Upright quenching furnace

A quenching furnace, vertical technology, applied in the direction of quenching device, furnace, furnace type, etc., can solve the problems of uneven heating temperature of aluminum alloy, affect the performance of aluminum alloy, and occupy large space for equipment, so as to shorten the quenching transfer time, improve the Performance, small footprint effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

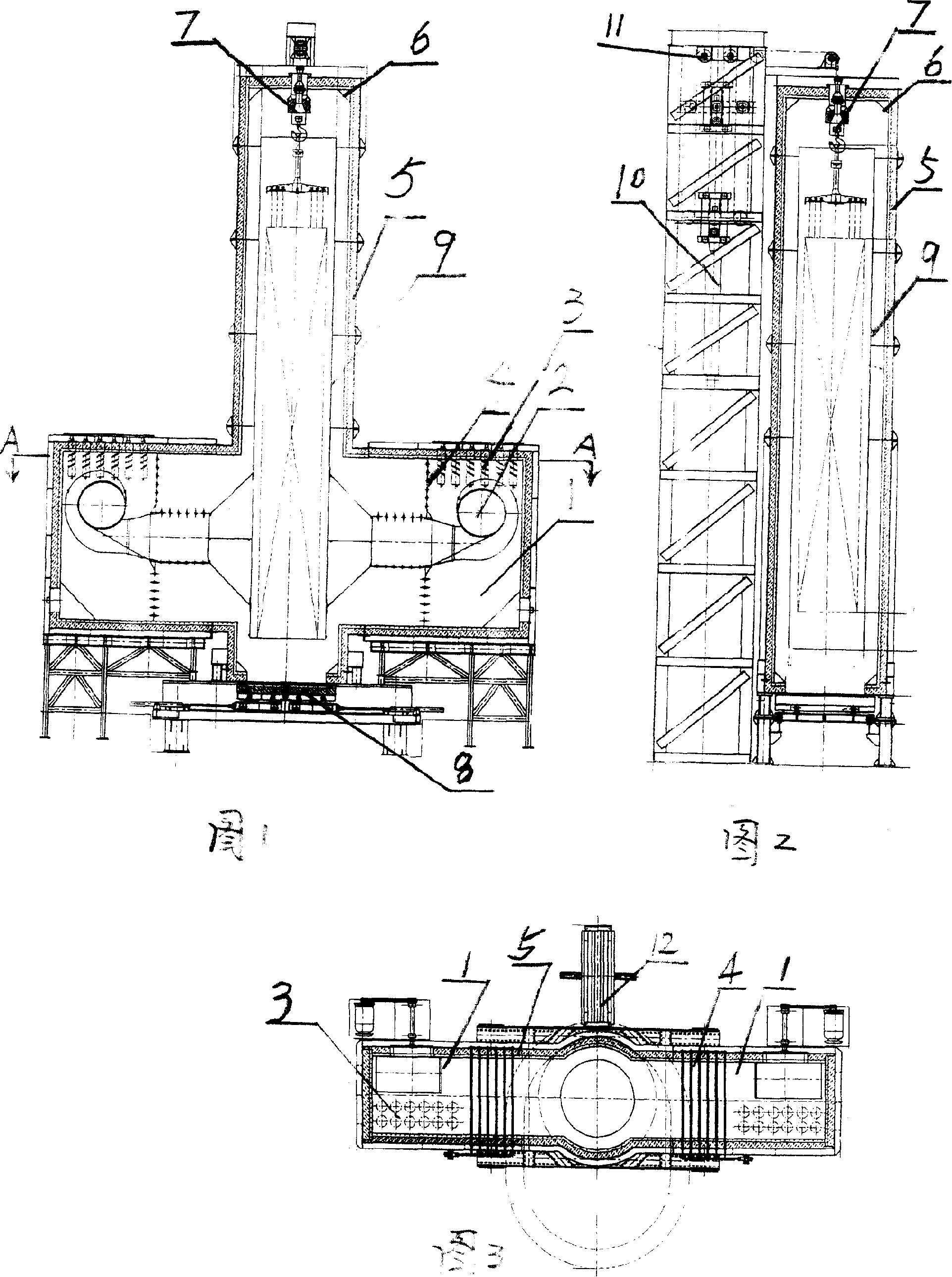

[0013] Refer to Figure 1-Figure 3. A vertical quenching furnace is composed of a cylindrical furnace body 5 with a fan chamber 1 symmetrically on both sides; a hydraulically driven furnace door 8 is provided at the lower end of the furnace body 5, and a hydraulic lifting device 12 is provided on one side of the furnace body 5. The material hook 7 of the hydraulic lifting device 12 is placed in the furnace body from the top of the furnace body, and the inner wall of the furnace body 5 is provided with a number of tie rods to fix the deflector 9; the fan chamber 1 is provided with a circulating fan 2. The structure of the electric heating 3, a guide device 4 is arranged between the fan chamber 1 and the furnace chamber. The flow device 4 is composed of multiple sets of flap valves. The top and bottom of the furnace body 5 are provided with curved baffles 6. The hydraulic lifting device is composed of a hydraulic cylinder 10 supported by a bracket and a pulley block 11; the piston ro...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap