Method for manufacturing heat conducting module

A technology of heat conduction module and manufacturing method, which is applied in the direction of cooling/ventilation/heating transformation, semiconductor devices, semiconductor/solid-state device components, etc., and can solve the problem of loosening and separation of heat pipes and heat conduction plates, poor heat conduction performance, and clamping force Minor problems, to achieve the effect of ensuring holding stability and adhesion, and improving heat conduction performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

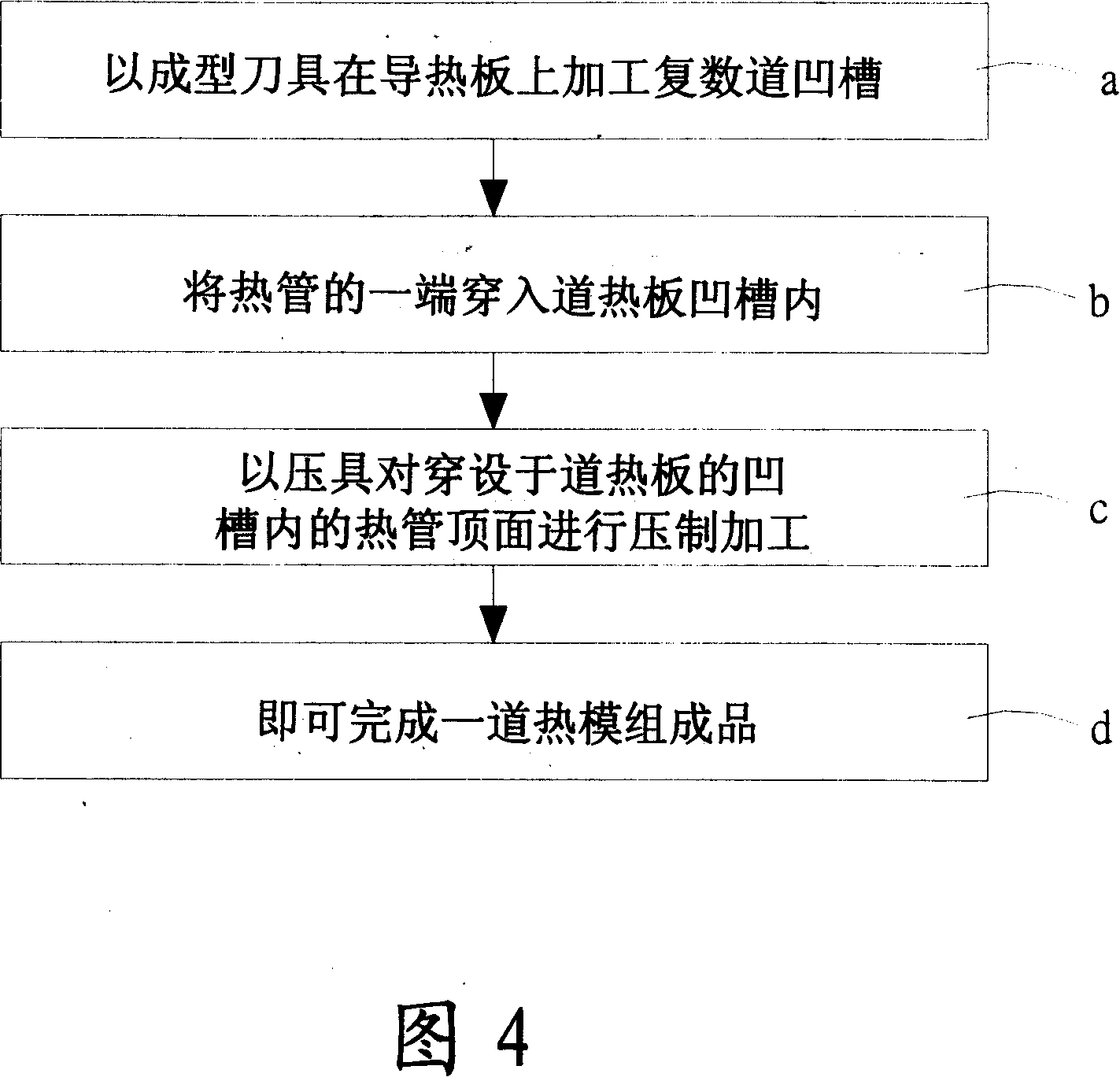

[0039] Relevant detailed description and technical content of the present invention, cooperate drawing description as follows:

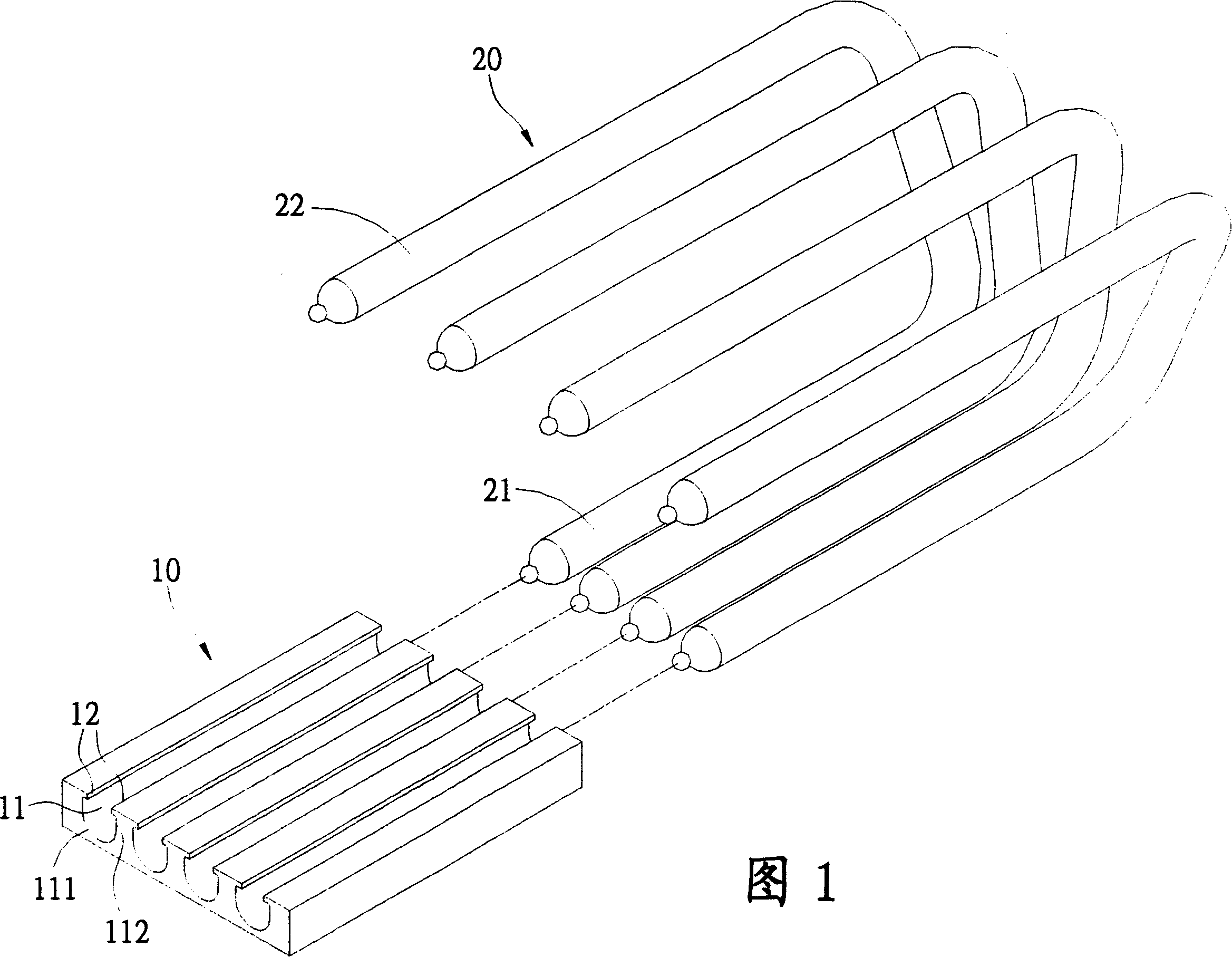

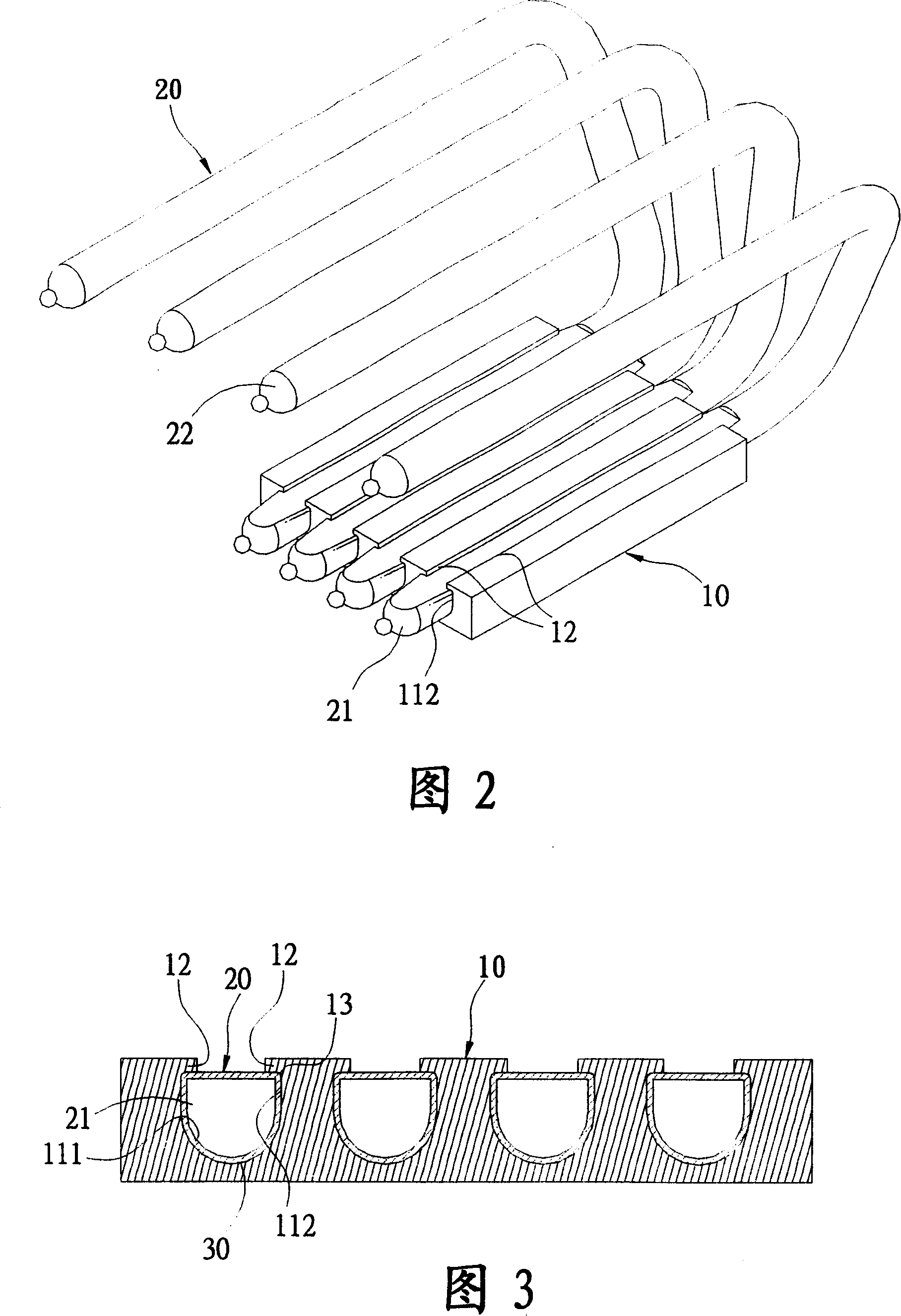

[0040] Please refer to Figures 1 to 3, which are three-dimensional exploded views, combined schematic diagrams and combined cross-sectional views of the present invention. The present invention provides a heat conduction module and its manufacturing method. The heat conduction module mainly includes a heat conduction plate 10 with a plurality of heat pipes 20, wherein:

[0041] The heat conduction plate 10 is a rectangular body with good heat dissipation such as aluminum or copper, and a plurality of grooves 11 parallel to each other are provided on its top surface, and each groove 11 runs through the front and back of the heat conduction plate 10 respectively. The end face, and an arc-shaped surface 111 is formed below it, and longitudinal surfaces 112 are respectively extended upwards at both ends of the arc-shaped surface 111; An inner fillet 13 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com