Large-sized multiple layer coal fines furnace steam temperature control method

A technology of steam temperature and control method, which is applied in the direction of steam generation, control system, lighting and heating equipment, etc. It can solve the problems of large steam temperature control inertia, low unit efficiency, and complex system, so as to reduce the flow rate of desuperheating water and improve efficiency , Improving the effect of load response ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

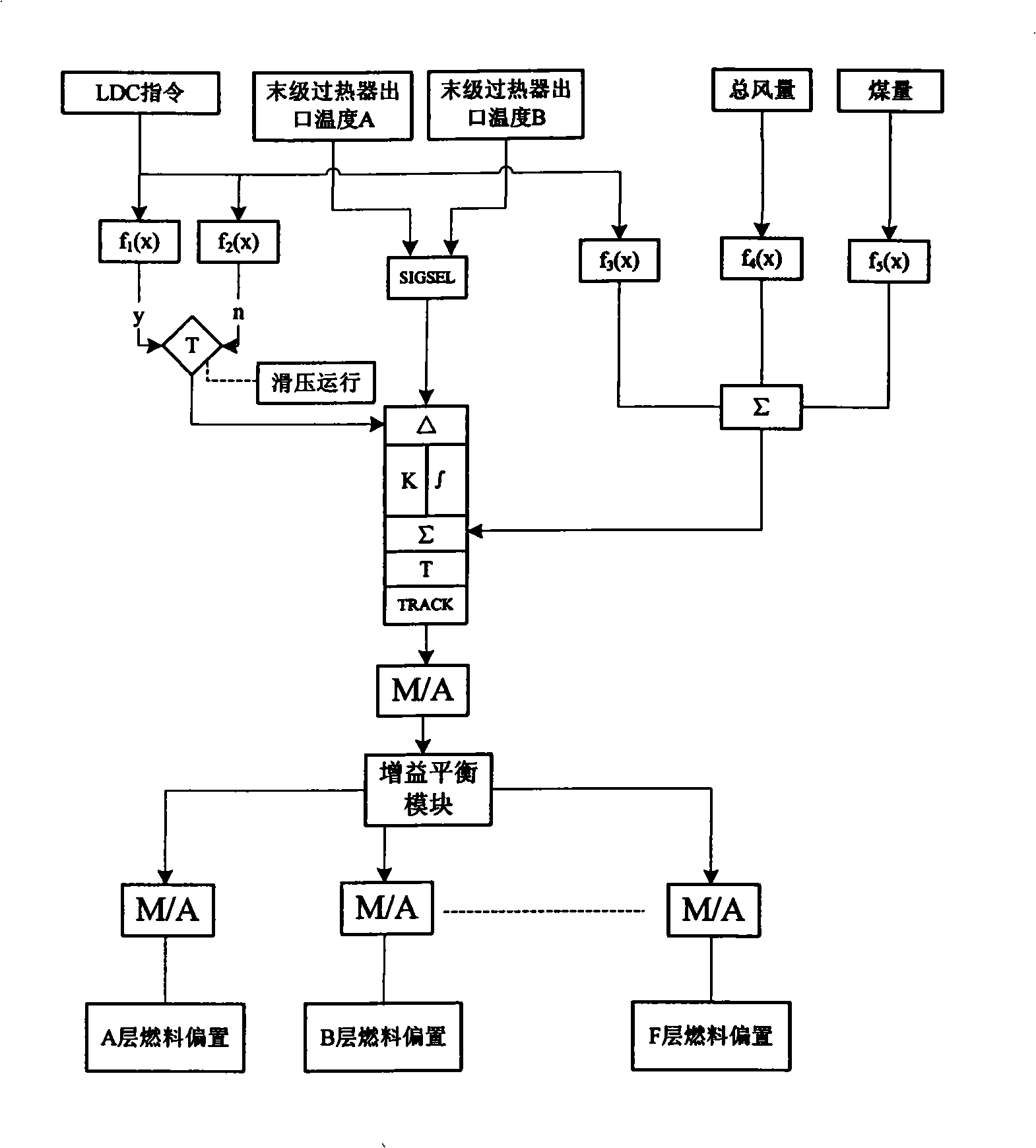

[0018] The method for controlling the steam temperature of a large-scale multi-layer pulverized coal boiler according to the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

[0019] Taking a 300MW unit as an example, the pulverizing system is a direct blowing type, using a medium-speed roller coal mill, and the five-layer burners A, B, C, D, and E are arranged in sequence from bottom to top.

[0020] Generally, the A layer is maintained manually for stable combustion, and the E layer powder is only used when other coal mills fail. Even if it is running, it is rarely operated in an automatic way, so the system can be simplified to a 3-layer fuel regulator.

[0021] The first step, control schematic configuration.

[0022] On the basis of the original combustion control system, the corresponding control logic is added. And complete the corresponding static test to ensure that the logic is correct and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com