Non-contact type electrical apparatus line fault testing device

A detection device, non-contact technology, applied in the direction of fault location, line transmission monitoring/testing, line transmission parts, etc., can solve the problems of line fault disassembly, maintenance difficulties, damaged wires, and a lot of time, and achieve fast detection Convenient, small size, easy to carry effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Below in conjunction with accompanying drawing, the present invention is described in further detail:

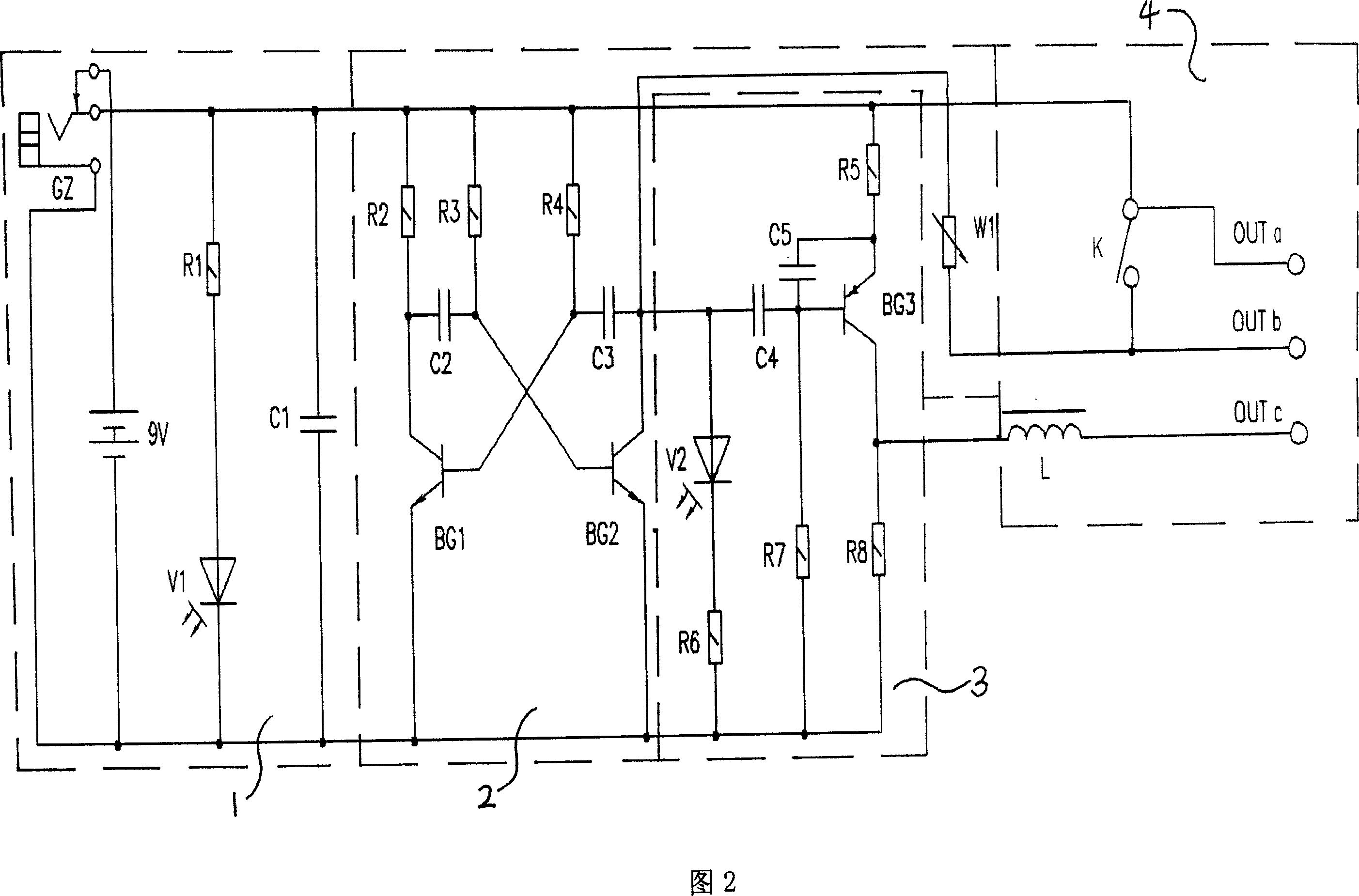

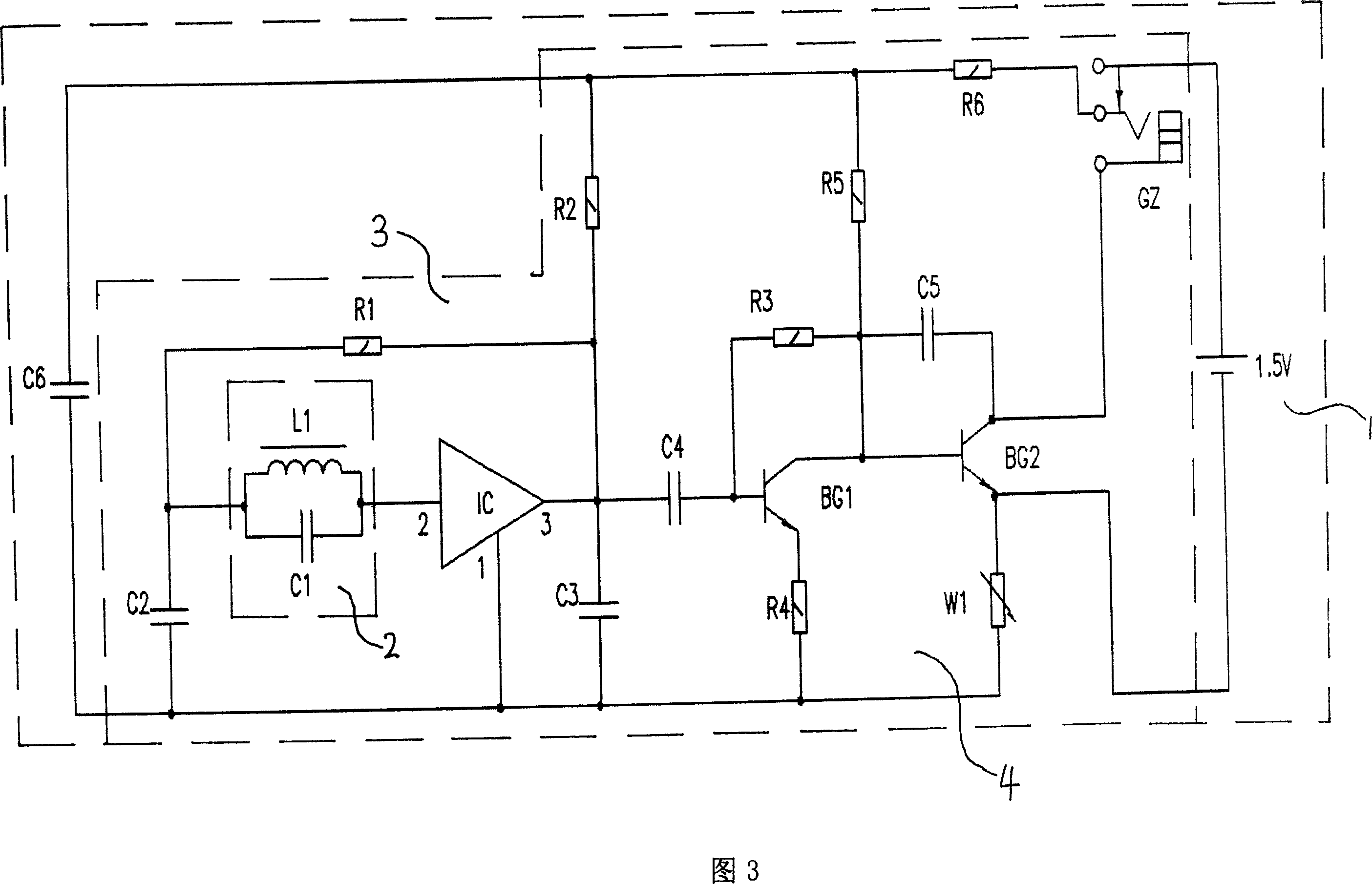

[0021] As shown in Figure 1, Figure 2, and Figure 3,

[0022] Component numbers and names in Figure 2: first resistor R1, 5K; second resistor R2, 5K; third resistor R3, 20K; fourth resistor R4, 20K; fifth resistor R5, 100K; sixth R6, 2K; The seventh resistor R7, 5K; the eighth resistor R8, 2K; the variable potentiometer W1, 10K; the first light-emitting diode V1, the second light-emitting diode V2; the first filter capacitor C1, 0.01uf; the second capacitor C2, 10n ; The third capacitor C3, 10n; the fourth capacitor C4, 15p; the fifth capacitor C5, 10uf; the inductance L; the switch K; the first triode BG1, 9014; Tube BG3, A733; GZ, Φ3.5mm external power socket;

[0023]Component numbers and names in Figure 3: first resistor R1, 100K; second resistor R2, 1.5K; third resistor R3, 27K; fourth R4, 100; fifth resistor R5, 1.5K; adjustable potentiometer W1 , 270; the fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com