Hydraulic propeller of pressure-regulating speed-changing draught fan used for energy-saving cooling tower

A variable-speed fan and cooling tower technology, applied in hydropower, machines/engines, mechanical equipment, etc., can solve the problems of low fan speed, poor thermal performance of cooling towers, freezing of cooling towers, etc., to improve efficiency and service life, Effect of improving thermal performance and avoiding icing accidents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

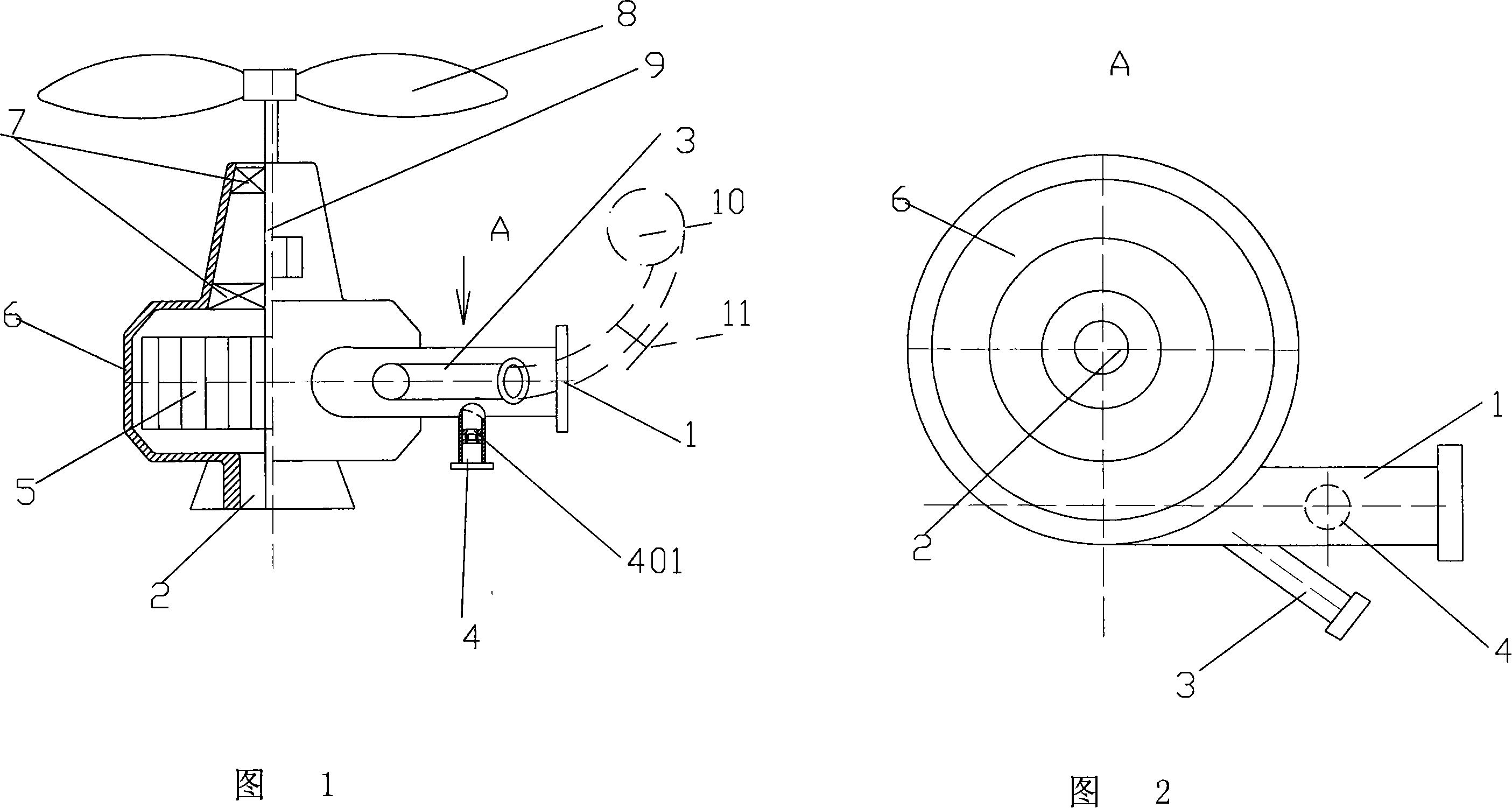

[0016] A pressure-regulating variable-speed fan hydraulic propeller for an energy-saving cooling tower, comprising: the output shaft 9 of the turbine is equipped with fan blades 8, the output shaft 9 is installed in the casing 6 of the turbine through a bearing 7, and the casing of the turbine The body 6 is provided with a water inlet pipe 1 and a water outlet pipe 2, and the water inlet pipe 1 is provided with a booster pipe 3 and a decompression water pipe 4.

[0017] The decompression water pipe 4 is provided with a decompression valve 401 or the decompression water pipe 4 is connected to the decompression valve 401 .

[0018] The booster pipe 3 communicates with the booster water pump 10 through a valve 11 .

[0019] The booster water pump extracts a part of the water at the tail of the turbine, that is, behind the water outlet pipe. The decompression water pipe is connected to the water distribution system of the cooling tower through the decompression valve 401. Therefo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com