Ladle bottom construction method

A masonry and steel ladle technology, which is applied in the direction of construction, building structure, and building material processing, can solve the problems of excessive flatness of the bottom of the ladle, increased consumption of refractory materials, and rising costs, so as to reduce production costs, increase service life, Effect of cost reduction per ton of steel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

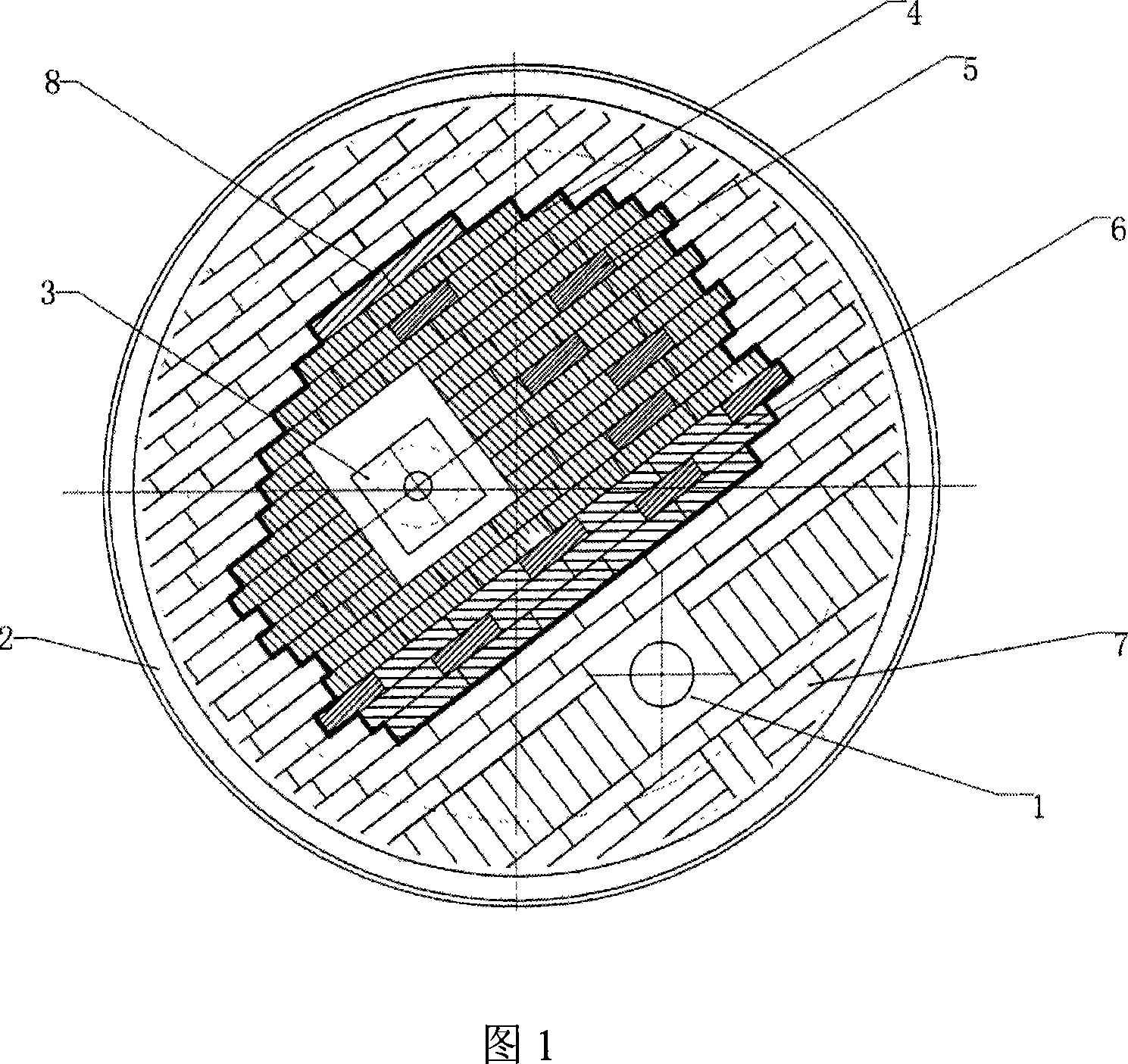

[0013] The masonry method example at the bottom of the ladle of the present invention is:

[0014] 1) The bottom of the masonry ladle starts from nozzle 1, and bricks 7 with a height of 180 mm, a length of 300 mm, and a thickness of 80 mm are used to build the area of the nozzle and the ladle wall 2.

[0015] 2) Two rows of bricks 7, three rows of bricks 6 with a height of 240 mm, a length of 300 mm, and a thickness of 80 mm, and two rows of bricks 4 with a height of 300 mm, a length of 300 mm, and a thickness of 80 mm are successively built between the nozzle 1 and the ventilation brick 3. On the 2nd row of bricks 7, build 1 high 350mm by masonry respectively along the both sides of the square brick center line of the nozzle, long 300mm, the brick 5 of thick 80mm. In the middle of the first row of bricks 6, a block of bricks 7 is built, and in the second and third rows, a block of bricks 5 is built every two blocks.

[0016] 3) The tank bottom impact area is built with bri...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com