Steamship generator with rotor free cooling and stator evaporation cooling

A steam turbine generator and evaporative cooling technology, which is applied in cooling/ventilation devices, electrical components, electromechanical devices, etc., can solve the problems of complex manufacturing technology and high sealing requirements, and achieve the advantages of less auxiliary equipment, high unit efficiency and simple structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

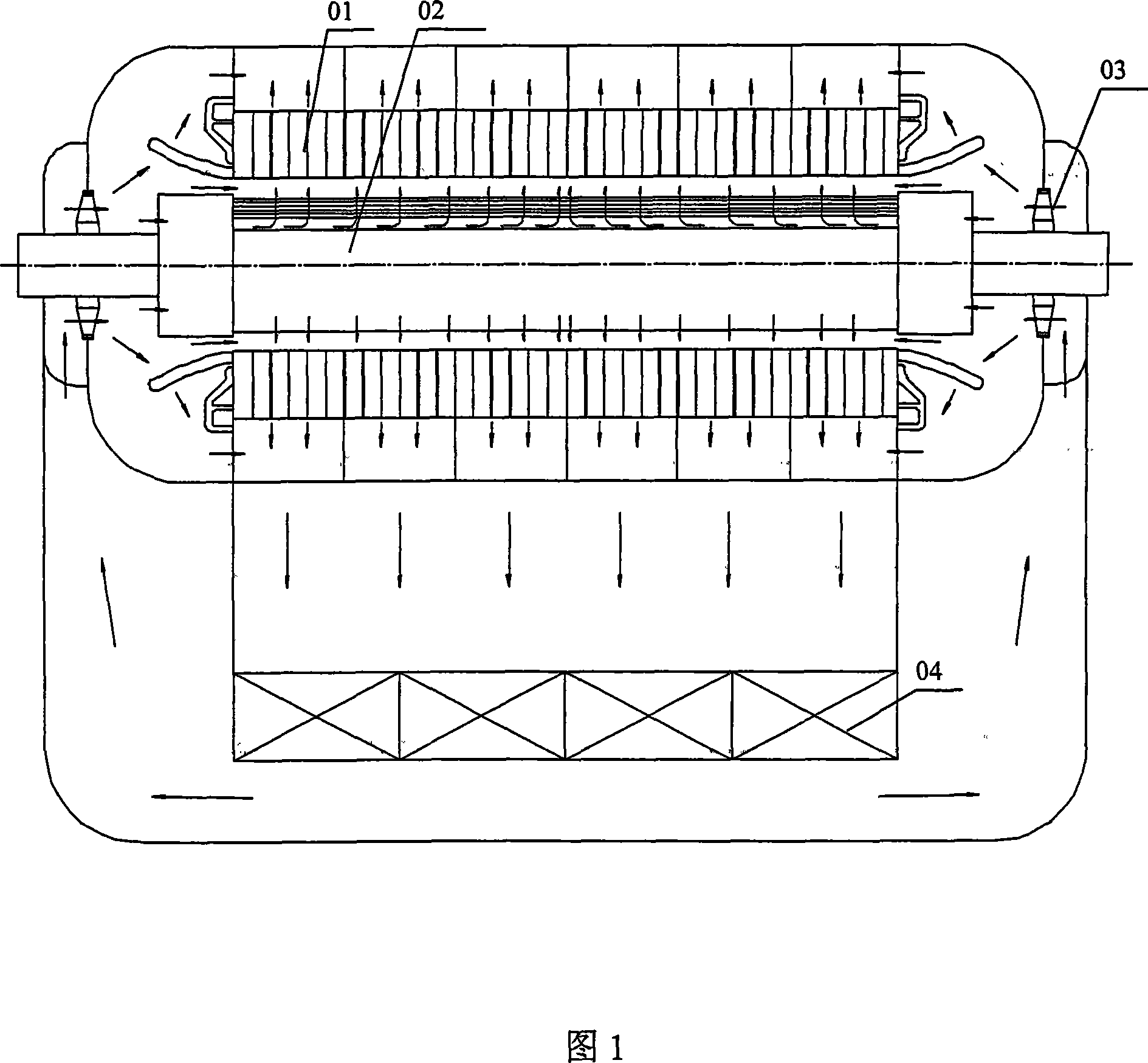

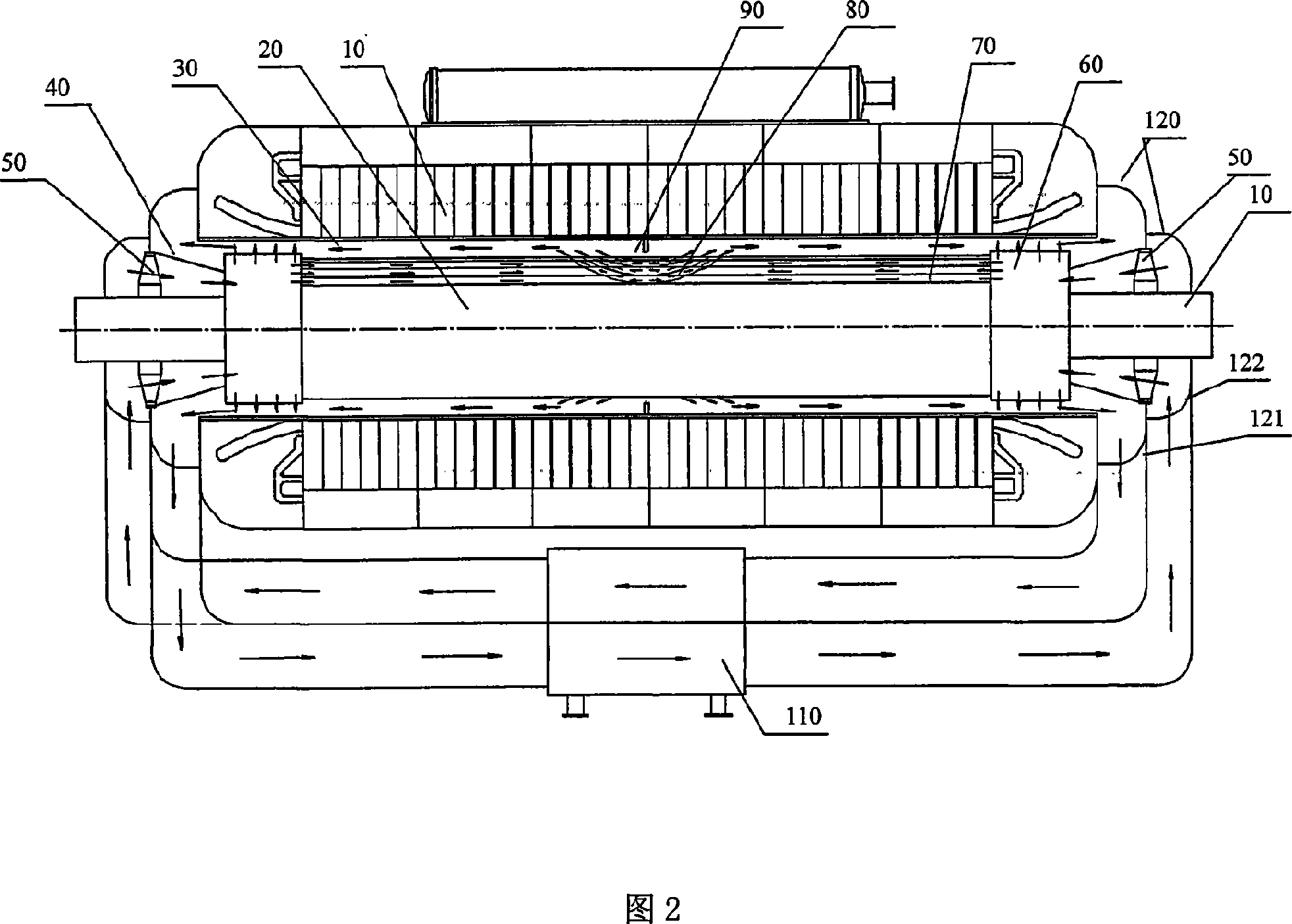

[0027] As shown in FIG. 2 , the present invention mainly includes an evaporatively cooled turbogenerator stator 10 and an air cooled turbogenerator rotor 20 . The stator 10 of the turbogenerator adopts a full-immersion evaporative cooling system, or an evaporative cooling system combining stator core immersion and forced circulation cooling in the winding. The inner wall of the stator 10 is separated from the rotor 20 by an isolation sleeve 30 , and an air gap is formed between the inner surface of the isolation sleeve 30 and the outer surface of the rotor 20 . The rotor 20 of the turbogenerator adopts the air cooling method of axial ventilation.

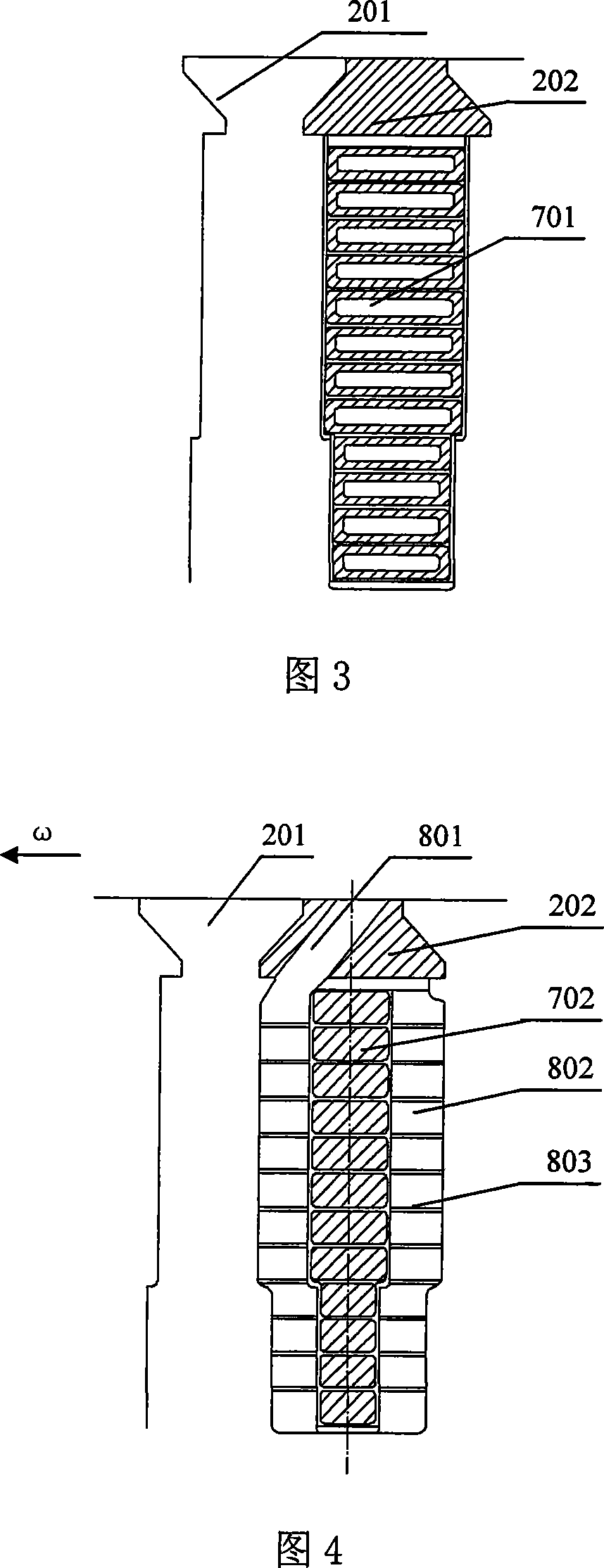

[0028] Fans 50 are provided at both ends of the rotor, and the outlet side of the fan 50 is directly connected to the air guiding ring 40 . The other side of the air guide ring 40 is connected to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com