Adjustable metal composite type low-yield point damper

A low-yield point, composite technology, applied in building components, shockproof, etc., can solve the problems of high maintenance cost, unfavorable on-site installation and debugging, and shock absorption effect lower than the design value, etc., to achieve low material cost and reduced yield strength. , the effect of easy installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

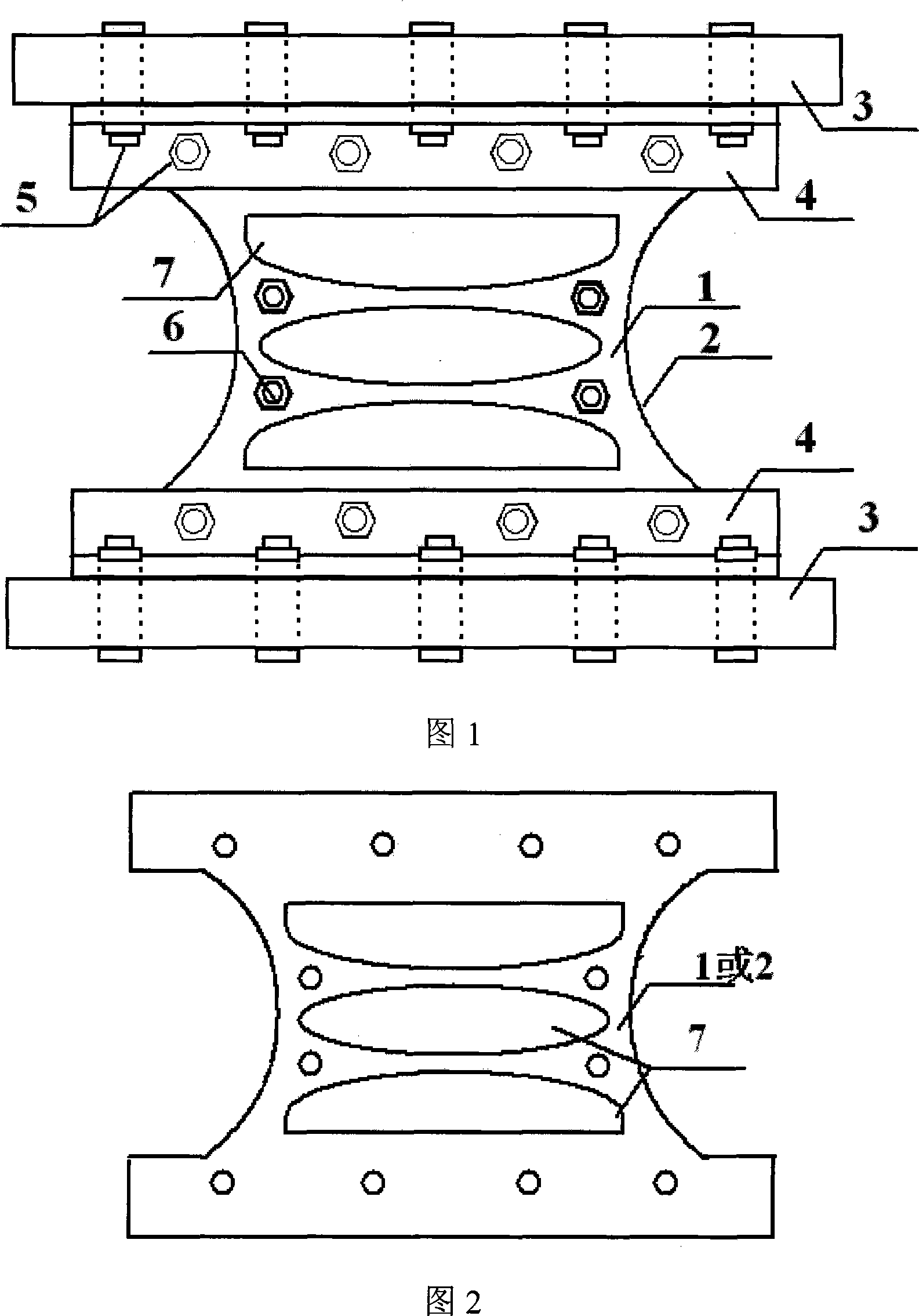

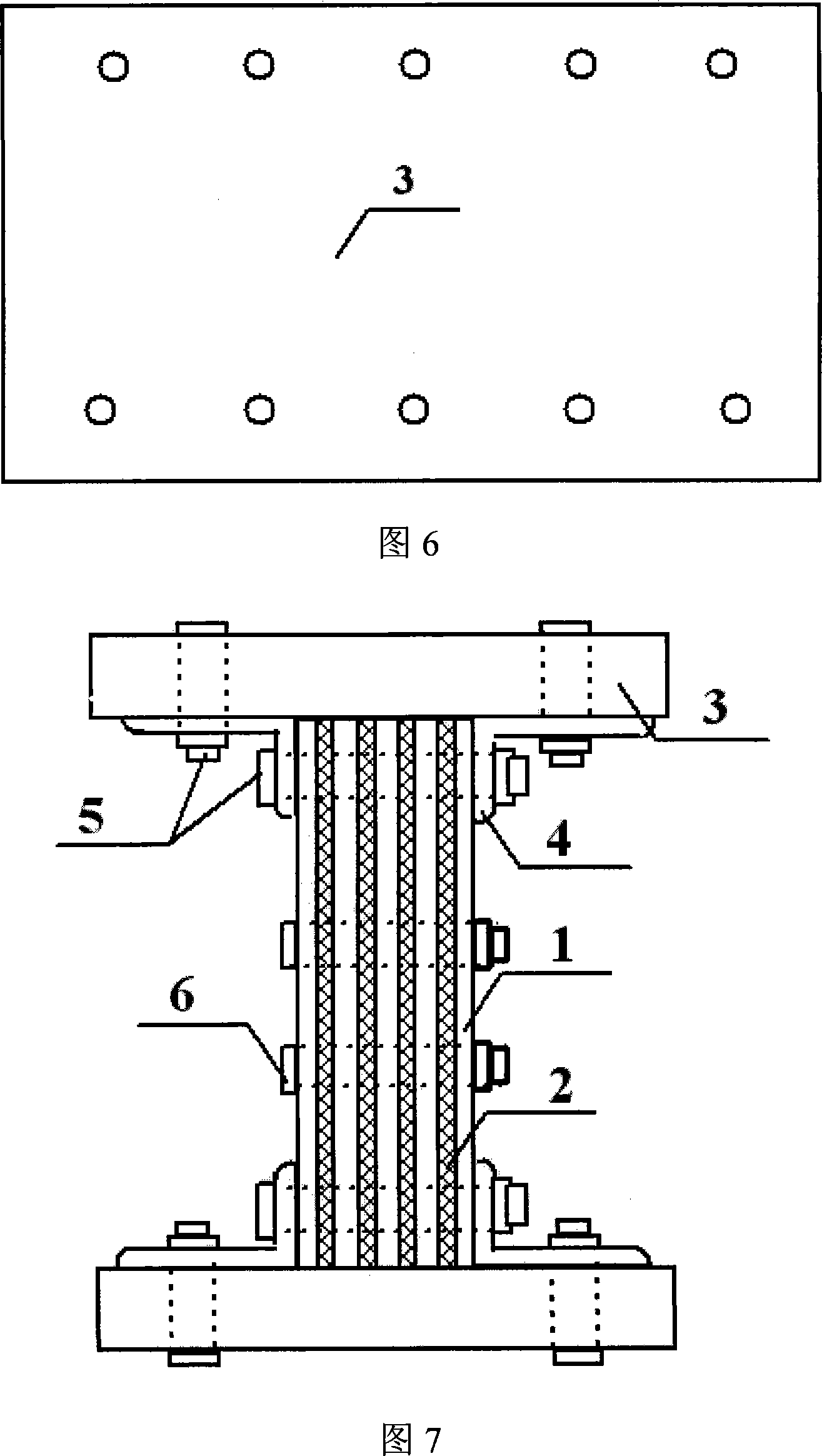

[0029] This embodiment mainly includes five first energy-dissipating metal plates 1 with higher yield points, four second energy-dissipating metal plates 2 with lower yield points, angle steel plates 4 and upper and lower horizontal connecting steel plates 3 . The upper and lower horizontal connecting steel plates 3 are connected with the building structure through large high-strength bolts 5 . Five first energy-dissipating metal plates 1 and four second energy-dissipating metal plates 2 are arranged alternately, as shown in Figure 7 and Figure 8, the shapes of the first energy-dissipating metal plates 1 and the second energy-dissipating metal plates 2 are exactly the same, The first energy-dissipating metal plate 1 is a low-carbon steel plate, the second energy-dissipating metal plate 2 is a zinc plate, and the ratio of the total thickness of...

Embodiment 2

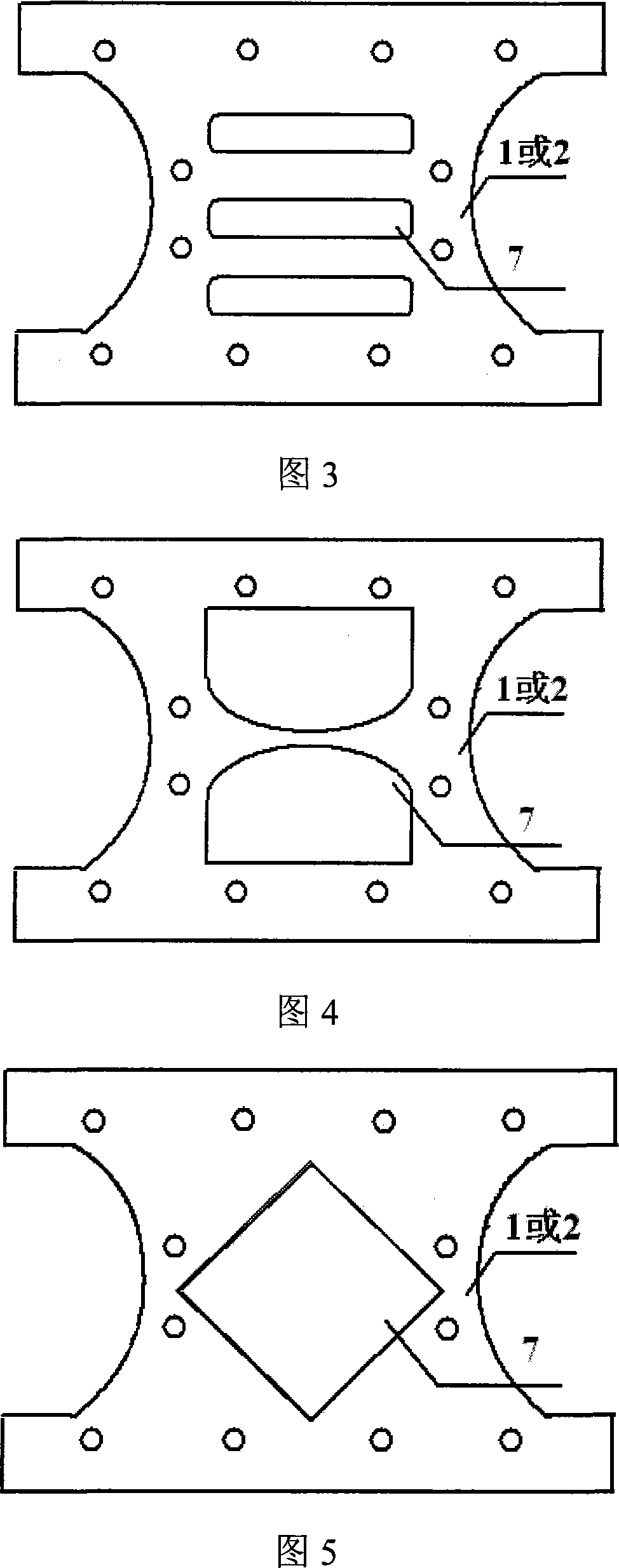

[0033] The structure of this embodiment is exactly the same as that of Embodiment 1, except that the first energy-dissipating metal plate 1 is a low-carbon steel plate, the second energy-dissipating metal plate 2 is a lead plate, and the total thickness of the low-carbon steel plate is the same as The total thickness ratio of the lead plate is 0.4:0.6. The hollow shapes of the first energy-dissipating metal plate 1 and the second energy-dissipating metal plate 2 are parallel rounded rectangles, as shown in FIG. 3 .

Embodiment 3

[0035] The structure of this embodiment is exactly the same as that of Embodiment 1, except that the first energy-dissipating metal plate 1 is an aluminum alloy plate, the second energy-dissipating metal plate 2 is a zinc plate, and the total thickness of the aluminum alloy plate is the same as that of the zinc plate. The total thickness ratio is 0.4:0.6. The hollow shapes of the first energy-dissipating metal plate 1 and the second energy-dissipating metal plate 2 are rhombus, as shown in FIG. 5 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| Yield strength | aaaaa | aaaaa |

| Yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com