Double-deck railway vehicle

A railway vehicle, double-deck technology, applied in the field of sleeping cars and/or daybeds, can solve the problems of reduced vehicle transportation capacity, stair occupancy, and expensive manufacturing, and achieves the effect of high transportation capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

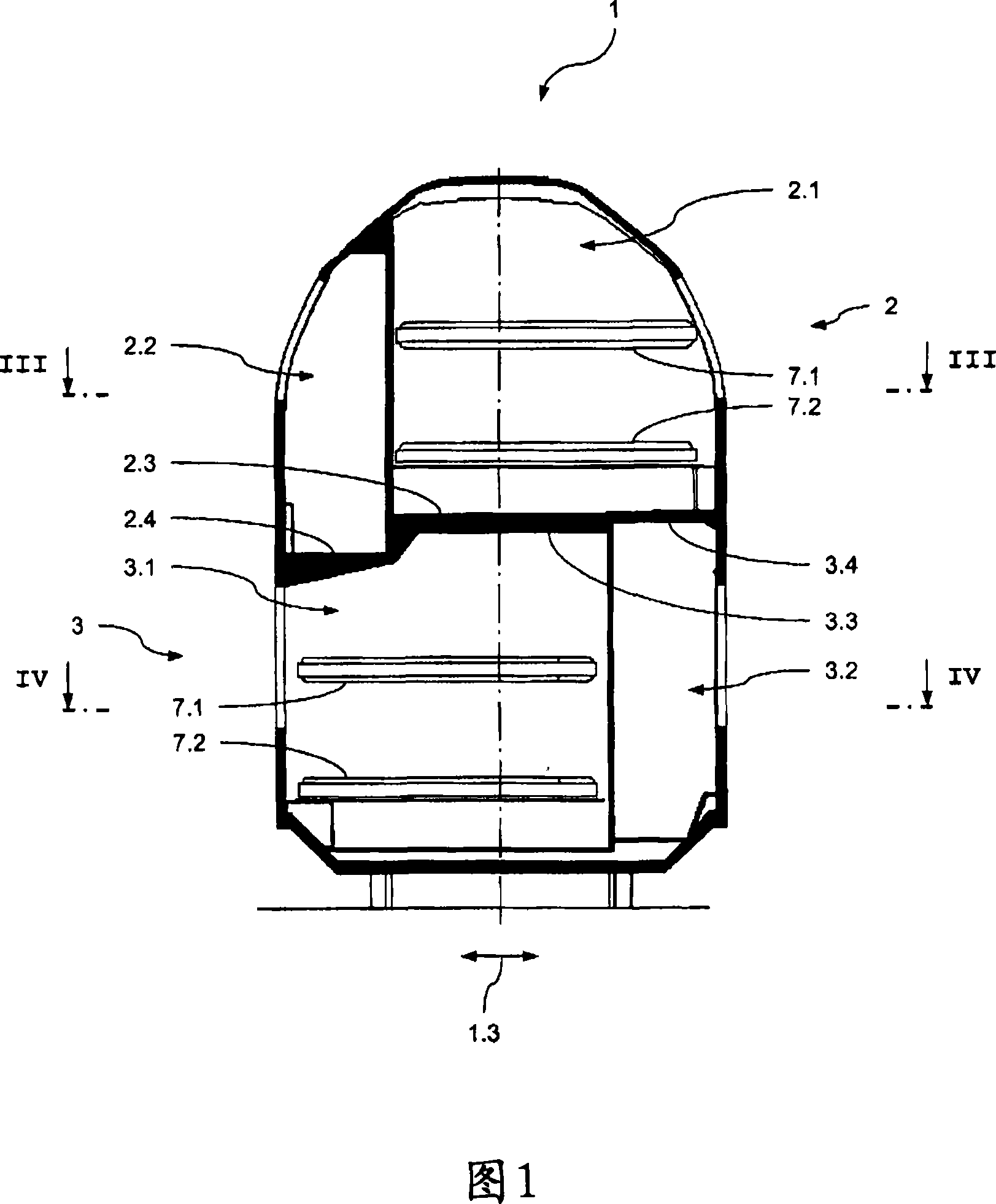

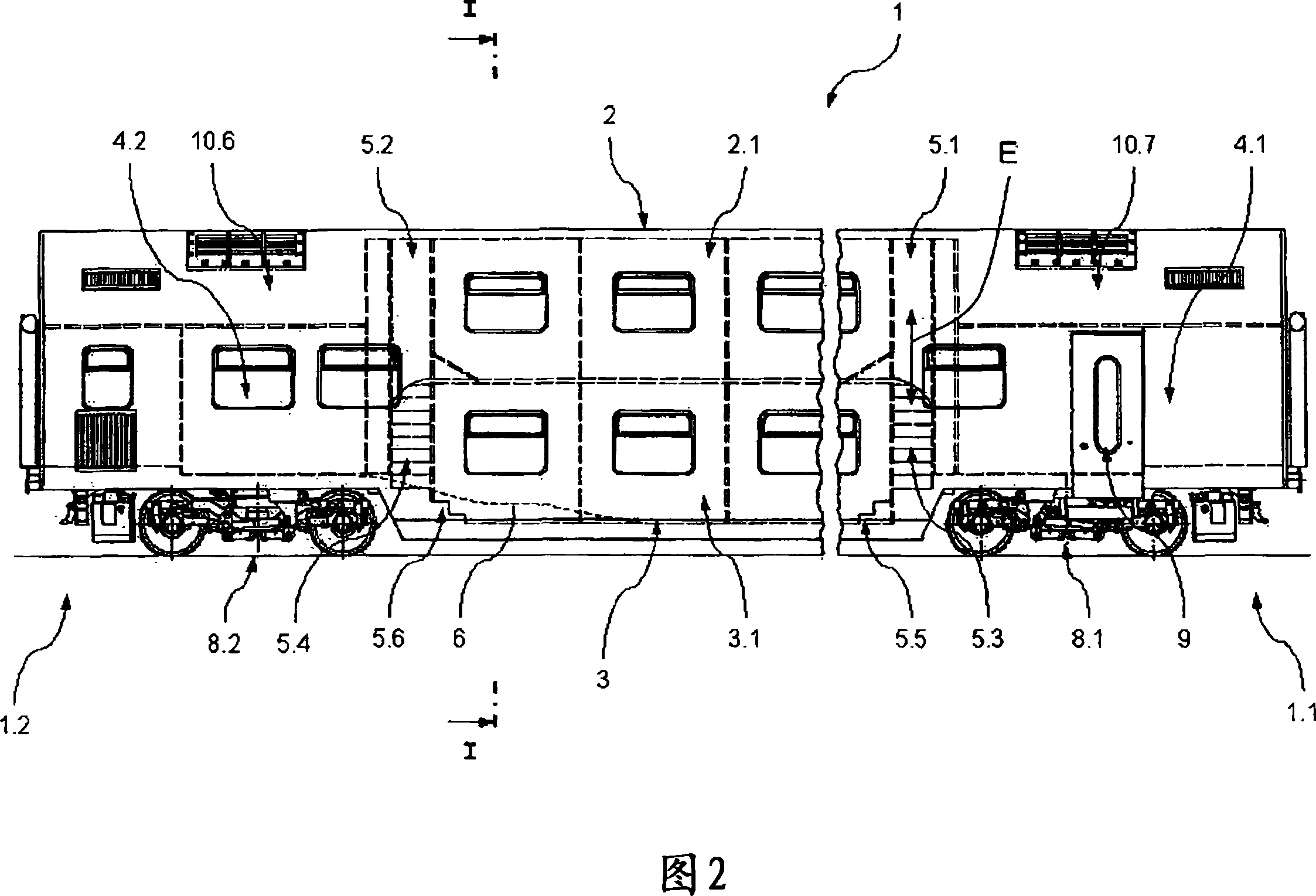

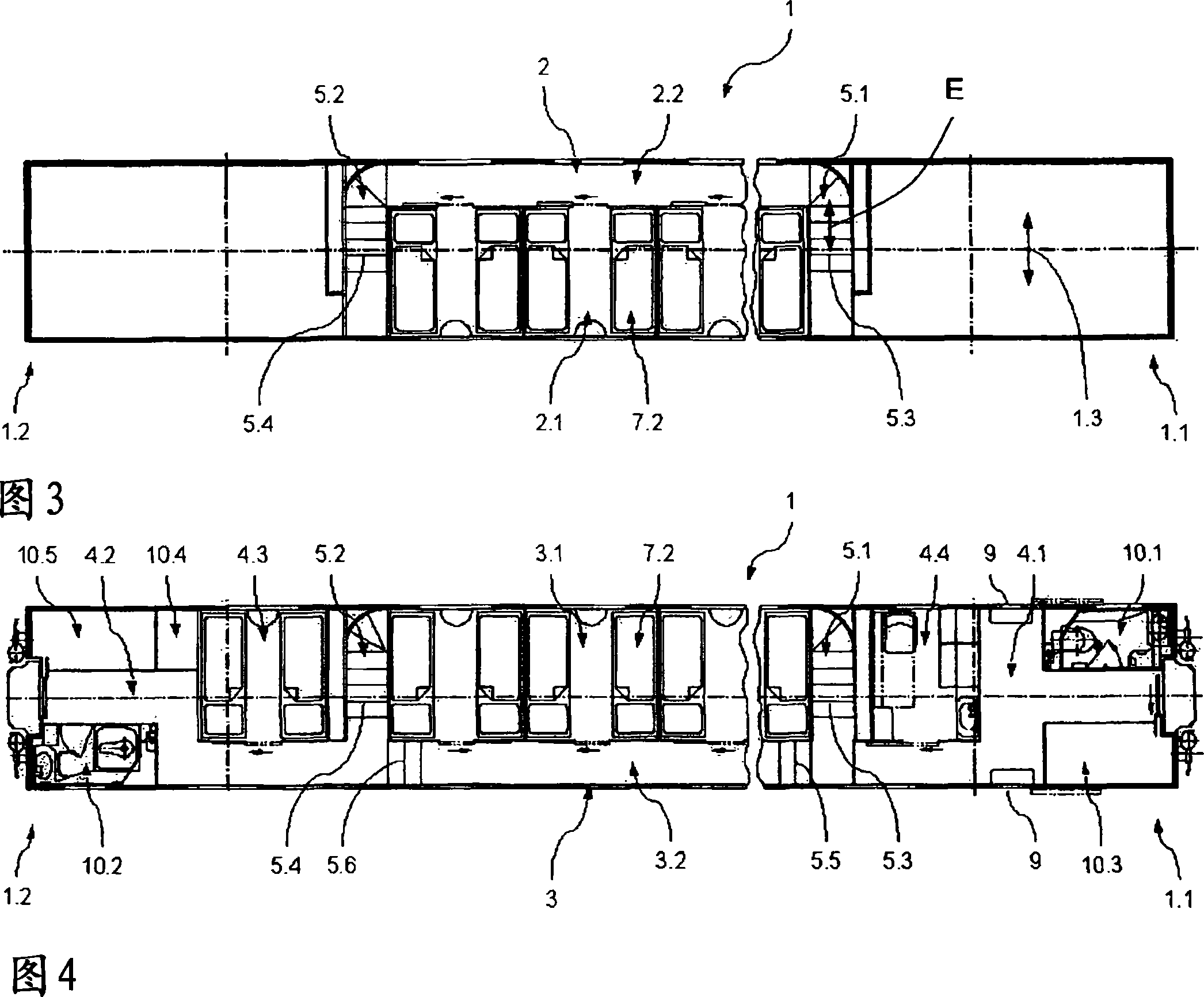

[0038] In the following a preferred embodiment of a double deck railway vehicle 1 according to the invention will be described with reference to FIGS. 1-4.

[0039] In a schematic view, Fig. 1 shows a cross-section of a double-decker railway vehicle 1 arranged perpendicularly to the longitudinal axis of the vehicle along the line I-I of Fig. 2 . Figure 2 shows a schematic side view of the vehicle. 3 and 4 show schematic cross-sectional views of the vehicle 1 along lines III-III and IV-IV of FIG. 1 , respectively.

[0040] The vehicle 1 comprises an upper level 2 and a lower level 3 in its middle part between the vehicle ends 1.1 and 1.2. The middle car floors 4.1 and 4.2 are respectively located near the two ends of the vehicle 1.1 and 1.2, and the upper car floor 2 and the lower car floor 3 enter from the middle car floor through stairs 5.1 and 5.2 respectively.

[0041] The upper level 2 has a plurality of upper carriages 2.1 and an upper passage 2.2 through which each upp...

no. 2 example

[0060] Another preferred embodiment of a double-deck railway vehicle 101 according to the present invention will be described below with reference to FIGS. 5-8 .

[0061] In a schematic view, Figure 5 shows a cross-section of a double-decker railway vehicle 1 arranged perpendicularly to the longitudinal axis of the vehicle along the line V-V of Figure 6 . Figure 6 shows a schematic side view of the vehicle. 7 and 8 show schematic cross-sectional views of the vehicle 101 along lines VII-VII and VIII-VIII of FIG. 5 , respectively.

[0062] Vehicle 101 corresponds in its basic design and function to vehicle 1 of FIGS. 1-4 . In particular, in FIGS. 5-8 , like components are indicated by reference numerals only increased by the number 100 . Because of the broad agreement between the embodiments of Figures 1-4 and Figures 5-8, differences are primarily referred to here.

[0063] As can be seen from FIG. 5 , one difference relates to the provision of the upper compartment 102.1 of...

no. 3 example

[0071] A further preferred embodiment of a double-deck railway vehicle 201 according to the invention will be described below with reference to FIG. 9 . In a schematic view FIG. 9 shows a cross-section of a double-decker railway vehicle 1 arranged perpendicular to the longitudinal axis of the vehicle 201 .

[0072]Vehicle 201 corresponds in its basic design and function to vehicle 1 of FIGS. 1-4 . In particular, in FIG. 9 , like components are indicated by reference numerals only increased in number by 200 . Because of the broad agreement between the embodiments of FIGS. 1-4 and FIG. 9 , differences are primarily referred to here.

[0073] The essential difference is that the upper level 202 is designed with a central upper aisle 202 .

[0074] Although the lower level 203 is designed similarly to the lower level 3 of FIG. 1 , the upper level has upper compartments 202.1 that are located on both sides of the upper aisle 202.2 and include sleepers 207.1 arranged in the longit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com