Thermal transfer printing wood grain foil and method for making same

A technology of thermal transfer printing and thermal transfer layer, which is applied in patterned paper, textiles and papermaking, fiber raw material processing, etc., can solve the problems of low adhesion, high price, high brittleness, etc., and achieve clear texture and enhanced protection function , Excellent light and weather resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

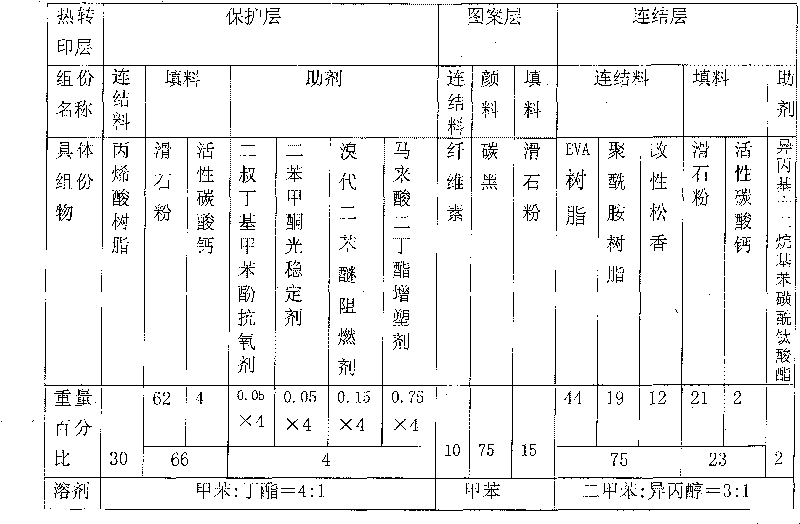

Embodiment 1

[0031]

[0032] In Example 1, the tape base is a high-strength polyester film with a thickness of 19 μm, and the total thickness of the thermal transfer wood grain foil is 51 μm. The column of the weight percentage of fillers, additives, and linking materials in the protective layer and the connecting layer is divided into upper and lower columns. The upper column is the weight percentage of each specific component in the layer, and the lower column is the filler or additive. The percentage by weight of the total filler or auxiliary agent in this layer after the addition of each specific component. Among them, the columns on the additives in the protective layer are multiplicative formulas, and the multiplicands 0.05, 0.05, 0.15, and 0.75 represent the weight percentages of the additives in each specific component, such as 0.75 represents dibutyl maleate plasticizer Accounting for the weight percent of auxiliary agent is 75%, and four multiplicands add up to be equal to 1, ...

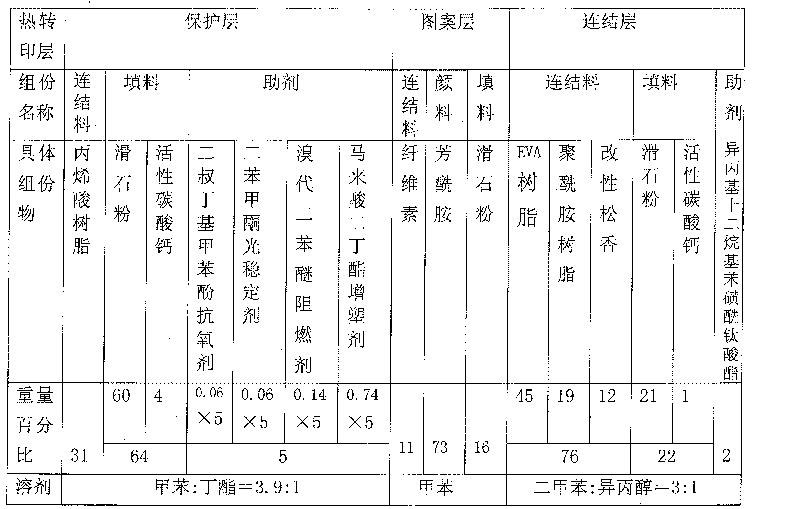

Embodiment 2

[0034]

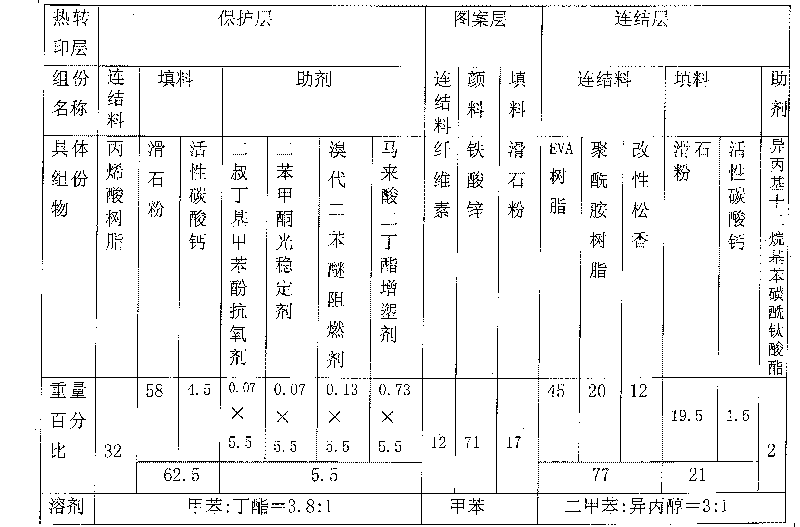

Embodiment 3

[0036]

[0037] In Examples 2 and 3, the tape base is a high-strength polyester film with a thickness of 20 μm, and the total thickness of the thermal transfer wood grain foil is 52 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com