FC-SC, FC-SC-APC optical fiber connector

A FC-SC-APC and FC-SC technology, applied in the direction of light guides, optics, optical components, etc., can solve the problems of simple, convenient, reliable, low-cost connections, and no corresponding products for connectors, etc., to achieve reliable bonding The effect of combining, improving surface quality and reducing the cost of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

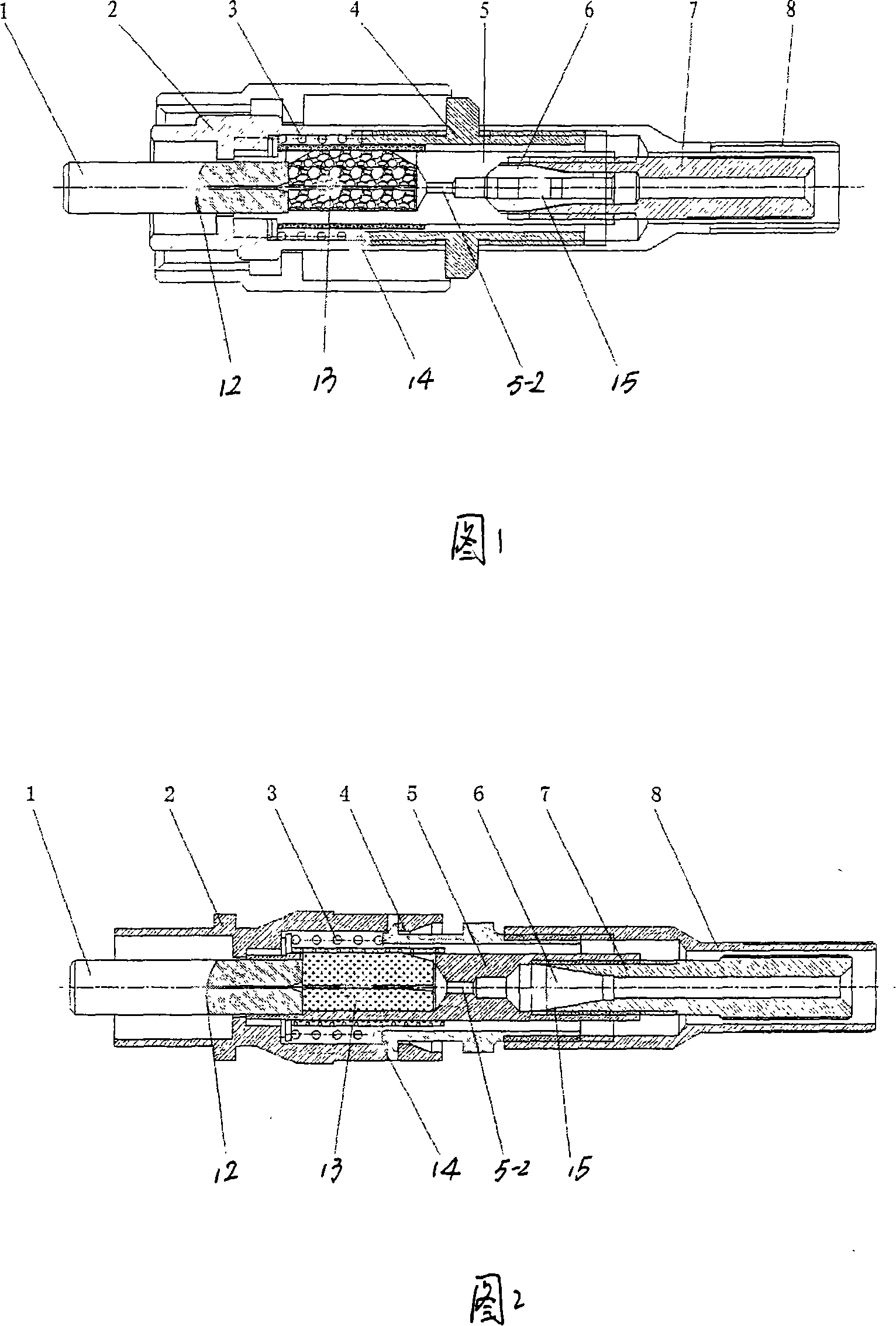

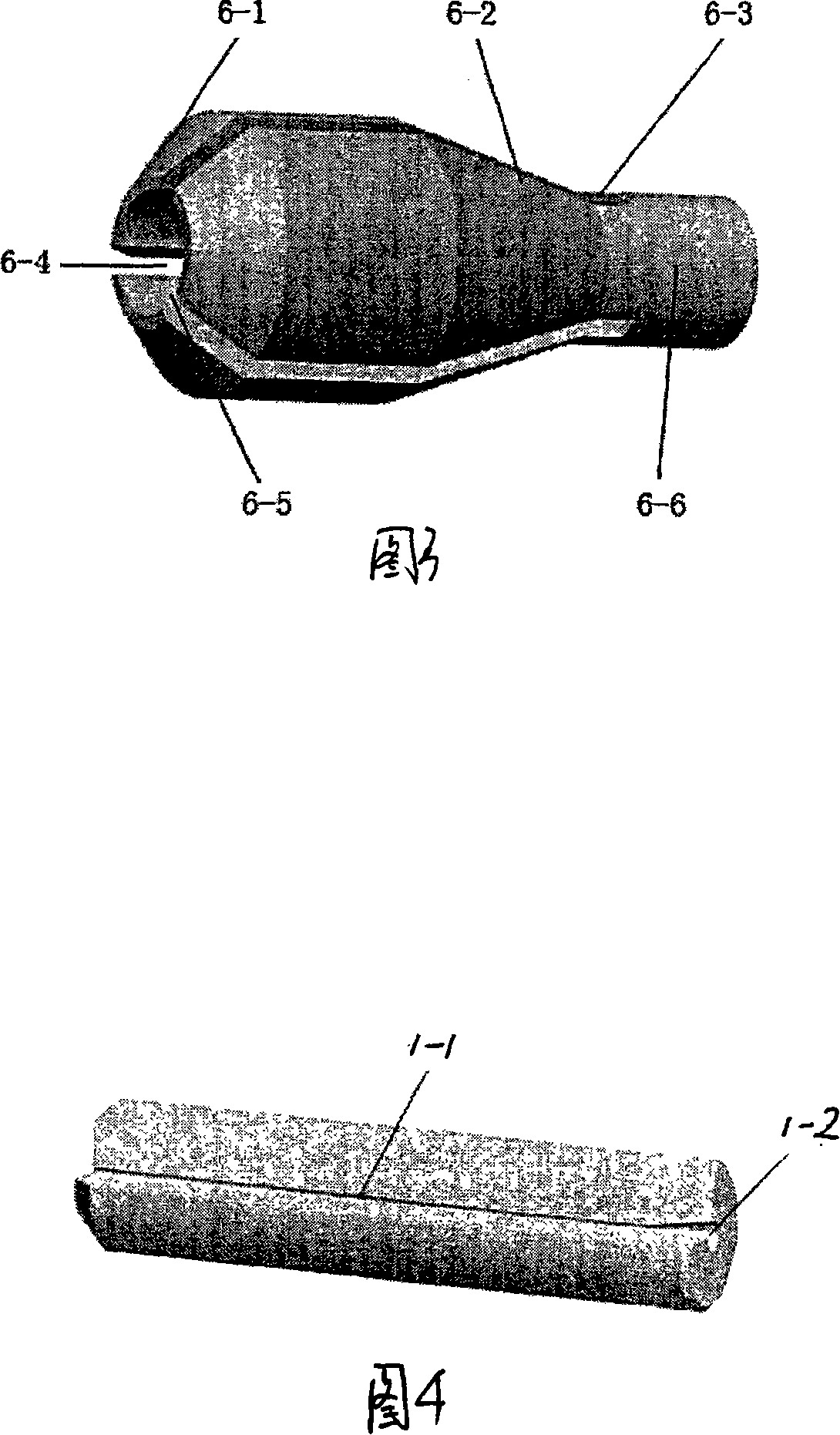

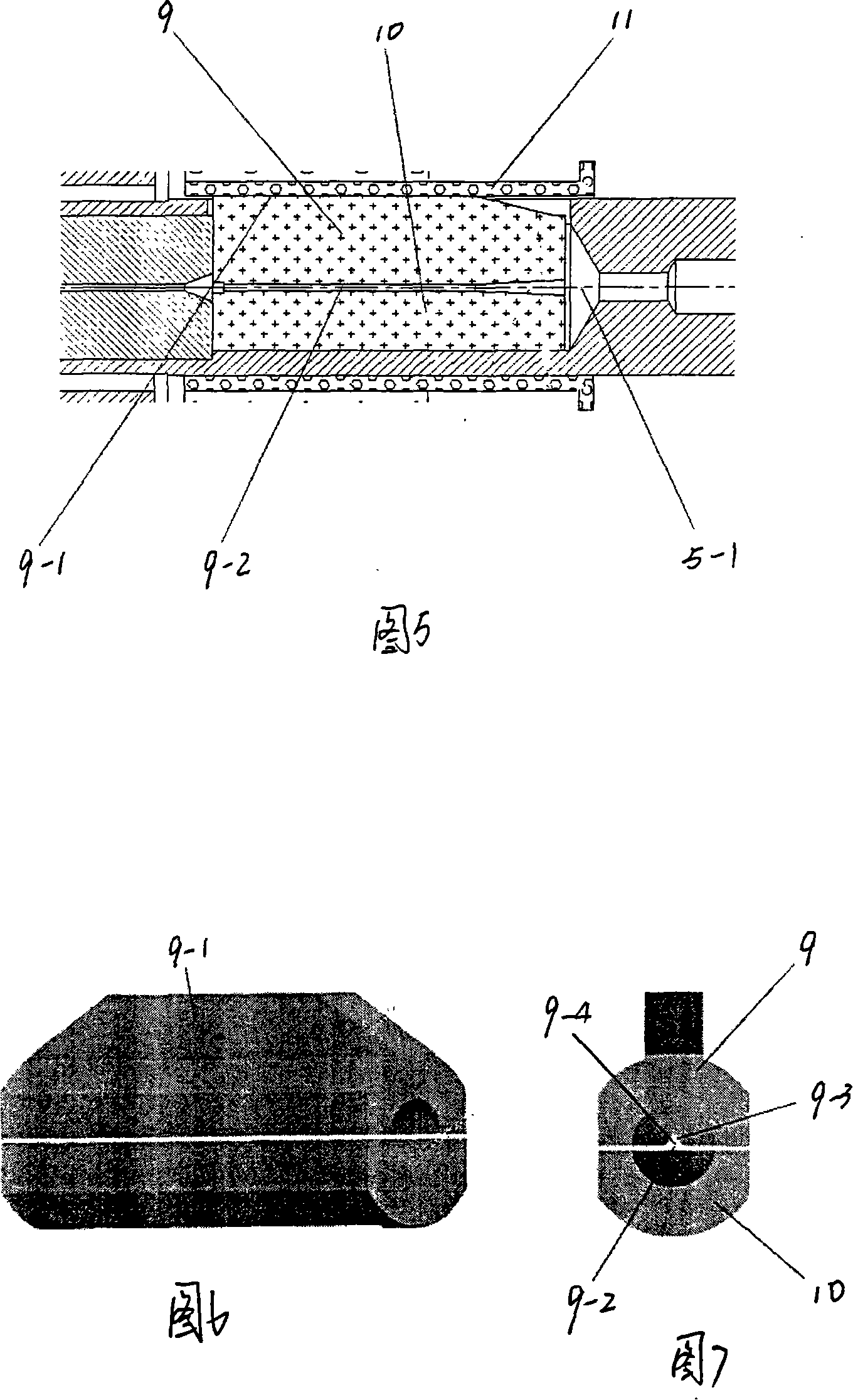

[0026] As shown in Figure 1-13, a quick connector sub-body is installed in the thrust device 14 to form a quick connector for optical fiber. The thrust device 14 is composed of a spring 3, an FC or SC housing 2, a spring connection seat 4, and a tail shell 8. The quick connector The sub-body is compressed in the SC plastic inner shell 2 by the spring 3 through the spring connection seat 4, and the tail case 8 is installed on the tail end of the spring connection seat to be packaged as a whole; 13 and a locking device 15, wherein the guiding and positioning device 12 is composed of a pin 1 and a pin seat sleeve 5, and the pin 1 is fixed in the pin seat sleeve 5 to form a guiding and positioning device 12, and the pin 1 has Precise and fine guide positioning hole 1-1, the front end of pin seat sleeve 5 is provided with a compression device accommodation cavity 5-1, the middle part of pin seat sleeve 5 has an optical fiber through hole 5-2, and the tail end of pin seat sleeve 5 ha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com