Method for etching having a controlled distribution of process results

An etching and process technology, applied in the field of etching with controlled process result distribution, can solve the problem of not having enough mechanism to control the temperature distribution of the substrate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

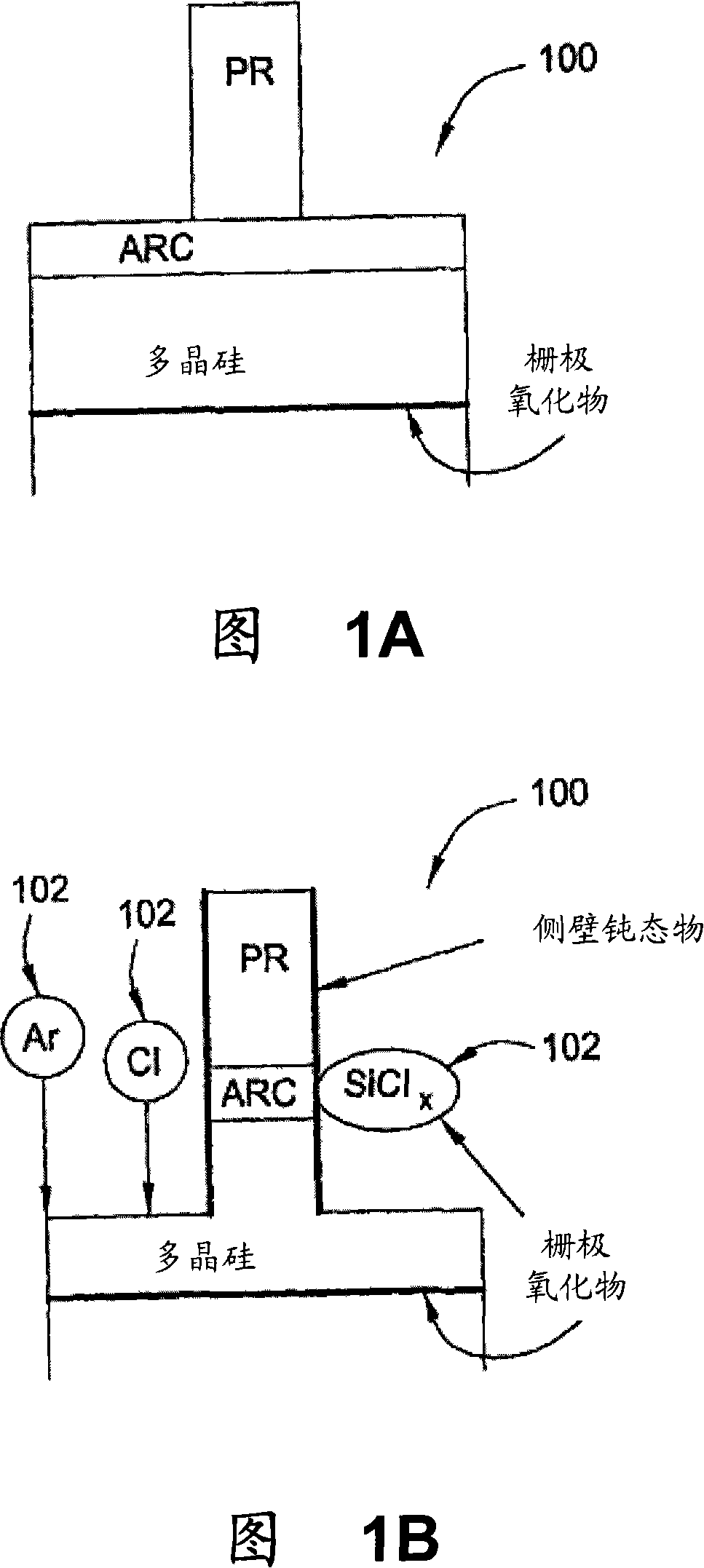

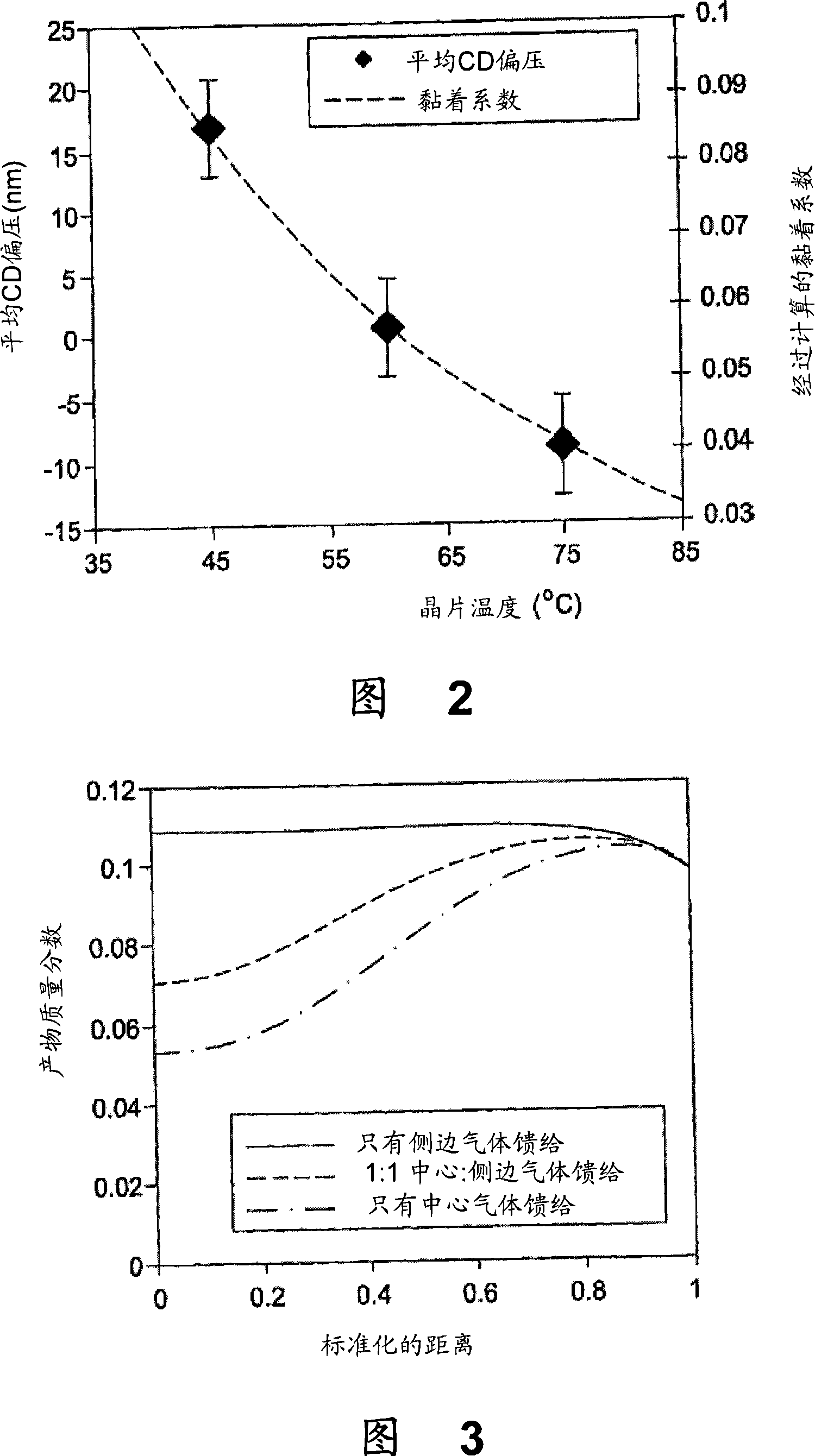

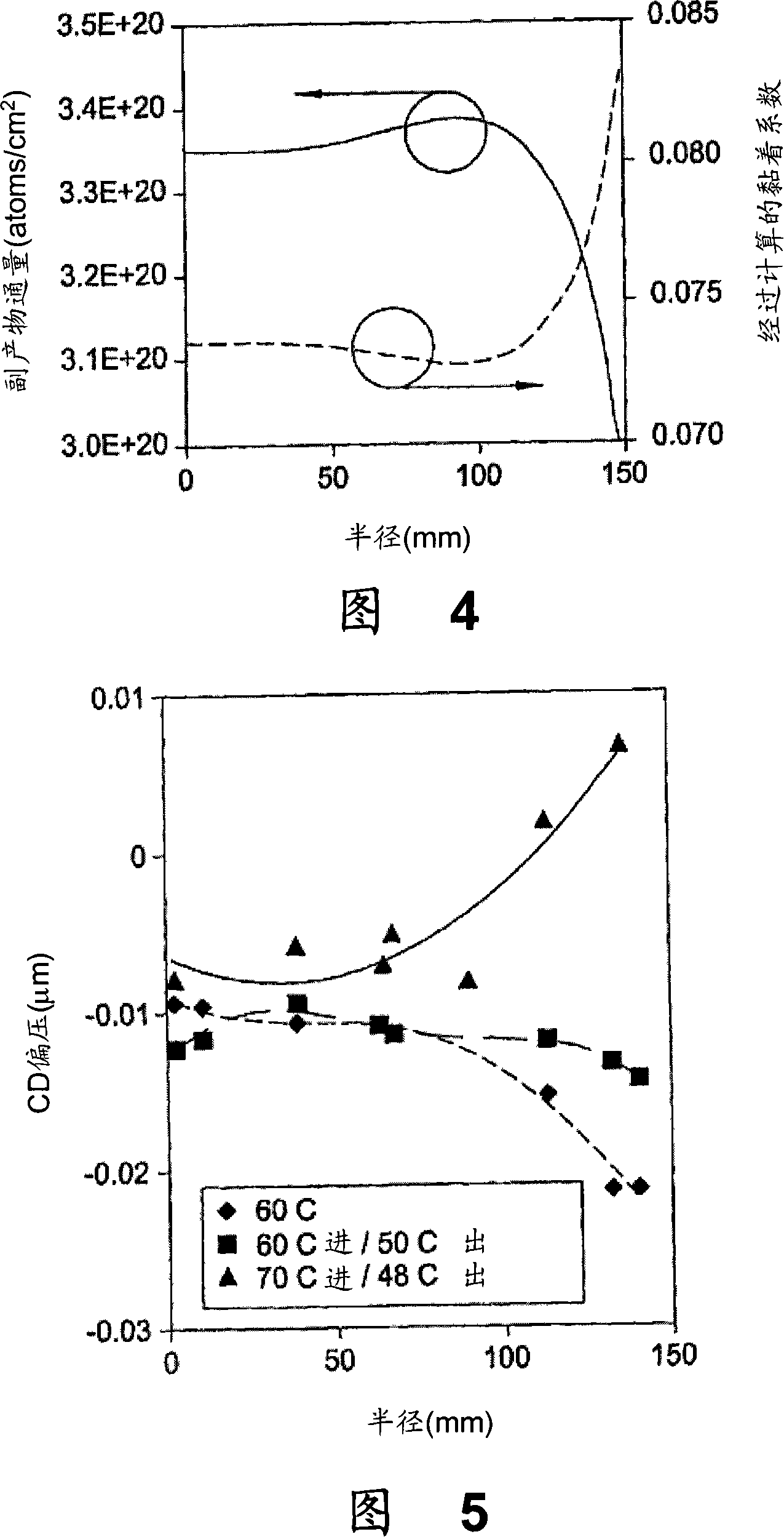

[0049] A schematic diagram of the gate etch process is shown in FIGS. 1A-B . We have experimentally observed a strong dependence of gate etch bias on substrate temperature and will now reveal this relationship and show the dependence of the gate etch by-product adhesion coefficient on substrate temperature, which allows Control over the distribution of process results across the substrate is possible.

[0050]This redeposition rate of etch byproducts is expected to follow the gas phase concentration of byproducts and the adhesion coefficient of these byproducts. The sticking coefficient has been used in gas-surface reaction mechanisms to describe the likelihood that an incident gas-phase species 102 will be absorbed into a surface (shown as a grid structure 100), and this coefficient is typically approximated by The ratio of the number of species reactively absorbed onto a surface to the total number of incident species. The analysis of the dependence of the adhesion coeffic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com