Substrate processing method, substrate processing apparatus and control program

A substrate processing method and a substrate processing device technology, which are applied in semiconductor/solid-state device manufacturing, liquid chemical plating, coating, etc., and can solve problems such as complex conveying mechanism, multiple process times, and narrow process window

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0161] Hereinafter, embodiments of the present invention will be described with reference to the drawings. In addition, the same or similar reference numerals are assigned to the same or corresponding components in each figure, and overlapping descriptions are omitted.

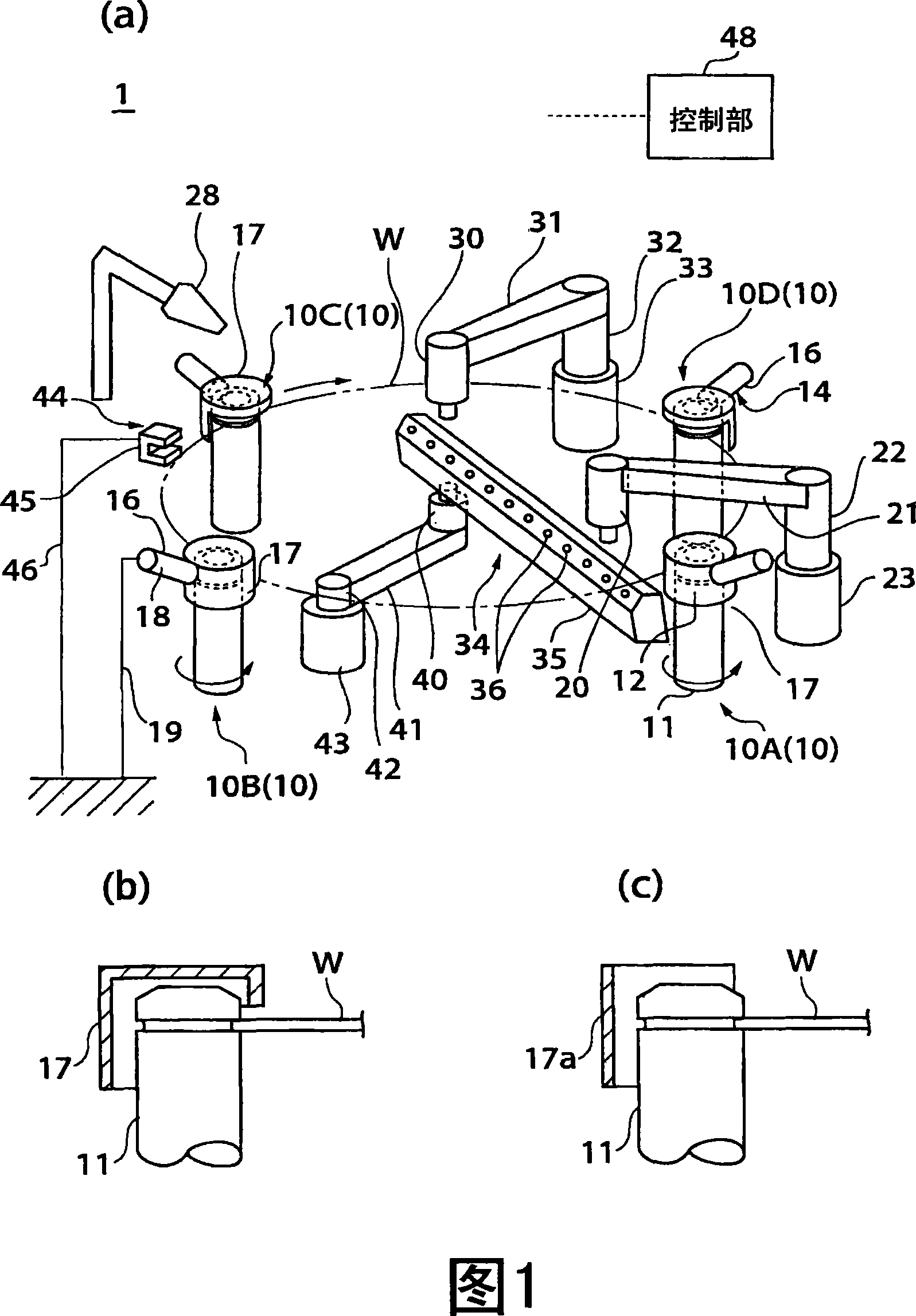

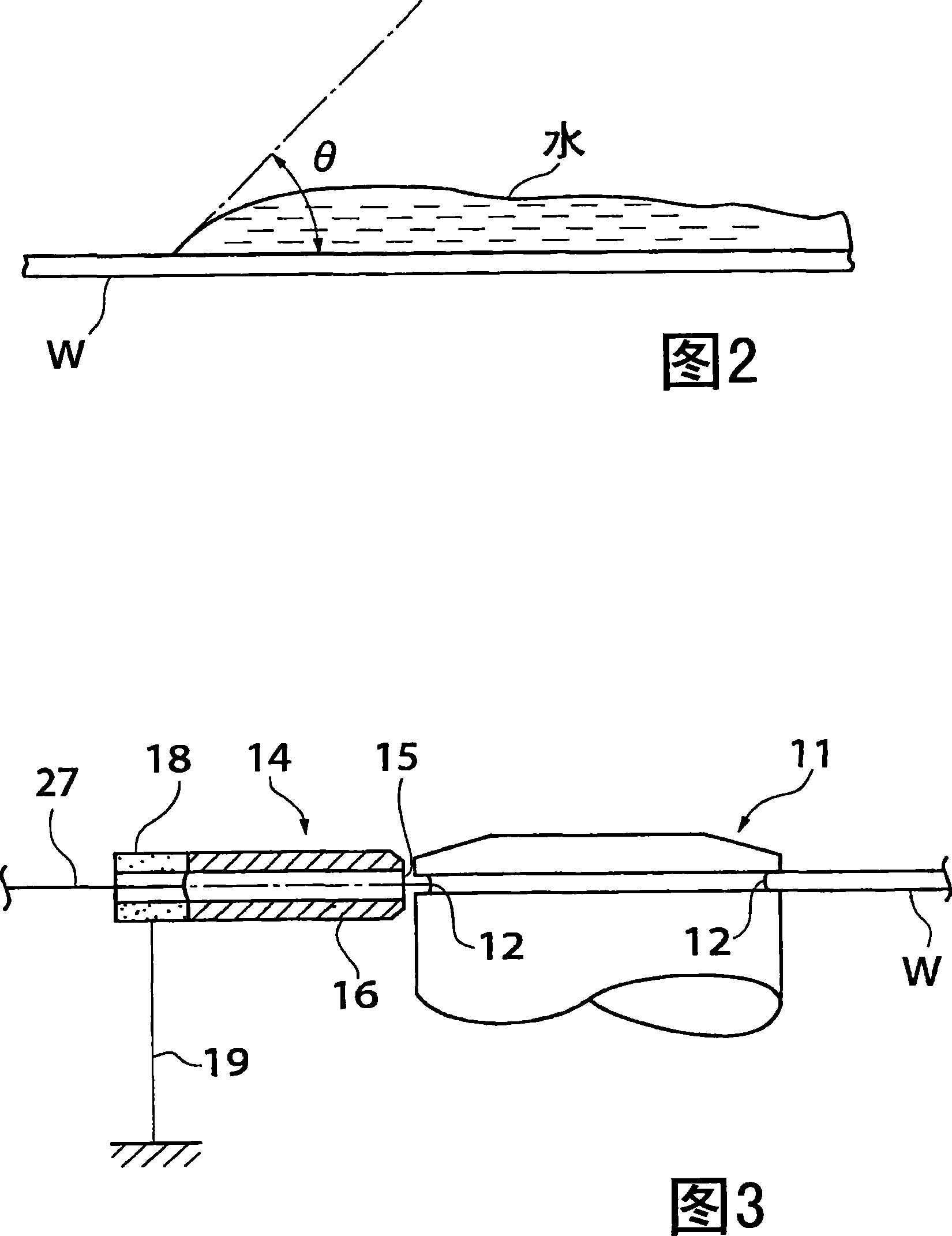

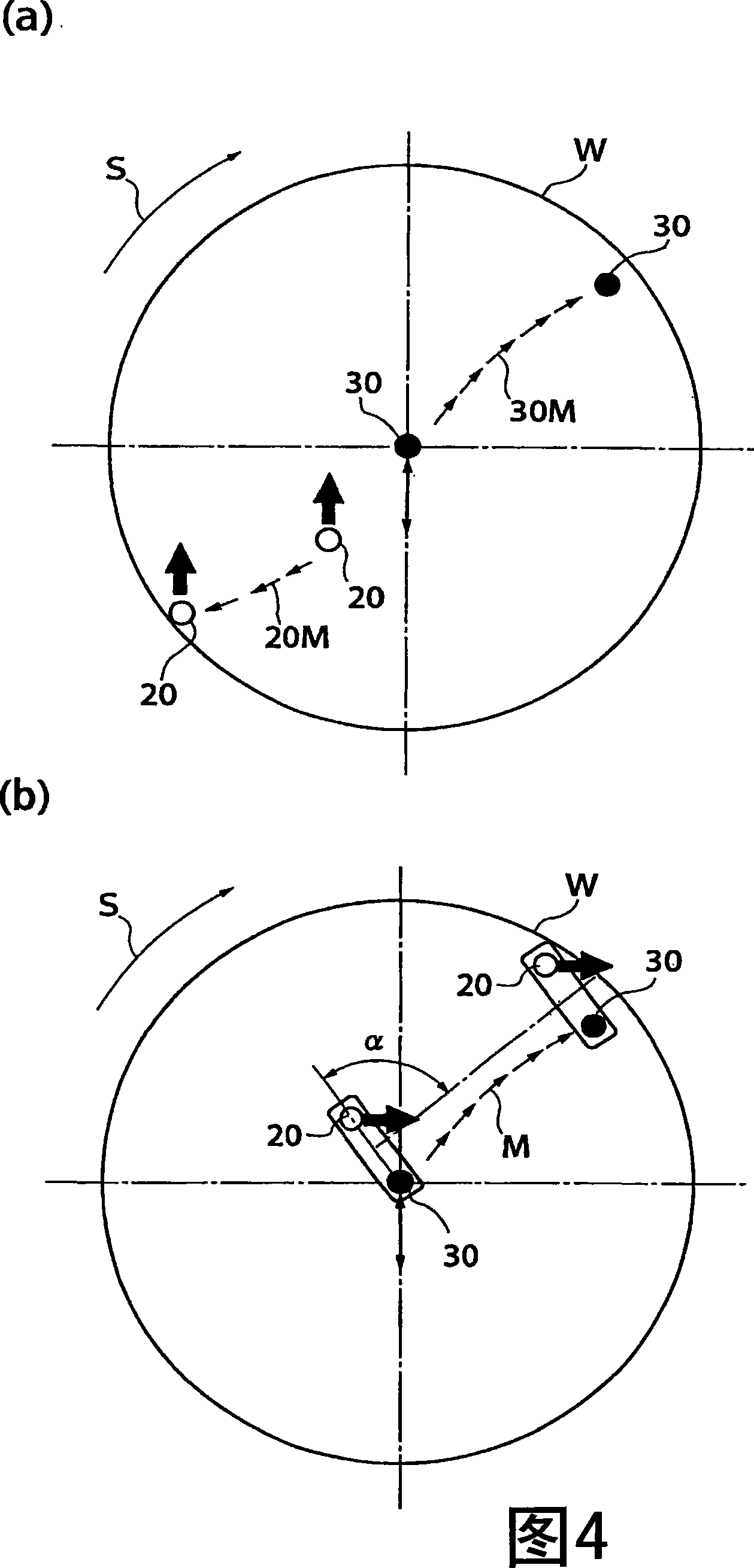

[0162] FIG. 1( a ) is a schematic perspective view of a substrate processing apparatus 1 according to an embodiment of the present invention. The substrate processing apparatus 1 includes a substrate holding unit 10 that holds and rotates a substrate W (shown by a two-dot chain line in FIG. The fixed rinse nozzle 28 for the upper surface of the rinse water supply nozzle, the upper air supply nozzle 30 for supplying drying air to the upper surface of the substrate W, and the lower surface of the rinse water supply nozzle for supplying cleaning water to the lower surface of the substrate W. The multi-hole rinsing nozzle 34, the lower air supply nozzle 40 for supplying drying gas to the lower surface of the subs...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com