Anti-rotating self-locking bone fracture internal fixing device

An internal fixator and anti-rotation technology, applied in the directions of internal fixator, fixator, internal bone synthesis, etc., can solve problems such as inapplicable fractures, and achieve the effect of clear effect, shortened operation time, and reliable anti-rotation effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

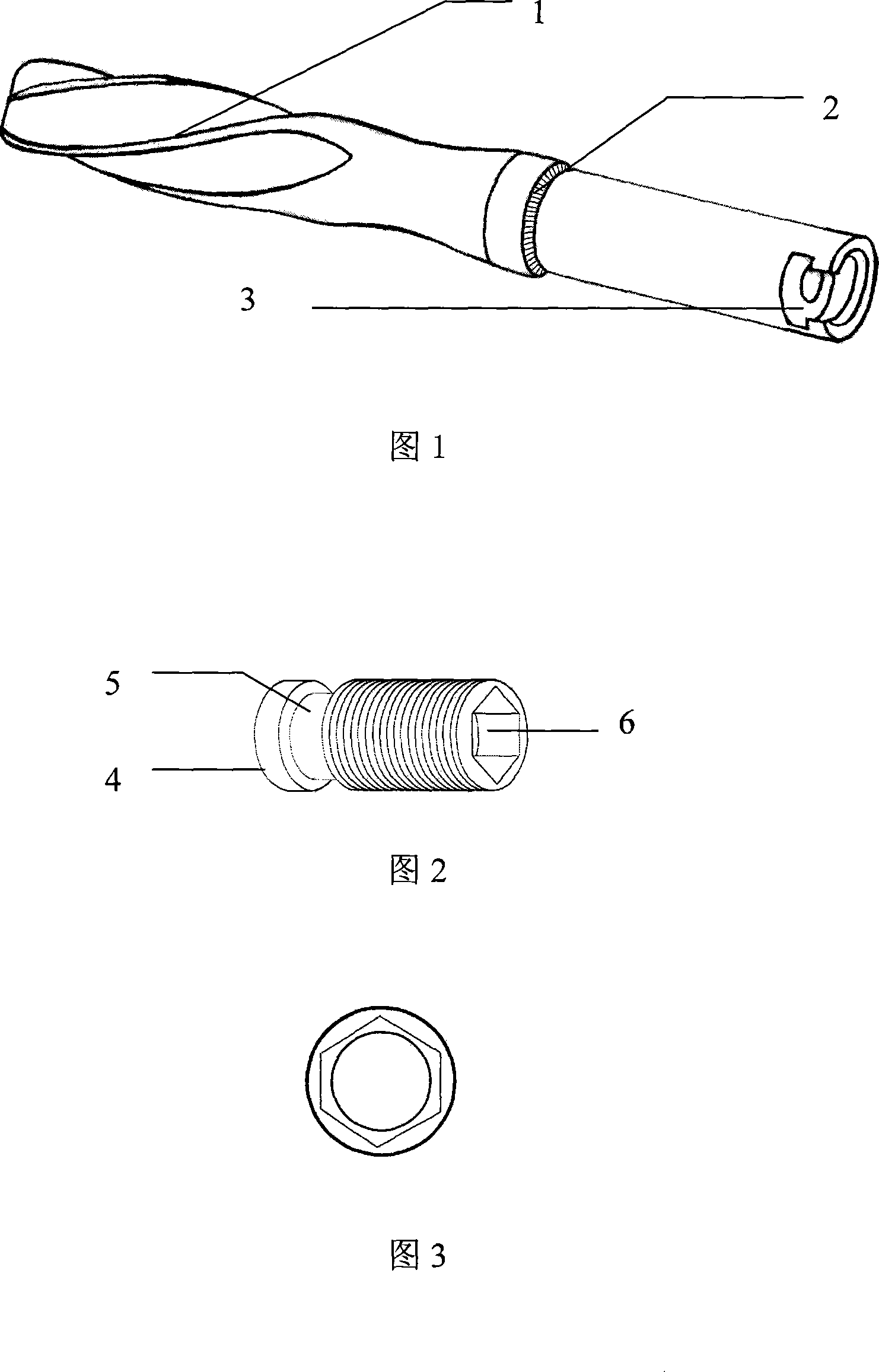

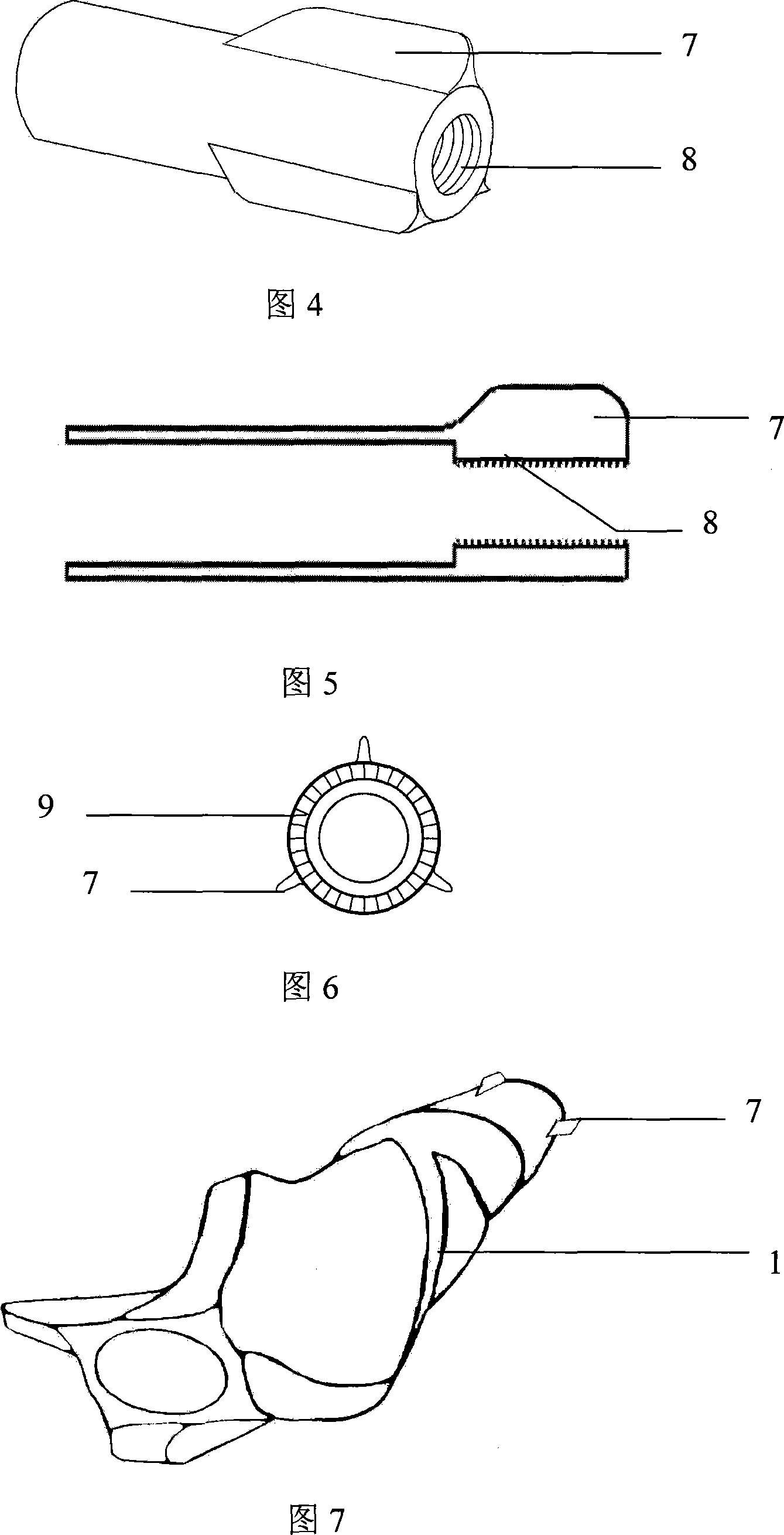

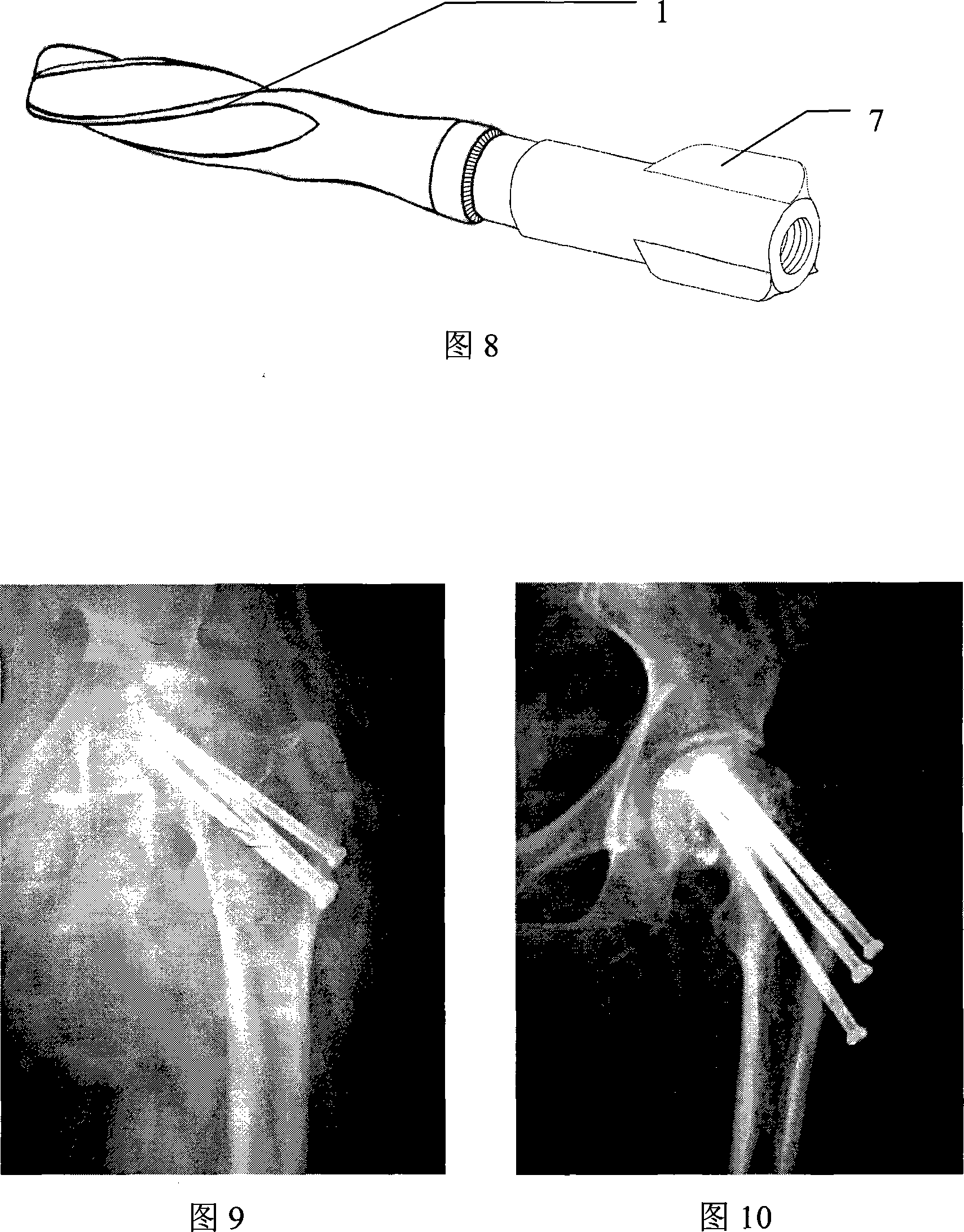

[0043] Example 1 The structure of the anti-rotation self-locking fracture internal fixator with tooth patterns on the back section of the screw rod and the end surface of the sleeve:

[0044] See attached drawings 1 to 8. The structure of the internal fixator for anti-rotation self-locking fractures consists of the screw rod shown in Fig. 1, the built-in connecting bolt shown in Fig. 2 and Fig. 3, and the three-winged internal fixator shown in Fig. It consists of a sleeve, and the three parts are hollow structures.

[0045] The screw part has three helical blades 1, which are used to drive into the femoral head. The head end of the blade is in the shape of a spiral cone to facilitate penetration into the cancellous bone. The linear length of the helical blade part is between 15mm and 30mm; The front part with the helical blade is thicker, and the middle part of the rear part of the screw is thinner, so as to occupy the smallest fracture area when driving into the femoral neck....

Embodiment 2

[0059] Example 2 An anti-rotation self-locking fracture internal fixator with tooth patterns on the end surface of the rear end of the screw rod and the inner surface of the sleeve

[0060] Except that the end surface of the rear section of the screw and the end surface of the sleeve do not have tooth lines, and the tooth lines are on the end surface of the end of the rear section of the screw rod and the inner surface of the sleeve, the rest of the structure is the same as that of Embodiment 1.

[0061] During the operation, the fixers in the unlocked state and locked state are shown in Fig. 11 and Fig. 12 respectively. Since the teeth are inside the sleeve, they are not shown in the figure.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Straight line length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com