Method for removing methylene of gingili wood phenols

A methyleneation and lignification technology, applied in organic chemistry and other fields, can solve problems such as increased side reactions and reduced product purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

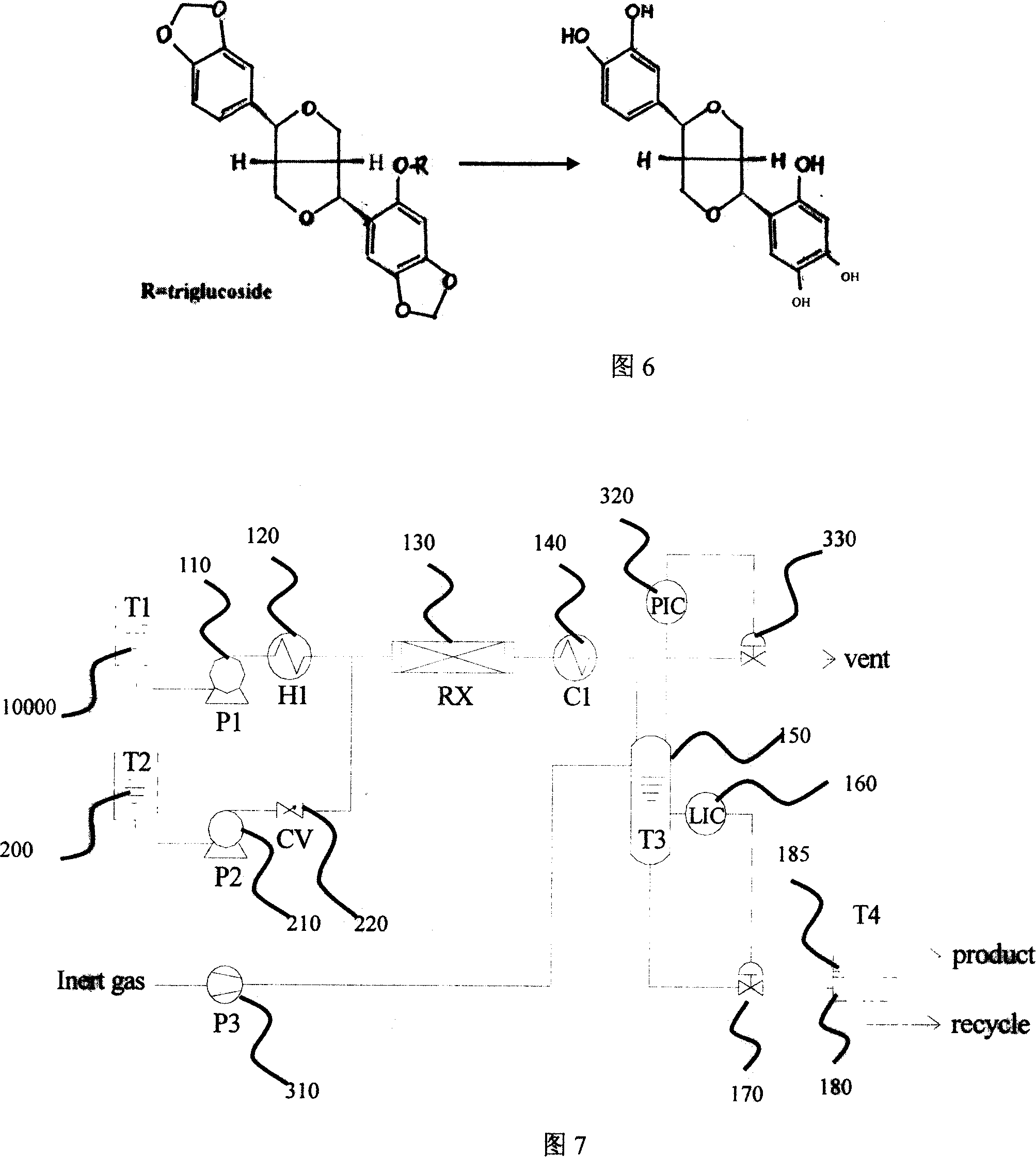

[0056] In order to make the purpose, features, and advantages of the present invention more clearly understood by those skilled in the art, preferred embodiments of the present invention will be described in detail below with accompanying drawings.

[0057] The specific embodiment of the present invention is shown in Figure 7, which is a flow chart of the demethylation reaction of sesame lignin. Its general mode of operation is as follows:

[0058](1) The water under normal temperature and pressure is temporarily stored in the T1 storage tank 100, and after being pressurized by the P1 high-pressure pump 110, it is heated to the set temperature by the H1 heat exchanger 120;

[0059] (2) MDP sesamin is temporarily stored in T2 storage tank 200, and through P2 high-pressure pump 210, after pressurization, it merges with high-temperature and high-pressure water and enters RX reactor 130. If necessary, a check valve 220 can be installed before the merger;

[0060] (3) The aqueous ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com