Small-sized axial flow fan shell production method

A manufacturing method and technology of axial flow fans, applied to machines/engines, components of pumping devices for elastic fluids, mechanical equipment, etc., can solve problems such as insufficient strength, high cost, and easy damage, and achieve integrity Good, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

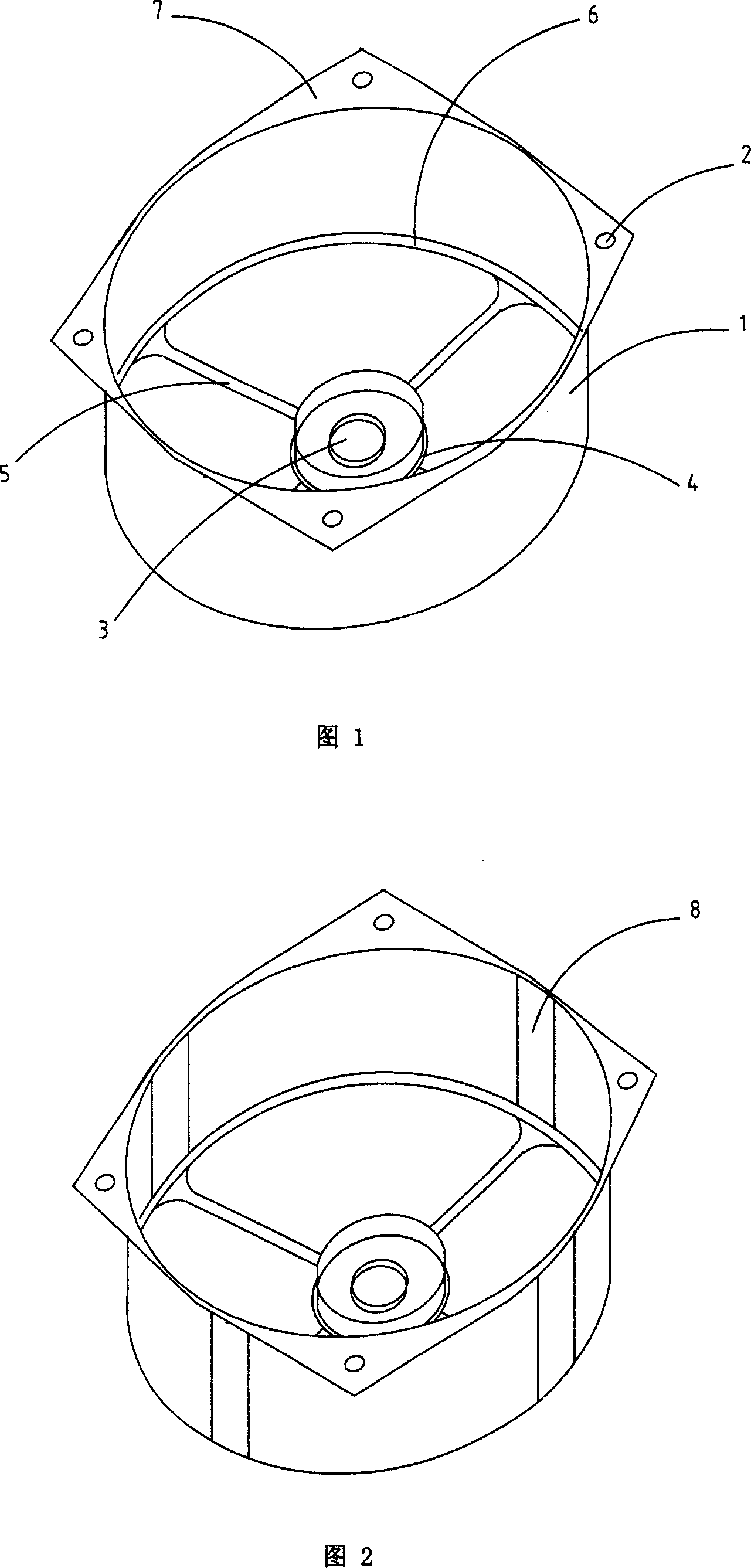

[0019] Referring to Fig. 1, a small axial flow fan casing of the present invention is made of cold-rolled steel plate with a thickness of 0.7-1.5mm, and its manufacturing method includes the following steps:

[0020] a. Blanking;

[0021] b. Using a model with a smooth cylindrical wall, the material is stretched into a cylinder 1;

[0022] c. Punching; leave the central end cover 4 and support rod 5 at the bottom of the stretched cylinder, and punch the rest;

[0023] d. Reverse lip and folded edge; carry out reverse lip 7 treatment on the upper mouth of the cylinder body; the periphery of the hole punched at the bottom of the cylinder body 1 and the upper mouth of the cylinder body are folded 6;

[0024] e. Fix the bearing seat 3 by spot welding on the end cover 4;

[0025] f. Drill installation holes 2 on the reverse lip 7 of the barrel mouth, and the installation holes 2 are evenly distributed along the upper mouth;

[0026] g. Finished product after surface coating trea...

Embodiment 2

[0029] Referring to Fig. 2, a small axial flow fan casing of the present invention is made of cold-rolled steel plates with a thickness of 0.5-0.7mm. The manufacturing method is that in step b of Example 1, the smooth cylindrical wall surface of the drawing die is changed to 4-8 concave curved surfaces with "Ω"-shaped cross-sections are evenly distributed along the axial direction of the cylindrical wall, and the material is stretched into a cylinder with this drawing die; Squeeze to make it folded and fit with other cylinder walls of the cylinder to form the reinforcing rib 8 of the cylinder; repeat Example 1 for the rest.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap