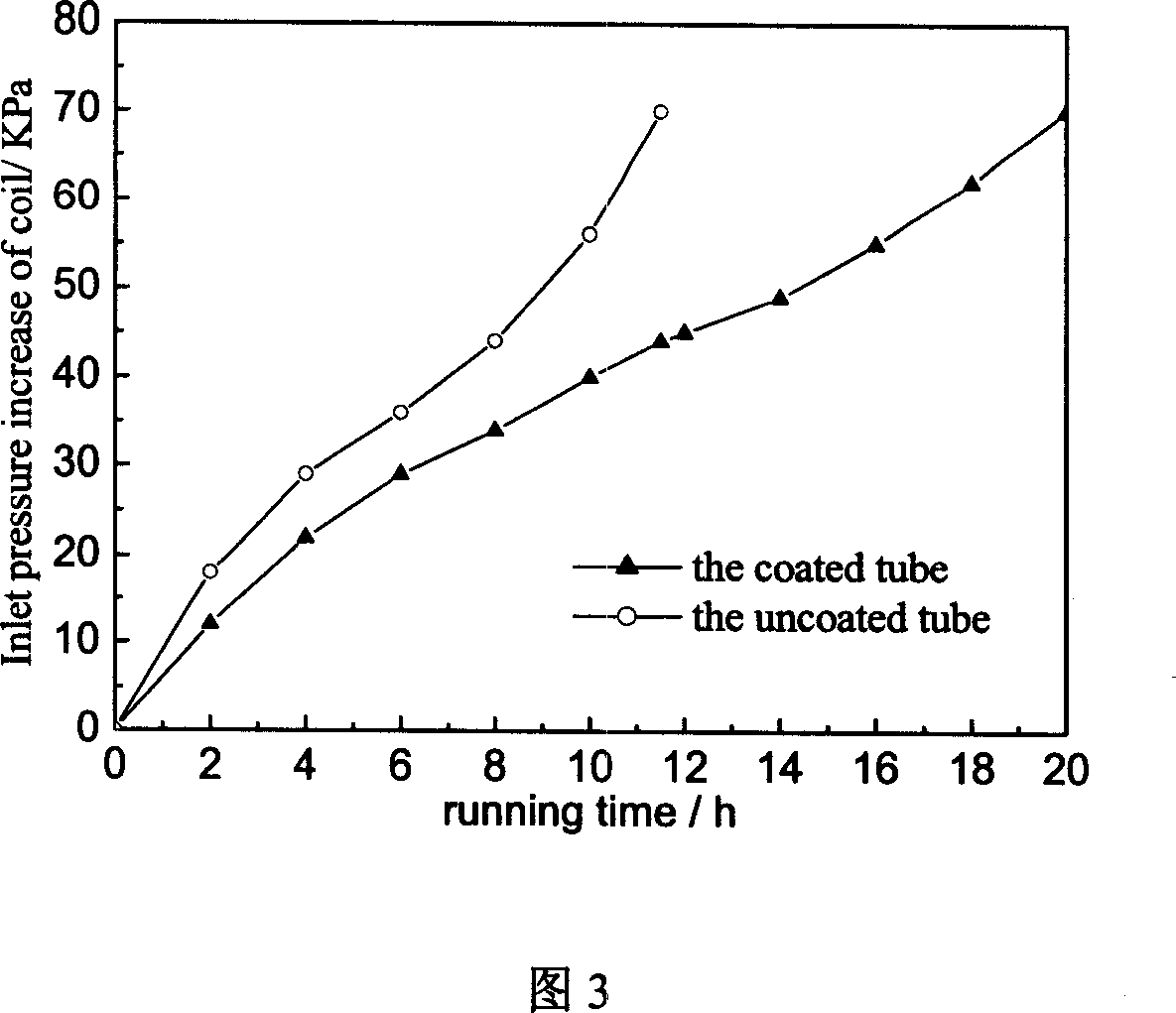

[0016] In the present invention, the deionized water metering pump and the cracking raw material metering pump are respectively connected with the outlets of the deionized water storage tank and the cracking raw material storage tank; The outlet of the pump is respectively connected to the inlet pipelines of the deionized water vaporizer and the cracking raw material gasifier; after gasification, the two gases converge at the outlet of the gasifier, and the merged pipeline is connected with the inlet pipeline of the preheating section; After the gas is preheated in the preheating section, the outlet pipe of the preheating section is connected to the inlet pipe of the cracking section, and the superheated gas undergoes cracking reaction in the cracking section, and coke deposits on the tube wall; the outlet pipe is connected to the inlet of the primary water cooling device , so that the cracked high-temperature gas is rapidly cooled, and the coolant enters the primary coolant st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com