Duplex high precision temperature controller

A temperature controller and temperature control technology, which is applied in the direction of using electric mode for temperature control, etc., can solve the problems of inability to meet the control accuracy requirements, large size, and high cost, and achieve the effect of high-precision acquisition.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in further detail below in conjunction with accompanying drawings and examples.

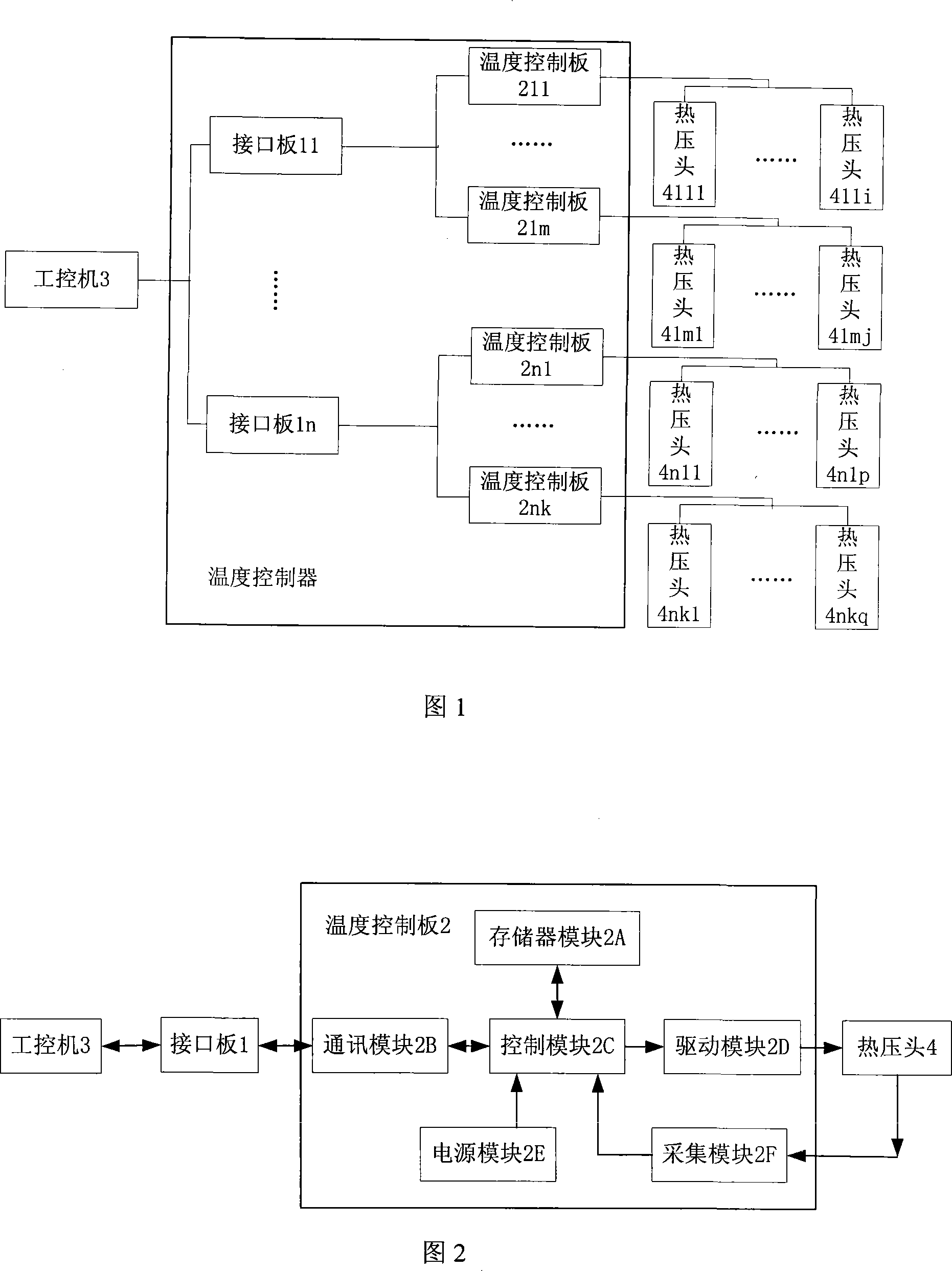

[0022] The temperature controller of the present invention includes two parts: an interface board and a temperature control board. The interface board can be expanded to 32 at most, and each interface board can be connected to 1 to 8 temperature control boards, and each temperature control board can control 1 to 8 temperature control boards. Thermal head. As shown in Figure 1, interface board 11 is connected with temperature control board 211,..., 21m,..., interface board 1n,..., 1n is connected with temperature control board 2n1,..., 2nk; The board 211 is connected to the thermal pressing heads 4111, ..., 411i, ..., the temperature control board 21m is connected to the thermal pressing heads 41m1, ..., 41mj, ..., the temperature control board 2n1 is connected to the thermal pressing heads 4n11, ..., 4n1p connection, ..., the temperature control boa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com