Surface treatment process of garment textile fabric

A textile fabric and surface treatment technology, applied in fiber treatment, textiles, papermaking, plant fibers, etc., can solve the problems of high price, achieve good washability, avoid sudden drop in anti-fouling performance, and improve anti-fouling performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

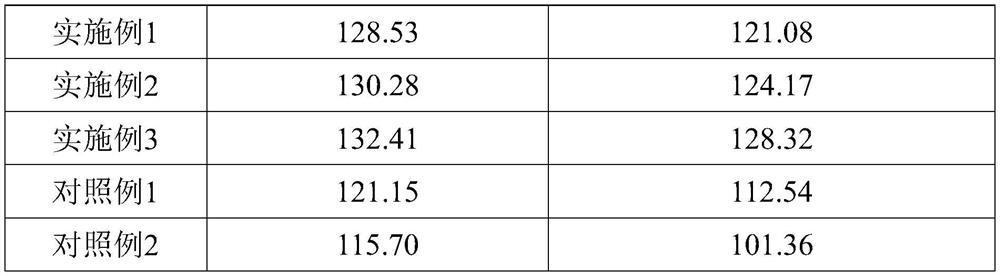

Embodiment 1

[0026] (1) Soak 5 kg of pure cotton fabric in 50 kg of 1-butyl-3-methylimidazolium dicyandiamide salt solution with a mass concentration of 10%, heat to 80° C. for 1 hour, and dry to complete the pretreatment of the fabric.

[0027] (2) Add tris(ethylmethylamino)chlorosilane and polyoxyethylene octylphenol ether OP-10 to water, heat to 60°C and stir for 15 minutes to obtain glue, in which tris(ethylmethylamino) The mass concentration of chlorosilane is 30%, and the mass concentration of dispersant is 15%.

[0028] (3) Coat the glue evenly on the pretreated fabric, the coating amount is 100g / m 2 , heating and curing, the temperature is 120 ° C, the time is 30 minutes, and a dense anti-fouling film is formed on the fabric.

[0029] (4) Use a calender to perform calendering treatment on the fabric formed with the anti-fouling film at a temperature of 115° C., a pressure of 10 MPa, and a vehicle speed of 25 m / min to obtain an anti-fouling fabric.

Embodiment 2

[0031] The difference between embodiment 2 and embodiment 1 is that the coating amount of glue solution is different.

[0032] (1) Soak 5 kg of pure cotton fabric in 50 kg of 1-butyl-3-methylimidazolium dicyandiamide salt solution with a mass concentration of 10%, heat to 80° C. for 1 hour, and dry to complete the pretreatment of the fabric.

[0033] (2) Add tris(ethylmethylamino)chlorosilane and polyoxyethylene octylphenol ether OP-10 to water, heat to 60°C and stir for 15 minutes to obtain glue, in which tris(ethylmethylamino) The mass concentration of chlorosilane is 30%, and the mass concentration of dispersant is 15%.

[0034] (3) Evenly coat the glue solution on the pretreated fabric, and the coating amount is 120g / m 2 , heating and curing, the temperature is 120 ° C, the time is 30 minutes, and a dense anti-fouling film is formed on the fabric.

[0035] (4) Use a calender to perform calendering treatment on the fabric formed with the anti-fouling film at a temperature...

Embodiment 3

[0037] The difference between embodiment 3 and embodiment 1 is that the mass concentration of tris(ethylmethylamino)chlorosilane in the glue is different.

[0038] (1) Soak 5 kg of pure cotton fabric in 50 kg of 1-butyl-3-methylimidazolium dicyandiamide salt solution with a mass concentration of 10%, heat to 80° C. for 1 hour, and dry to complete the pretreatment of the fabric.

[0039] (2) Add tris(ethylmethylamino)chlorosilane and polyoxyethylene octylphenol ether OP-10 to water, heat to 60°C and stir for 15 minutes to obtain glue, in which tris(ethylmethylamino) The mass concentration of chlorosilane is 35%, and the mass concentration of dispersant is 15%.

[0040] (3) Coat the glue evenly on the pretreated fabric, the coating amount is 100g / m 2 , heating and curing, the temperature is 120 ° C, the time is 30 minutes, and a dense anti-fouling film is formed on the fabric.

[0041] (4) Use a calender to perform calendering treatment on the fabric formed with the anti-fouli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com