Heat insulating method for reduction tank slag hole and reduction tank prepared by the method

A reduction tank and slag outlet technology, applied in the field of heat insulation, can solve problems such as large heat loss, and achieve the effects of preventing scalding accidents, reducing temperature, and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

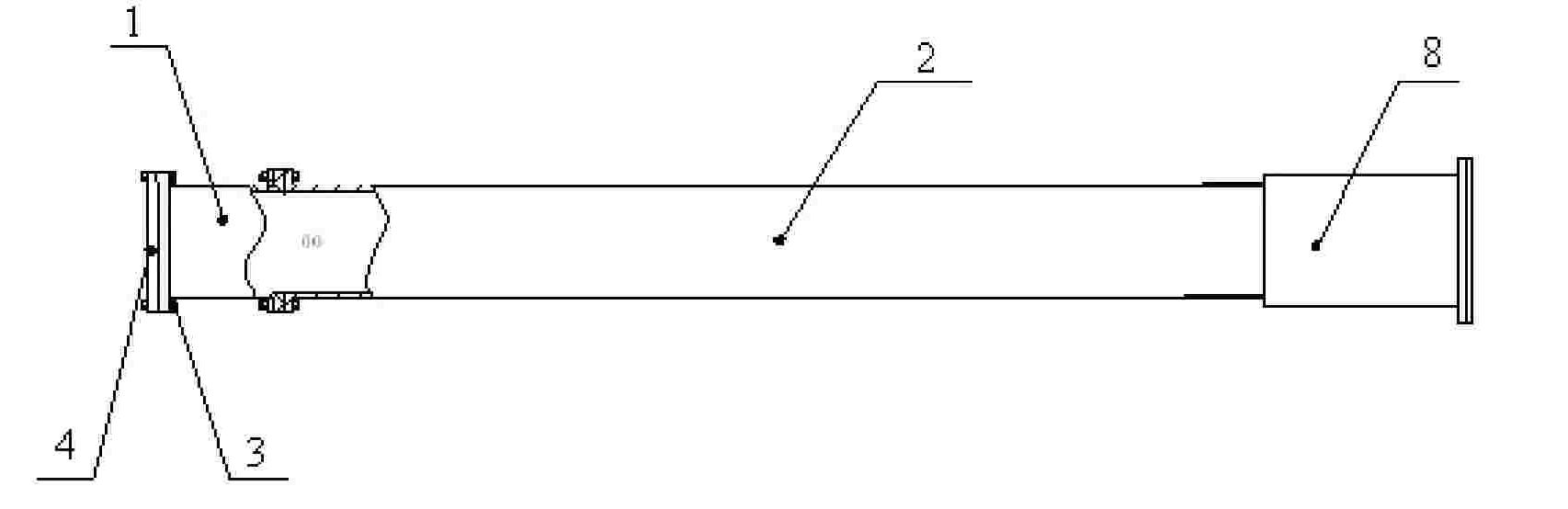

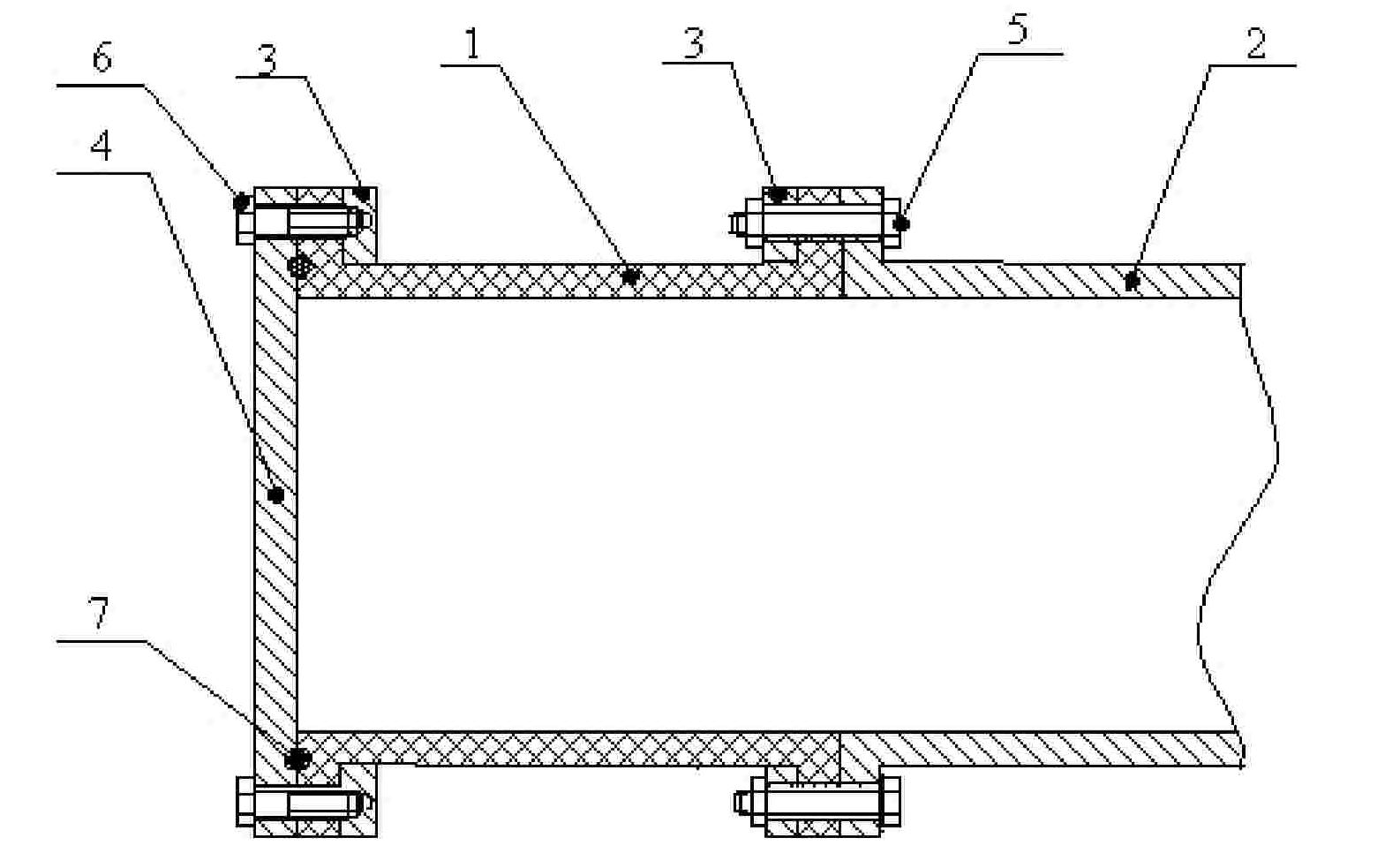

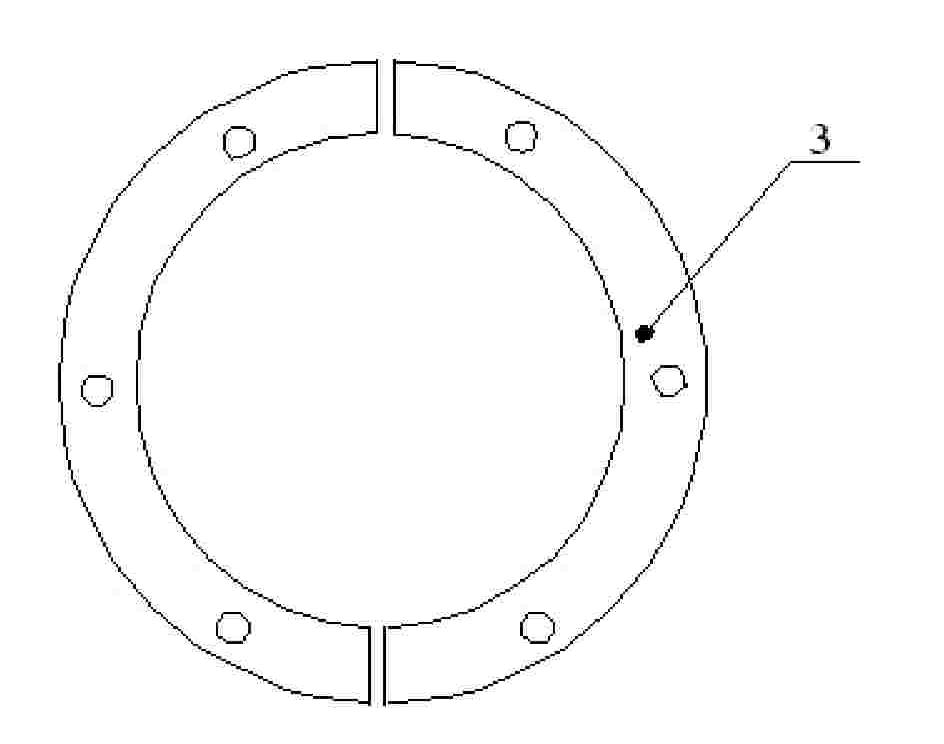

[0014] Embodiment: a heat insulation method for the slag outlet of a reduction tank, such as figure 1 , 2 , 3, the heat insulation section 1 made of non-metallic material is set at the slag outlet of the reduction tank, and the heat insulation section 1 is made of ceramic fiber non-metallic material with heat insulation effect, which blocks the kiln body with very high temperature. The transfer of heat from the reduction tank to the kiln body reduces the heat loss at the slag outlet, greatly reduces the temperature at the end cover of the slag outlet that needs to be disassembled frequently, and makes the sealing of the slag outlet easier to achieve, and The sealing is more reliable, and at the same time, workers do not need to open the end cover of the slag outlet to clean and restore waste slag at a very high temperature, which improves the working conditions of the workers and prevents scalding accidents.

[0015] The reduction tank prepared according to the heat insulatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com