EL key device and its making method

A technology of electroluminescence and manufacturing method, applied in electroluminescence light sources, electric light sources, lighting devices, etc., can solve the problems of uneven luminous brightness, uneven current distribution, poor circuit conduction, etc., and achieve uniform current distribution and cost. More, lower cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

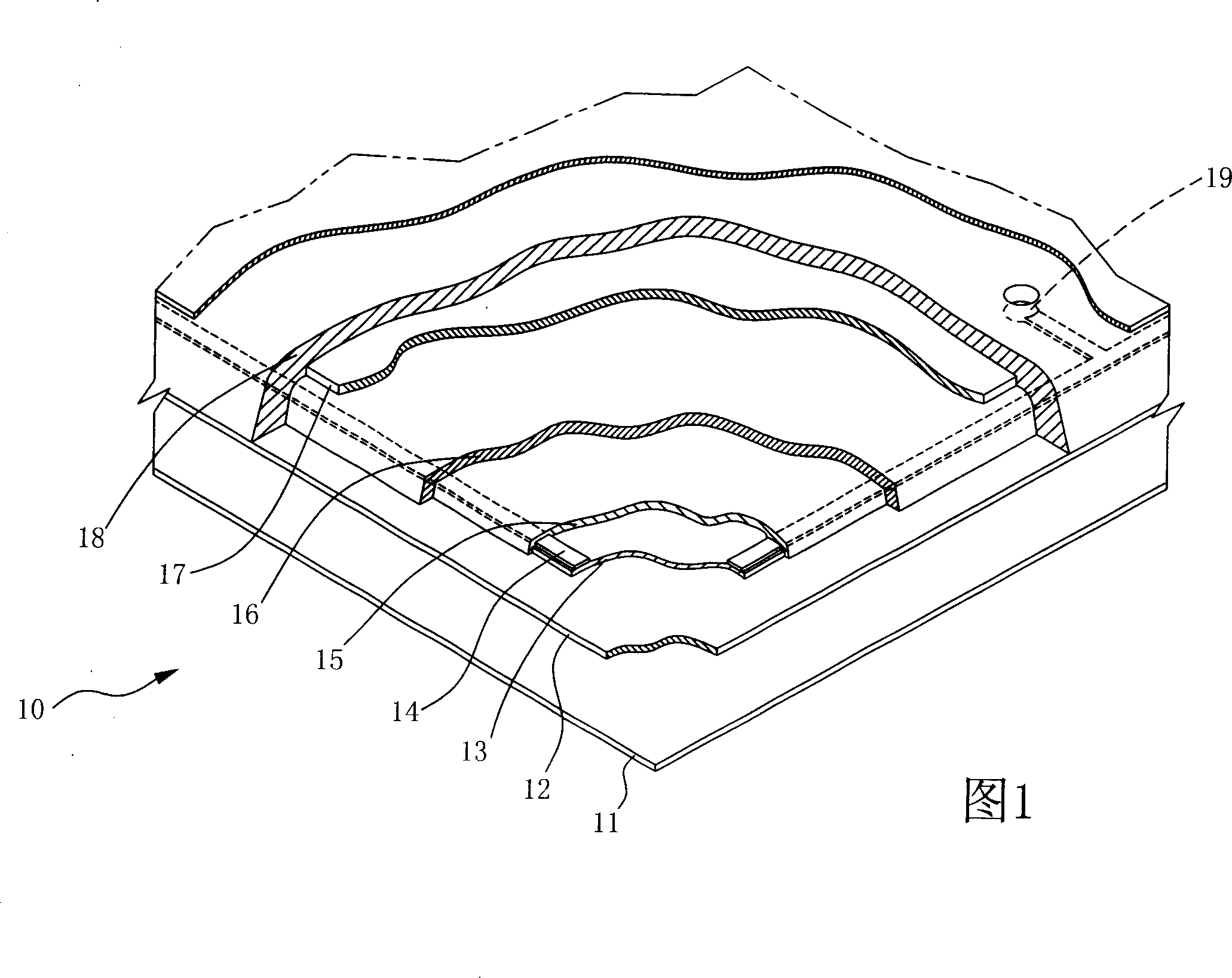

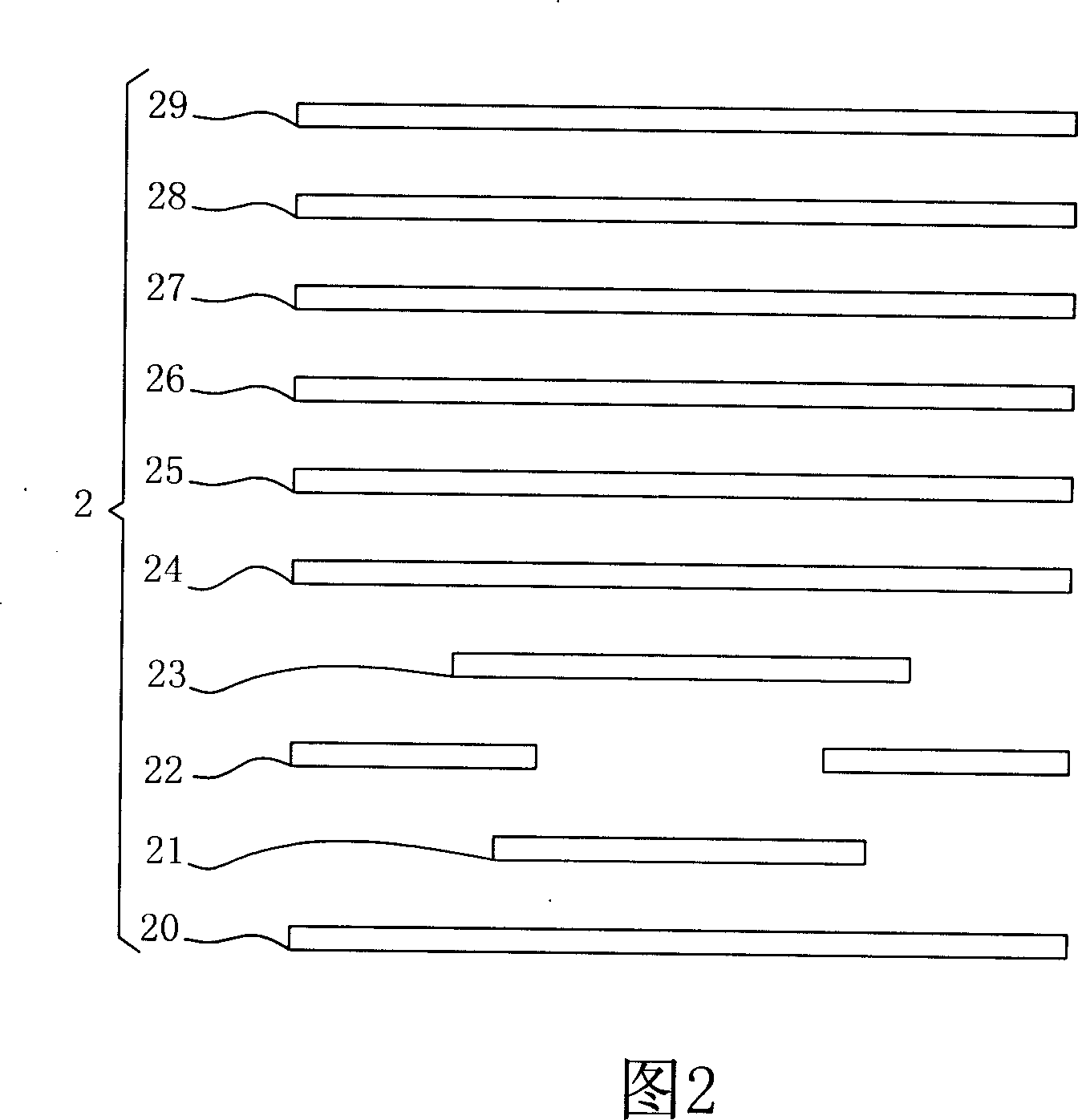

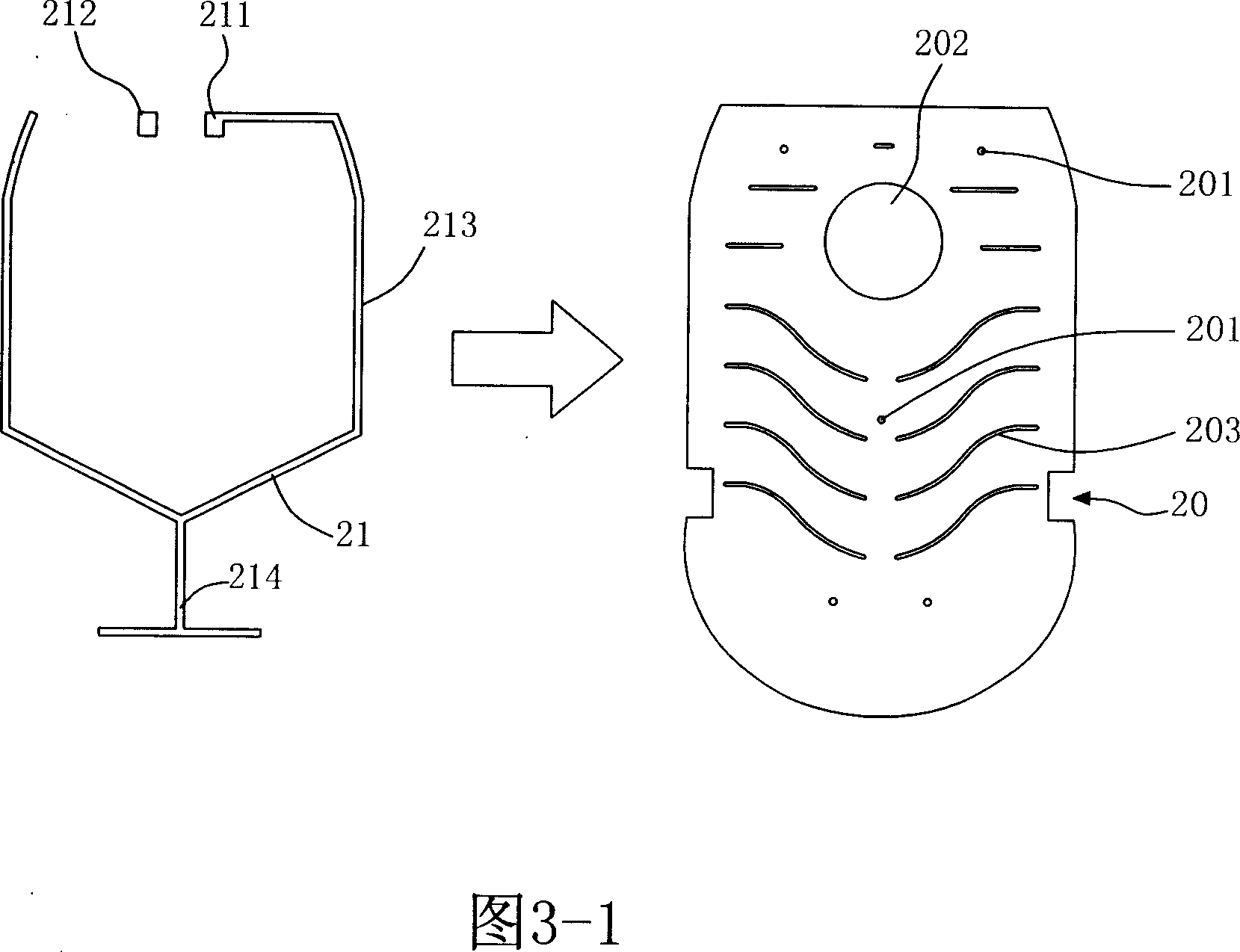

[0082] Please refer to FIG. 2 , FIG. 3-1 to FIG. 3-10 , and FIG. 4 , which disclose a preferred embodiment of the electroluminescence key device of the present invention. Wherein, FIG. 2 is a schematic diagram showing the composition sequence of each circuit layer in the electroluminescence key device of the present invention. 3-1 to 3-10 are schematic diagrams of the manufacturing process of the electroluminescence key device of the present invention. FIG. 4 is a three-dimensional exploded schematic diagram of each circuit layer of the electroluminescence key device of the present invention.

[0083] As shown in FIG. 2 and FIG. 4 , and referring to FIG. 3-1 to FIG. 3-10 , the manufacturing process of each circuit layer of the electroluminescence key device of the present invention is shown. The electroluminescence key device 2 of the present invention is mainly formed sequentially by printing on a substrate 20: a metal wire layer 21, a transparent insulating layer 22, a carb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com