Crude organosilicone oil, silicon-containing stiffening agent and preparation methods for crude organosilicone oil and silicon-containing stiffening agent

An organosilicon and stiffening agent technology, applied in the direction of improved hand-feeling fibers, textiles and papermaking, fiber processing, etc., can solve the problems of no slippery feeling, no washability, no thick feeling, etc., and achieve a thick feel and excellent washability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

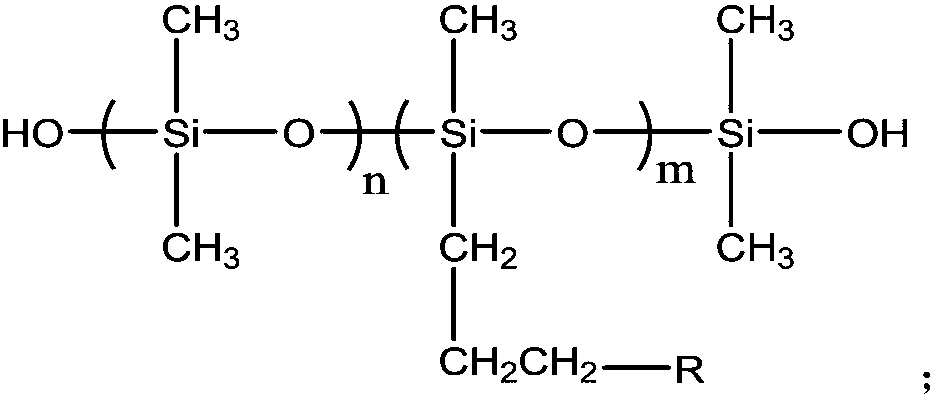

[0027] A preparation method of the organosilicon crude oil, first react linear silane and silane coupling agent at 100-115°C for 1-3h, add a basic catalyst, turn on the vacuum, raise the temperature to 130-140°C, and continue vacuuming After reacting for 10-20 hours, a silicone crude oil with a viscosity greater than 1 million mPa.s at 100°C is obtained, which is translucent solid at room temperature.

[0028] As an improvement, the linear silane used is Dow Corning's linear body PMX 0156 or Wacker's linear body WS62M.

[0029] As an improvement, the amount of the silane coupling agent is 0.05-0.15% by weight of the linear silane.

[0030] As an improvement, the amount of the basic catalyst is 0.05-0.5% of the linear silane weight;

[0031] The basic catalyst is any one or a mixture of potassium hydroxide, sodium hydroxide and lithium hydroxide.

[0032] A silicon-containing stiffener, comprising the following raw materials in parts by weight: 10-30 parts of organic silicon ...

Embodiment 1

[0039] A preparation method of silicon-containing stiffening agent, comprising the following steps:

[0040] 1) In a 1L four-necked flask equipped with a thermometer, a condenser and an electric stirrer, add 500g of linear body PMX0156 and 0.4g of 3-(2-aminoethyl)-aminopropylmethyldimethoxysilane at 110 React at ℃ for 2 hours, then add 1.0g of potassium hydroxide solution with a concentration of 50%, turn on the vacuum and raise the temperature, react at 135℃ for 12h, measure the viscosity, and the online viscometer between 100-120℃ shows more than 1 million mPa.s, Viscosity is qualified (translucent solid when cooled to normal temperature), add 15g propylene glycol butyl ether into the flask, continue to stir for 1h, and obtain intermediate crude oil Ⅰ;

[0041] 2) Add 100g of polyvinyl acetate (PVAC), 150g of ethyl acetate, and 250g of intermediate crude oil I into a 2L beaker equipped with a condensation system, a disperser, and a homogenizer, start the disperser, and stir ...

Embodiment 2

[0043] A preparation method of silicon-containing stiffening agent, comprising the following steps:

[0044] 1) In a 1L four-neck flask equipped with a thermometer, a condenser and an electric stirrer, add 500g of linear WS62M and 0.3g of y-glycidyl ether propylmethyldimethoxysilane, and react at 110°C for 1h. Then add 1.0g of lithium hydroxide, turn on the vacuum and heat up, react at 140°C for 16h, measure the viscosity, the online viscometer between 100°C and 120°C shows more than 1 million mPa.s, the viscosity is qualified (it is translucent solid when cooled to normal temperature), Add 10 g of diethylene glycol butyl ether into the flask, and continue stirring for 1 h to obtain intermediate crude oil II;

[0045]2) Add 80g of polyvinyl acetate (PVAc), 100g of ethyl acetate, and 300g of intermediate crude oil II into a 2L beaker equipped with a condensation system, a disperser, and a homogenizer, start the disperser, and stir at 1500 rpm 0.5h, then add 22g of C13 isomeric...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com