Method for recognizing water boiling point with piezo-effect vibration pickups, and sensor and circuit

A technology of vibration sensor and piezoelectric effect, which is applied in the field of boiling water detection, can solve problems such as boiling point change cannot be quickly identified, temperature sensor time drift, temperature sensor deviation, etc., to achieve accurate and consistent boiling point response frequency change point, huge market value and economy The effect that the position of the value, the installation is flexible

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

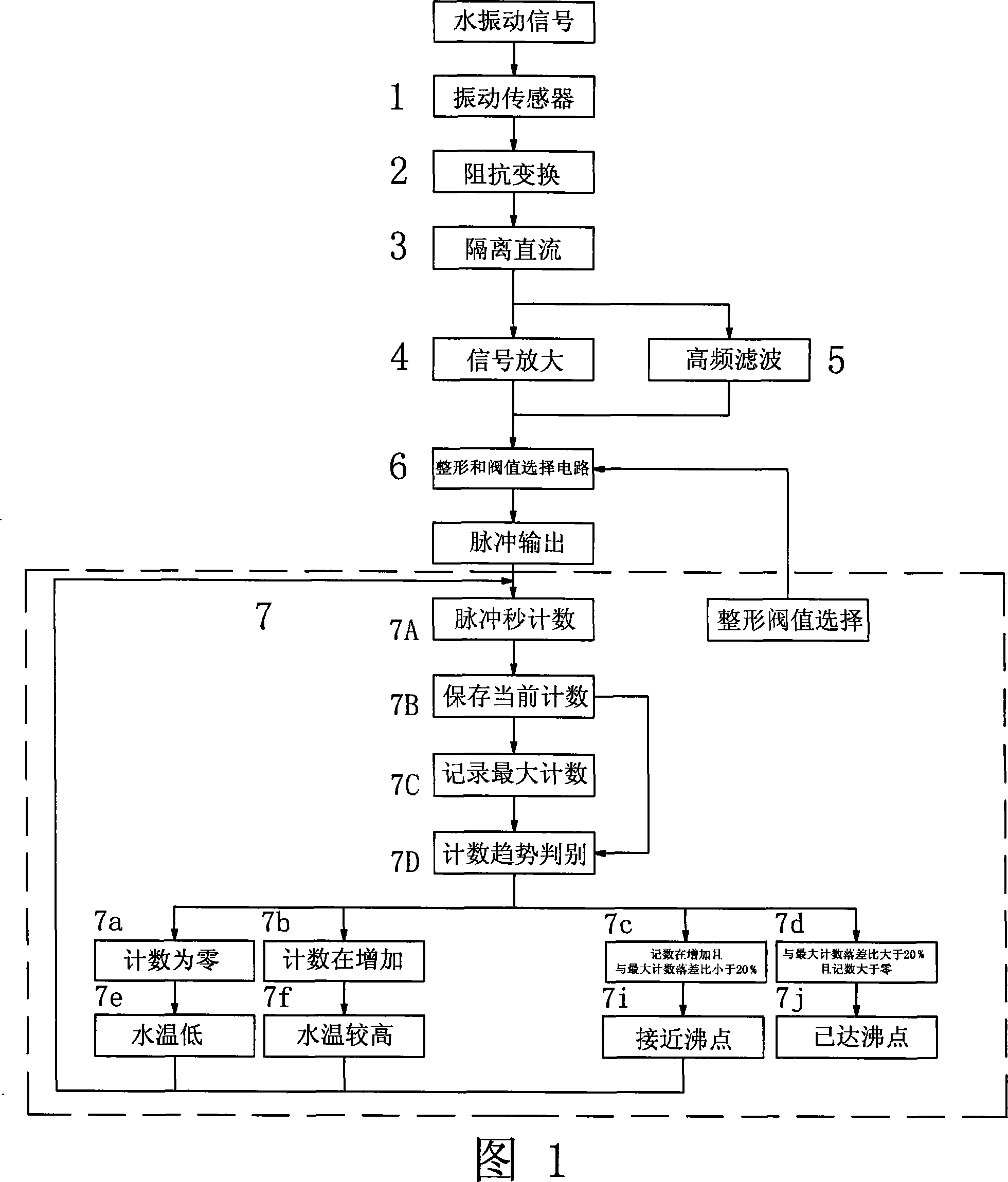

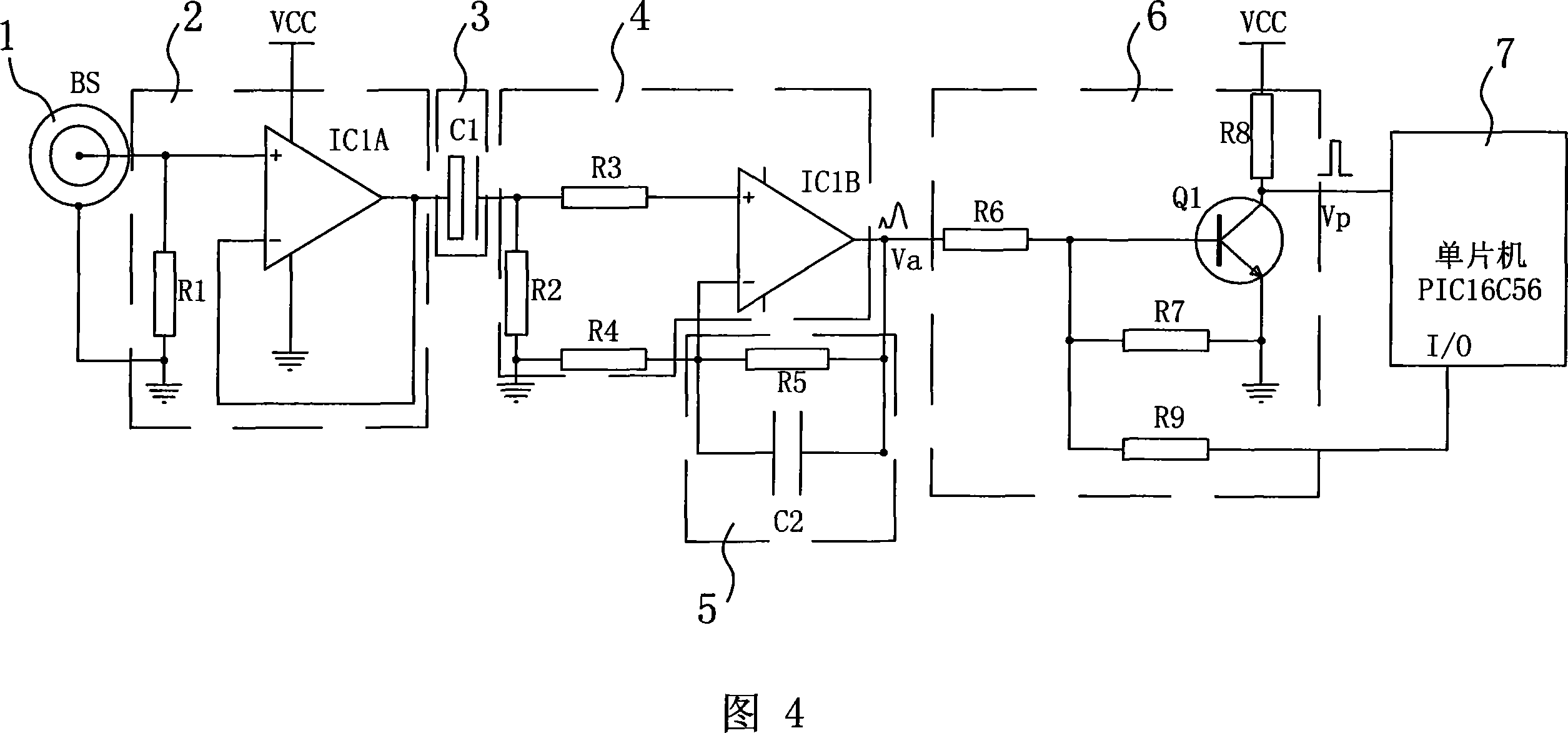

[0034] Referring to shown in Fig. 1, the method for identifying the boiling point of water with a piezoelectric effect vibration sensor of the present invention comprises the following steps;

[0035] (1) Use the piezoelectric effect vibration sensor to detect the vibration of water;

[0036] (2) Impedance transformation is carried out to the output signal of the piezoelectric effect vibration sensor;

[0037] (3) Isolate the DC component;

[0038] (4) Low frequency signal amplification;

[0039] (5) performing high-frequency filtering on the amplified low-frequency signal;

[0040] (6) The single-chip microcomputer selects to carry out low-threshold shaping processing on the filtered signal;

[0041] (7) Input the shaped pulse signal to the counting port of the single-chip microcomputer for the following processing: (A) carry out second counting and digital filtering; (B) save the current second count; (C) record the maximum second count; (D) compare the current seconds c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com