Mg-based ferrite, an electrophotographic development carrier containing the ferrite, and developer containing the carrier

A magnesium-based ferrite, electrophotography technology, applied in the direction of developer, electrical recording, optics, etc., can solve the problem of low saturation magnetization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

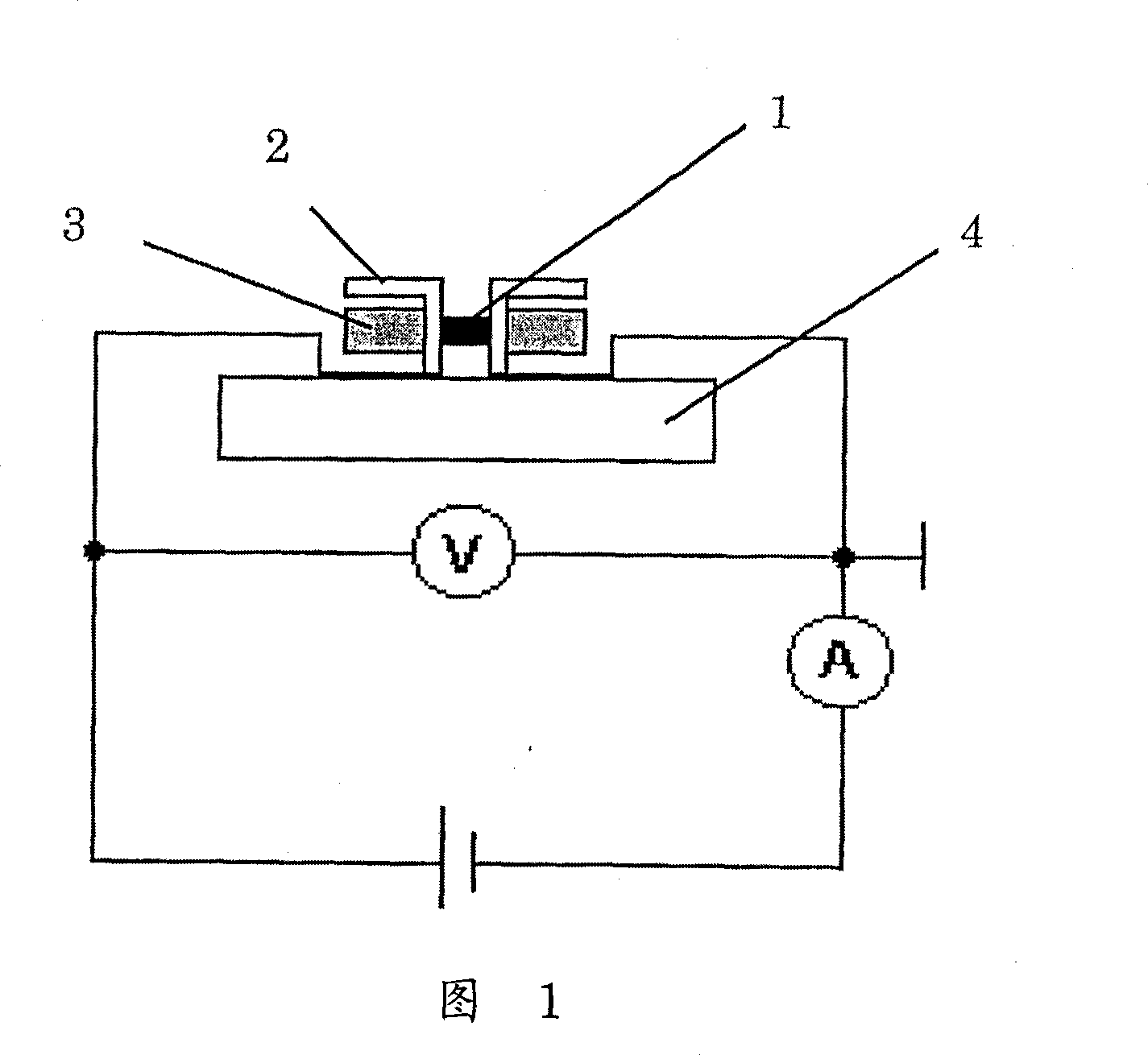

Image

Examples

preparation example Construction

[0081] The preparation process of the present invention includes the step i) of mixing raw materials and at least two heating steps: step ii) sintering the mixed raw materials under an inert atmosphere to grow particles, and step iii) heating the sintered raw materials in an oxygen-containing atmosphere to control And adjust its properties such as oxidation number of each metal, crystal structure, occupancy of each site and magnetic structure well. By adjusting the conditions of the sintering and heating steps, such as oxygen concentration, sintering temperature, sintering cycle, heat treatment temperature, and heat treatment period, it is possible to obtain the desired properties of the magnetic carrier, including dielectric breakdown voltage and saturation magnetization. For example, the desired support properties can be obtained by performing step iii) in an atmosphere of higher oxygen concentration than in step ii) and setting the maximum temperature of step ii) higher than...

Embodiment 1 to 27

[0098] Use MgO, Fe as shown in Table 1 2 o 3 , CaO and additives as raw materials to prepare magnesium-based ferrite materials. First, raw materials were weighed to obtain predetermined compositions as listed in Table 1. Then weighed raw materials were added to water together with binder (polyvinyl alcohol), dispersant and defoamer; ground and mixed in a wet ball mill for 4 hours to prepare a slurry. The concentration of the slurry was 50 wt%. Based on the total amount of raw materials in the slurry, the amount of the defoamer is 0.1 wt%, and the amount of the dispersant is 0.15 wt%.

[0099] The obtained slurry was dried and granulated by a spray dryer to prepare spherical granules. These spherical pellets were sintered in an electric furnace at 1200°C in a nitrogen atmosphere. The oxygen concentration in the nitrogen atmosphere is 1000 ppm or less. The sintered material was heated at 500°C in a nitrogen atmosphere having an oxygen concentration of 20 vol%. Then, the m...

Embodiment 28

[0121] Preparation of magnesium-based ferrite materials:

[0122] Using MgO, Fe 2 o 3 , CaO and the additives described in Table 3 to manufacture magnesium-based ferrite materials. First, these raw materials were weighed to obtain predetermined compositions as listed in Table 3. The weighed raw materials were added to water together with a binder (polyvinyl alcohol), a dispersant and an antifoaming agent; and ground and mixed in a wet ball mill for 4 hours to prepare a slurry. The concentration of the slurry was 50 wt%. Based on the total amount of raw materials in the slurry, the amount of the defoamer is 0.1 wt%, and the amount of the dispersant is 0.15 wt%.

[0123] The obtained slurry was dried and granulated by a spray dryer to prepare spherical granules. These spherical pellets were sintered in an electric furnace at 1300° C. under a nitrogen atmosphere. The oxygen concentration in this nitrogen atmosphere is 1000 ppm or less. The sintered material was heated at 4...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com