Magnetic suspension device used for measuring spherical spinner pole axis deflection angle and measurement method thereof

A technology of polar axis declination and spherical rotor, which is applied in the direction of measuring device, using electric/magnetic device to transmit sensing components, using electric device, etc., can solve the problems of high difficulty, high technical difficulty and high installation accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

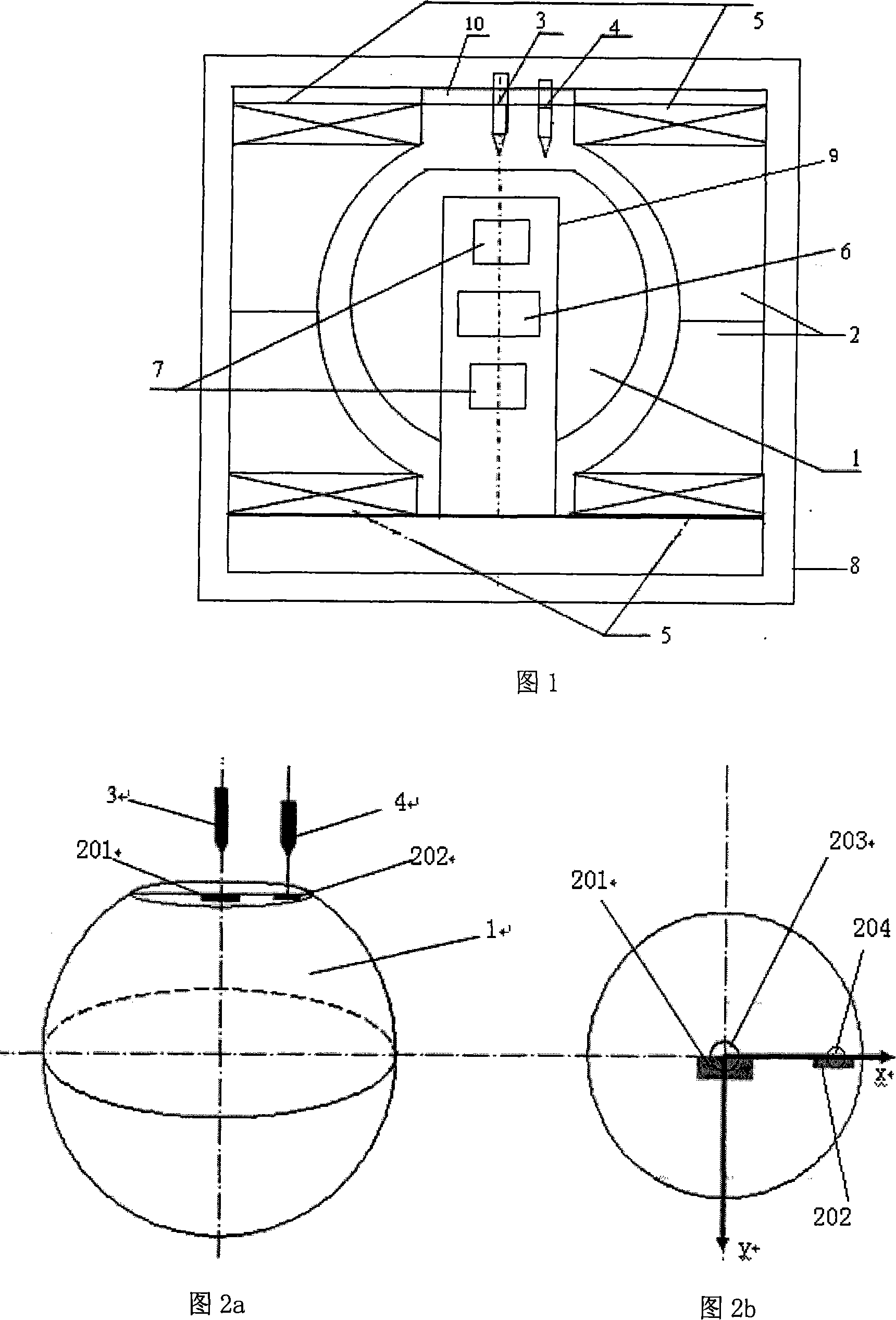

[0018] As shown in Figure 1, the low-temperature superconducting magnetic levitation device of the present invention includes: superconducting niobium ball rotor 1, niobium tile 2, polar axis optical fiber sensor 3, rotational speed optical fiber sensor 4, superconducting coil 5, superconducting motor 6, torque device 7 , low temperature Dewar 8, center column 9, copper plate 10. The cryogenic Dewar 8 located on the outermost layer of the device is cooled by cryogenic liquid helium, providing a 4.2K cryogenic environment for the entire system. The upper and lower niobium tiles 2 with spherical inner surfaces are arranged opposite to each other to form a spherical cavity. The hollow superconducting niobium ball rotor 1 is located in the spherical cavity and sleeved on the central column 9 . A superconducting motor 6 and two torque devices 7 ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com