High-efficiency turbulent flow vibrating grinder

A grinding machine and turbulent flow technology, applied in the field of high-efficiency turbulent vibration grinding machines, can solve the problems of shortening the practical life, the gears are prone to resonance, and the service life of the gears is affected.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

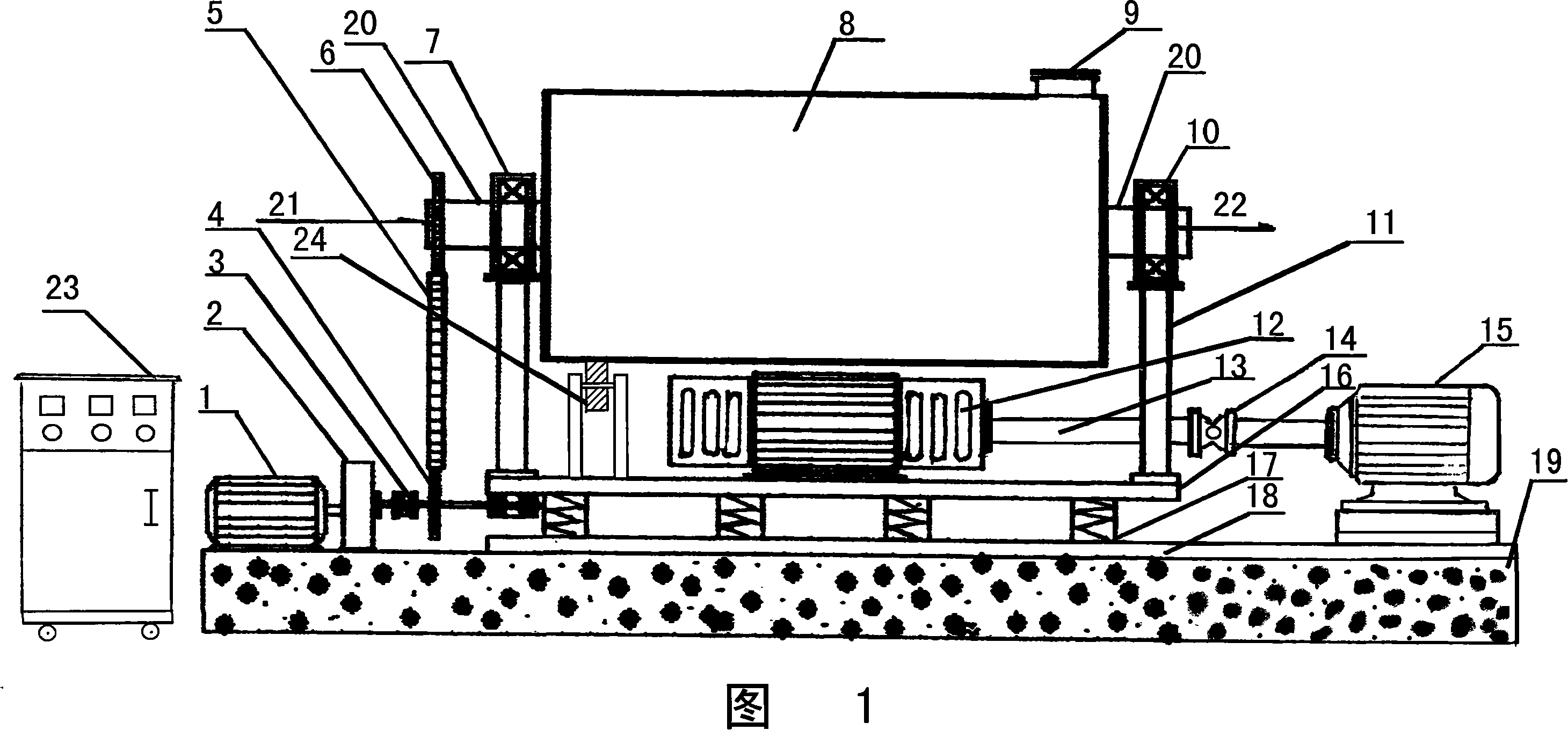

[0007] As shown in Figure 1, the rotary drive motor 1 of the high-efficiency turbulent vibration grinding machine is connected with a reducer 2, and the reducer 2 is connected with a universal transmission coupling 3, and the universal transmission coupling 3 can be connected with a belt Couplings or tire couplings. The universal drive coupling 3 is connected with a driving sprocket 4, the driving sprocket 4 is provided with a driving chain 5, and the other end of the driving chain 5 is linked with at least one driving sprocket 6, the A driving sprocket 6 is connected with a hollow shaft 20, and the two ends of the hollow shaft 20 are respectively provided with a feed port 21 and a discharge port 22, and the hollow shaft 20 is connected with the bearing housings 7, 10, and the bearing housings 7 and 10 are erected on the frame 11, and at least one rotating cylinder 8 is connected to the hollow shaft 20, and at least two rotating cylinders 8 may also be connected in series on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com