Microsystem with electromagnetic control

A microsystem and magnetic technology, applied in the field of microsystems, can solve problems such as reducing the electrical performance of microactuators

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

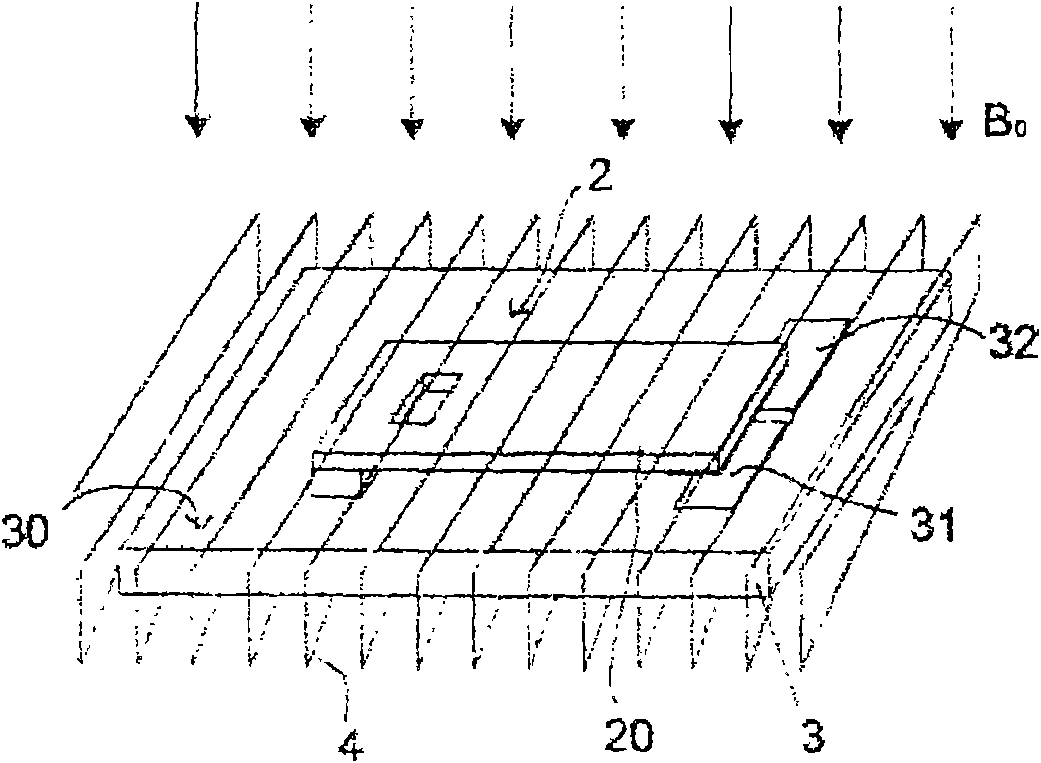

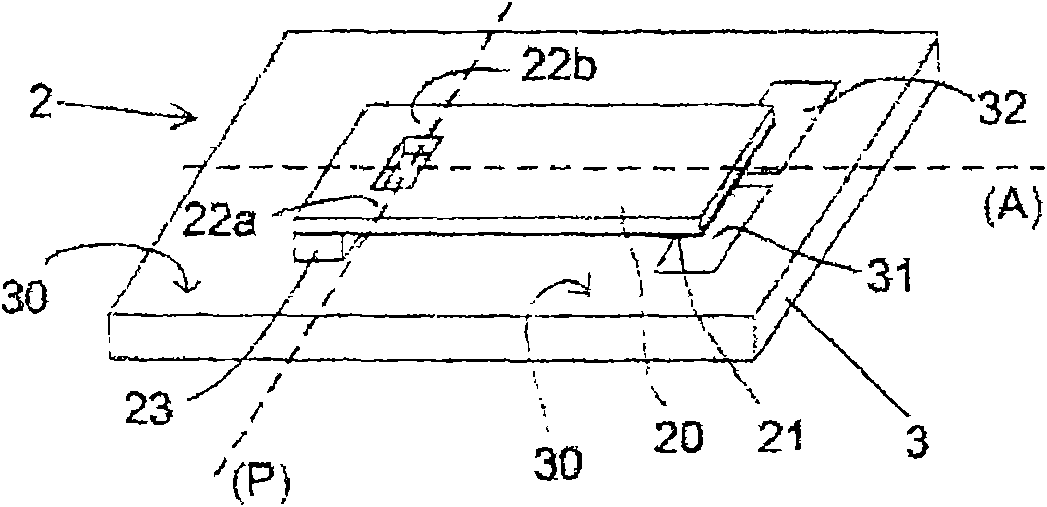

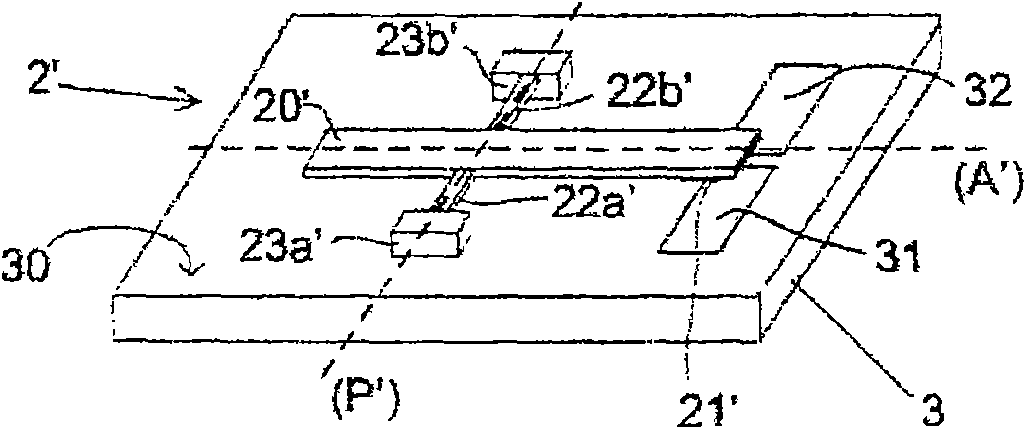

[0034] The present invention will refer to Figure 1-7 Be explained.

[0035] As described in the prior art above, the microsystem according to the invention uses magnetic microactuators 2, 2' to control the opening or closing of circuits.

[0036] refer to Figure 2A and 2B , the microsystem includes microactuators 2, 2' supported by a substrate 3. The substrate 3 is manufactured, for example, from a material such as glass, plastic or a good thermal conductor based on silicon or ceramics for applying electricity. The substrate 3 has a planar surface 30 on which the microactuators 2, 2' are fixed. As is known (cf. patent application US 2002 / 0140533), the substrate 3 carries eg at least two electrodes 31, 32 for electrical connection to close the electrical circuit ( Figure 2A and 2B ). To achieve this, the magnetic microactuator 2, 2' carries at least one movable contact 21, 21' capable of electrically connecting the two electrodes when the microactuator 2, 2' is activ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com