Automatic control system for white spirit blending

An automatic control system and liquor technology, applied in the field of liquor blending automatic control system, can solve the problems of only about 80% one-time success rate, low production efficiency, high labor intensity, etc., achieve high success rate, convenient production management, and operability strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Below in conjunction with the accompanying drawings and specific examples are described in further detail:

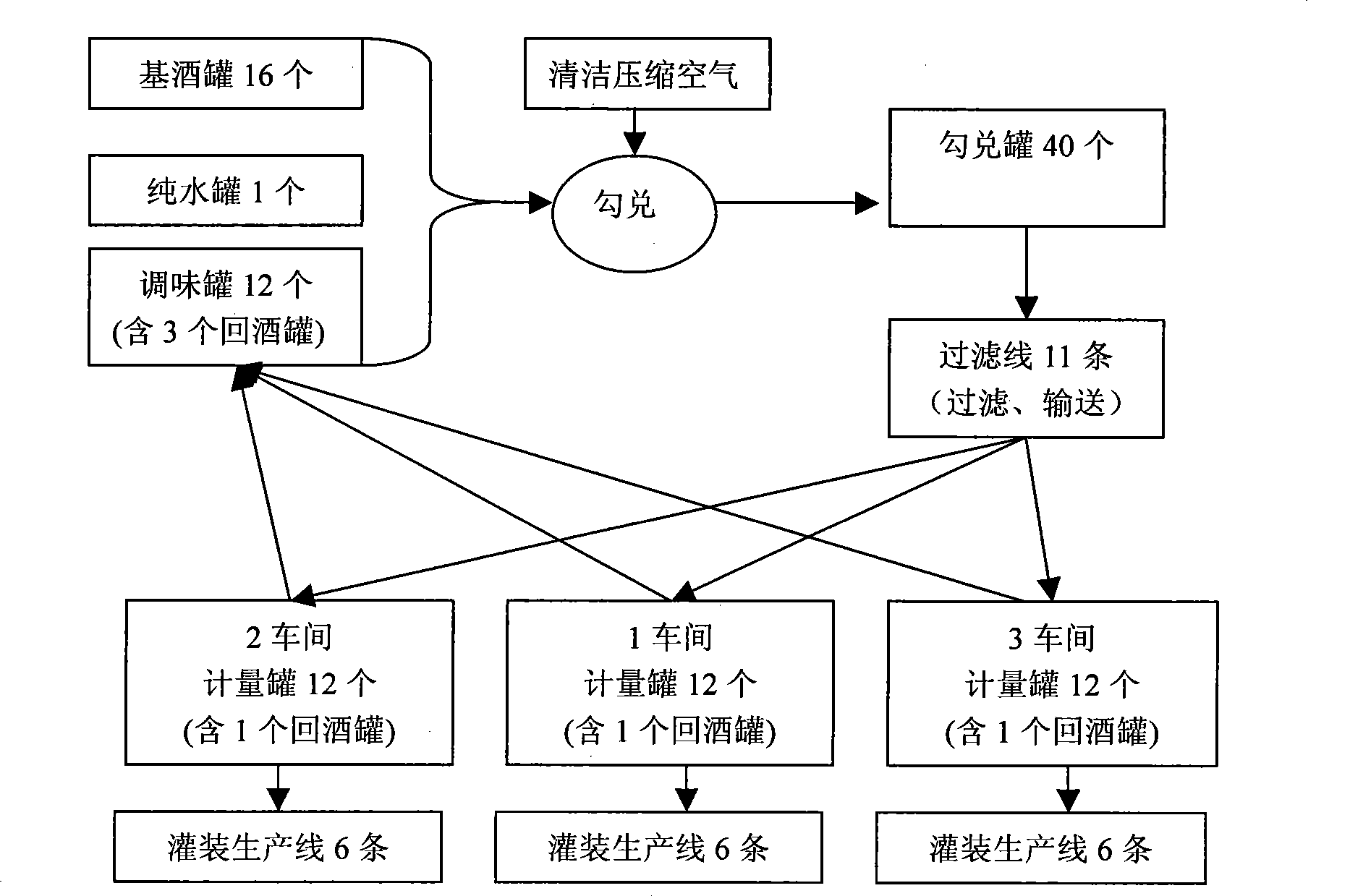

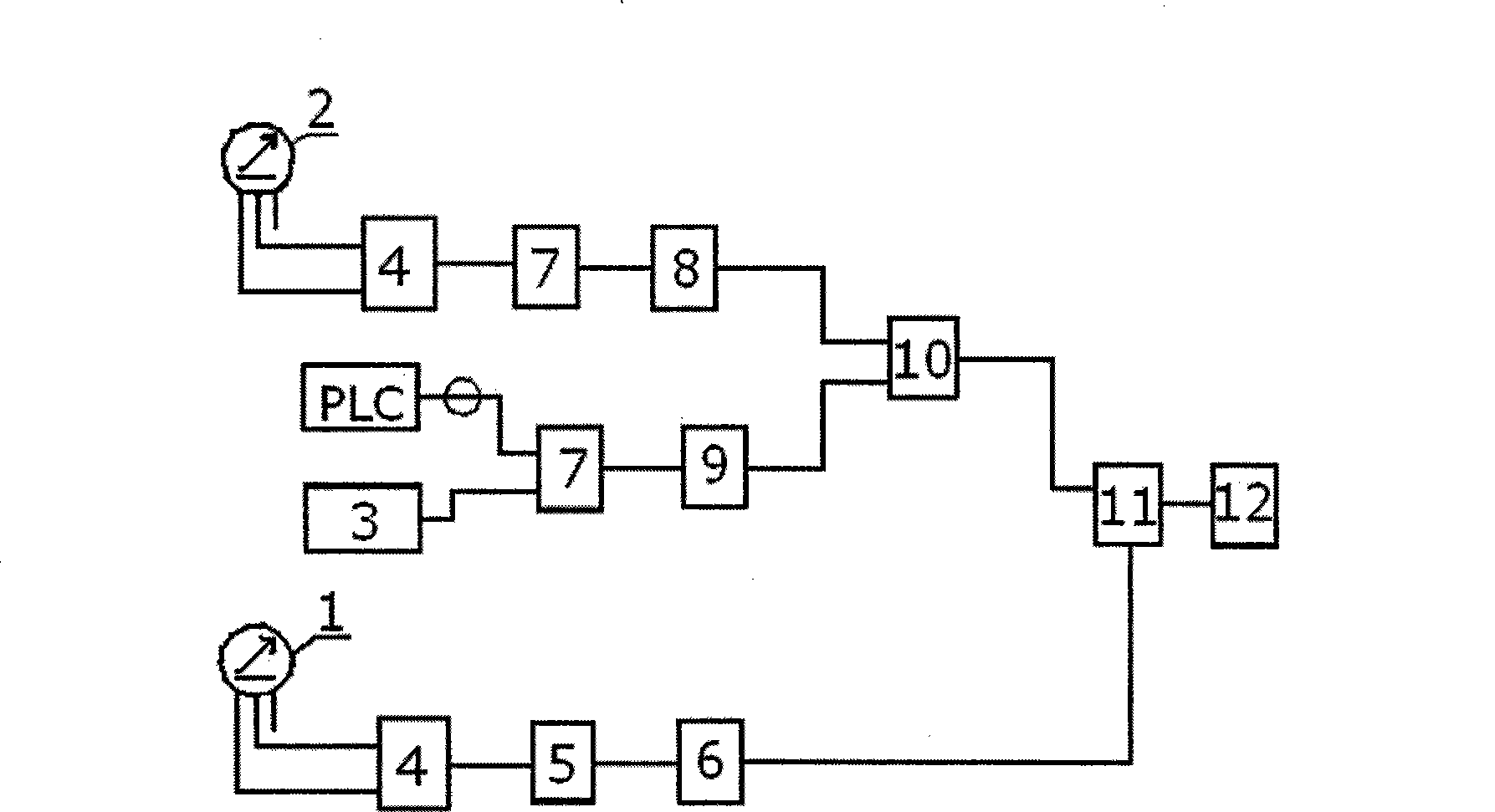

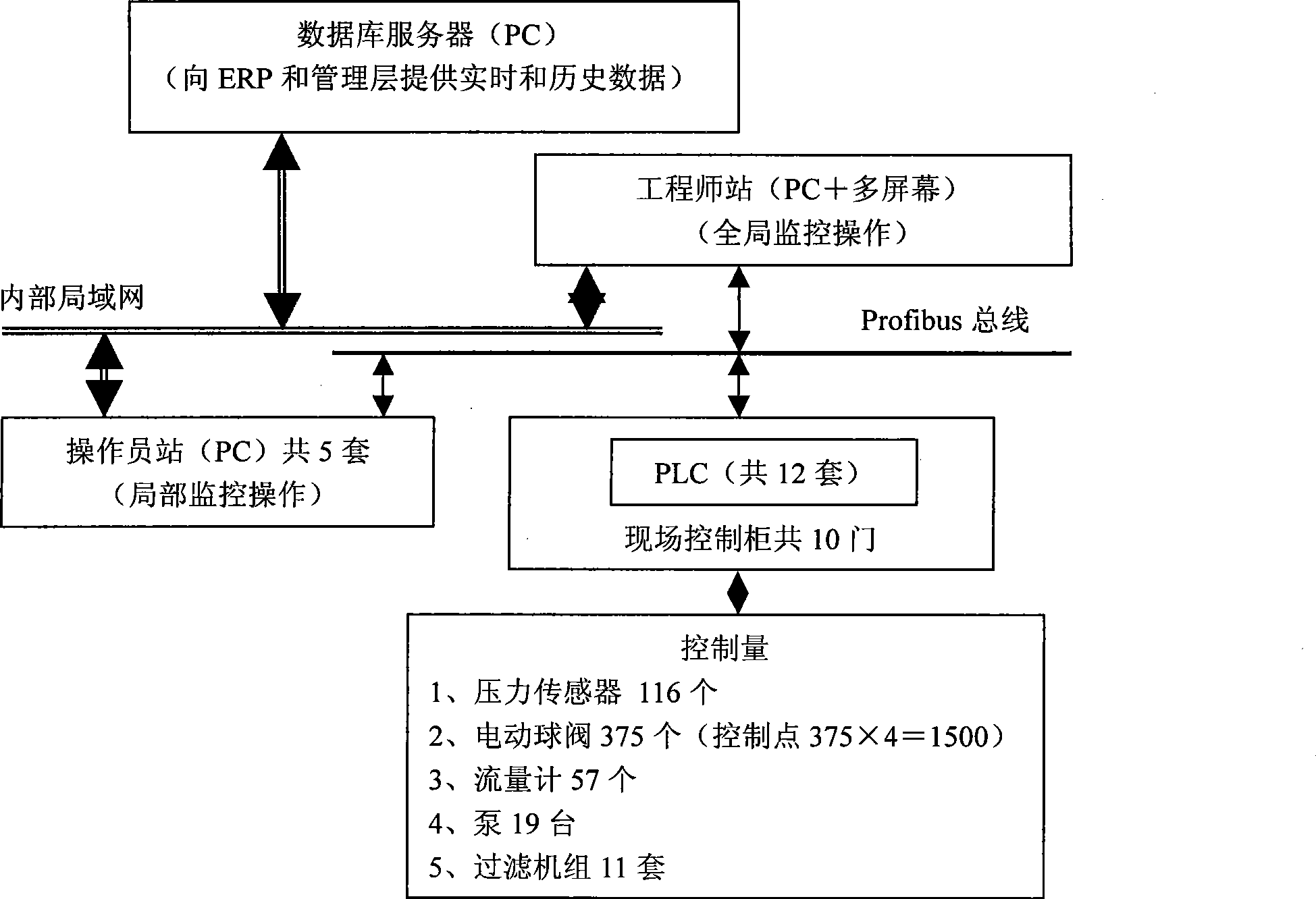

[0021]The liquor blending automatic control system of the invention includes a plurality of base wine tanks equipped with electric control valves, a plurality of seasoning wine tanks equipped with electric control valves, a pure water tank equipped with a conveying pump, and an air tank equipped with a compressed air purification device. Compressor, multiple blending tanks connected with finished wine tanks through filtering system, programmable controller PLC and industrial control computer; base wine tanks and seasoning wine tanks are respectively connected with conveying pumps, flow meters, electric control valves and base wine conveying pipelines Connect the blending tank equipped with the electric control valve, the pure water tank is connected to the blending tank equipped with the electric control valve through the conveying pump, flow meter, electric contr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com