Oil and wax removal powder and preparation method thereof

A technology of wax powder and surfactant, applied in the field of metal surface cleaning, can solve the problems of corroded metal, poor rust resistance, and easy rust of metal parts, etc., and achieve the effect of reducing difficulty, preventing oxidation, and good water washability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

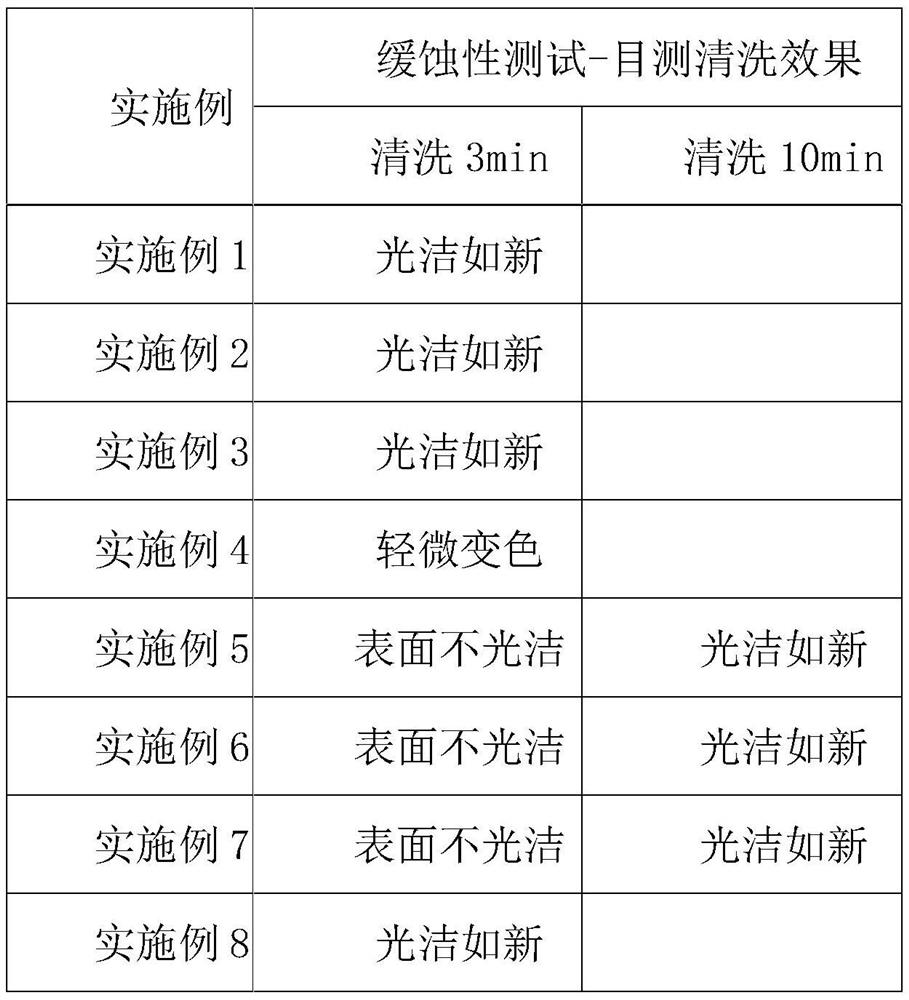

Examples

preparation example Construction

[0073] In one embodiment, a kind of preparation method of degreasing and dewaxing powder, comprises the following steps:

[0074] S1. Add 3-7 parts of thickener, 23-32 parts of chelating agent, and 6-10 parts of corrosion inhibitor to the mixer for dispersion, and mix and disperse for 1-8 minutes to form mixture A; the dispersion speed of the mixer is 500-800r / min;

[0075] S2. Add 30-40 parts of basic compound, 9-18 parts of surfactant, and 1-3.5 parts of emulsifier to the mixer for dispersion, and mix and disperse for 1-8 minutes to form mixture B; the dispersion speed of the mixer is 500-800r / min;

[0076] S3, in mixture A and mixture B, mix and stir 1-8min, obtain mixture C; Described agitator dispersing speed is 500-800r / min;

[0077] S4, adding 8-12 parts of cleaning aids to mixture C, mixing and stirring for 1-8 minutes, to obtain degreasing and wax-removing powder; the dispersing speed of the mixer is 500-800 r / min.

[0078] In a preferred embodiment, a kind of pr...

Embodiment 1

[0085] A degreasing and wax removing powder, comprising the following raw materials in parts by weight: 20 parts of sodium bicarbonate, 15 parts of sodium carbonate, 8 parts of sodium gluconate, 15 parts of sodium metasilicate pentahydrate, and 12 parts of APSM layered sodium silicate parts, 8 parts of sodium dodecyl benzene sulfonate, 5 parts of fatty alcohol ethoxylate, 5 parts of coconut oil monoethanolamide, 2 parts of LS-20 emulsion wax, and 10 parts of borax.

[0086] The CAS number of the sodium bicarbonate is 144-55-8.

[0087] The CAS number of the sodium carbonate is 5968-11-6.

[0088] The sodium gluconate was purchased from Shanghai Yuanye Biotechnology Co., Ltd., and the CAS number was 527-07-1.

[0089] The sodium metasilicate pentahydrate was purchased from Wuhan Jiyesheng Chemical Co., Ltd., and the CAS number was 10213-79-3.

[0090] The APSM layered sodium silicate was purchased from Linyi Xidi Auxiliary Co., Ltd.

[0091]The sodium dodecylbenzenesulfonate...

Embodiment 2

[0104] A degreasing and wax removing powder, comprising the following raw materials in parts by weight: 17 parts of sodium bicarbonate, 13 parts of sodium carbonate, 6 parts of sodium gluconate, 13 parts of sodium metasilicate pentahydrate, and 10 parts of APSM layered sodium silicate parts, 6 parts of sodium dodecylbenzene sulfonate, 3 parts of fatty alcohol ethoxylate, 3 parts of coco acid monoethanolamide, 1 part of LS-20 emulsion wax, and 8 parts of borax.

[0105] The CAS number of the sodium bicarbonate is 144-55-8.

[0106] The CAS number of the sodium carbonate is 5968-11-6.

[0107] The sodium gluconate was purchased from Shanghai Yuanye Biotechnology Co., Ltd., and the CAS number was 527-07-1.

[0108] The sodium metasilicate pentahydrate was purchased from Wuhan Jiyesheng Chemical Co., Ltd., and the CAS number was 10213-79-3.

[0109] The APSM layered sodium silicate was purchased from Linyi Xidi Auxiliary Co., Ltd.

[0110] The sodium dodecylbenzenesulfonate is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com