Reversible cold rolling mill flow quantity AGC band thickness control method

A strip thickness and rolling mill technology, applied in the direction of rolling mill control device, material size control, non-electric variable control, etc., can solve the problems of no flow AGC, low output, etc., and achieve the effect of improving control accuracy and increasing yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

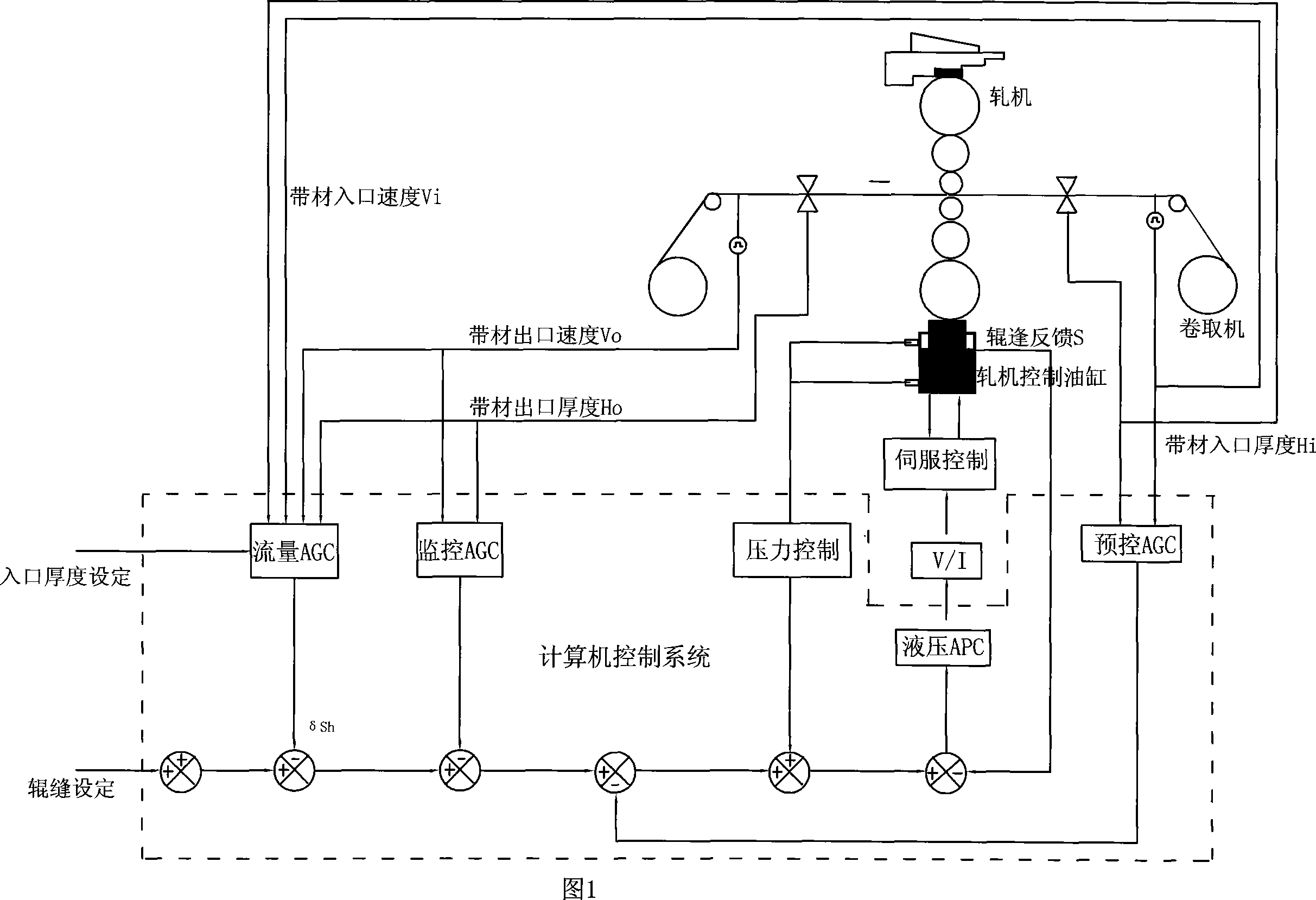

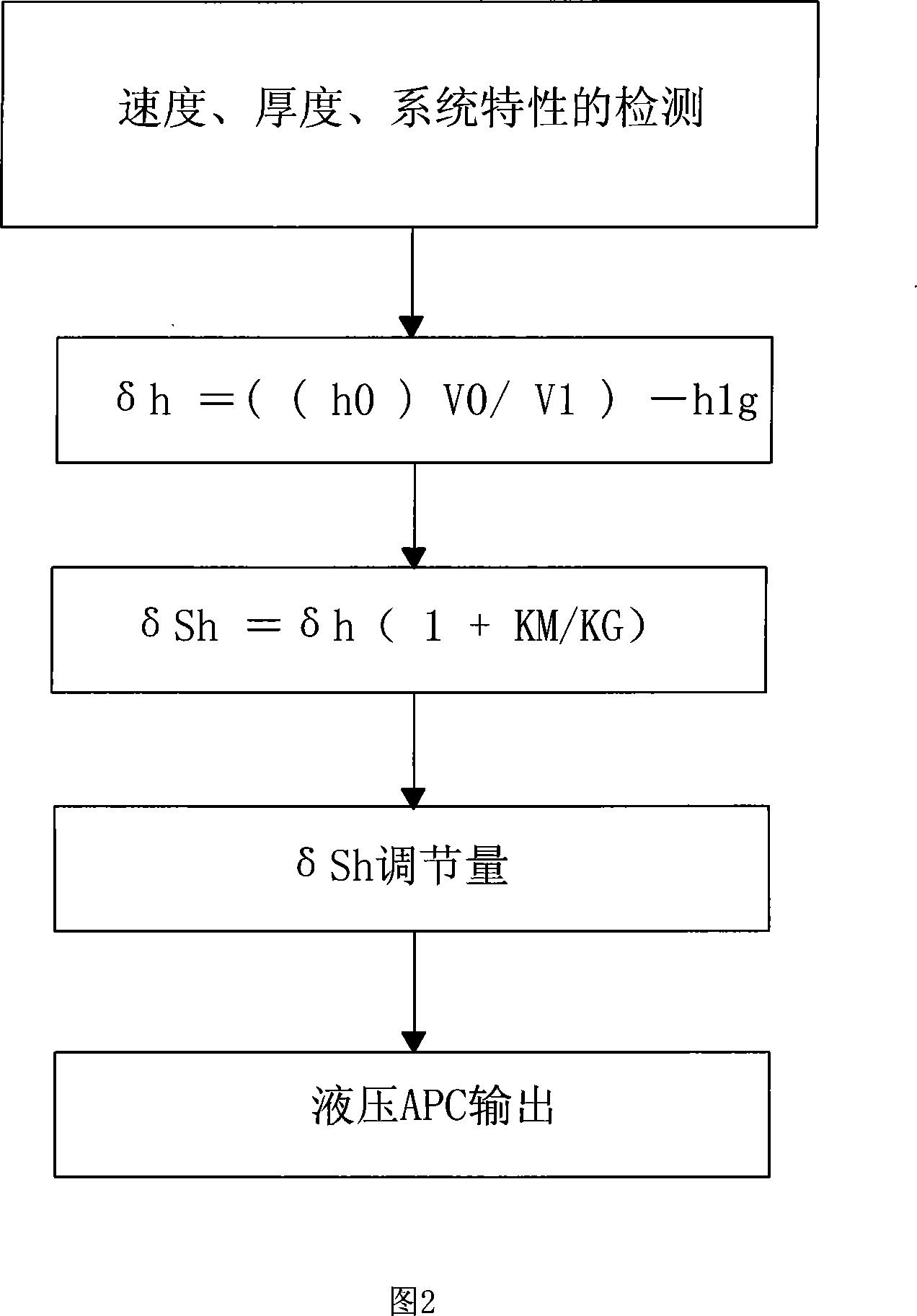

[0019] As shown in Figure 1 and Figure 2, the flow AGC thickness control function is an integral part of the hydraulic AGC rolling mill thickness automatic control system, and is an outer ring of the rolling mill roll gap thickness control. This control loop will detect and feed back the inlet thickness, speed, outlet speed, and thickness setting signals through the calculation of the flow AGC mathematical model equation to obtain the theoretical outlet thickness difference and the corresponding adjustment of the rolling mill roll gap deviation to be compensated, that is, δS h , this adjustment amount δS h Then, the output is adjusted by the inner ring of the hydraulic AGC (that is, the hydraulic APC), so that the servo cylinder of the rolling mill changes, and the roll gap and rolling pressure of the rolling mill also change accordingly according to the control amount requirements, thereby reducing the thickness deviation of the strip. achieved the purpose of control.

[002...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com