Biomass themal dissociation liquidation device and method for using same

A biomass pyrolysis and liquefaction device technology, applied in the field of biomass pyrolysis and liquefaction devices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

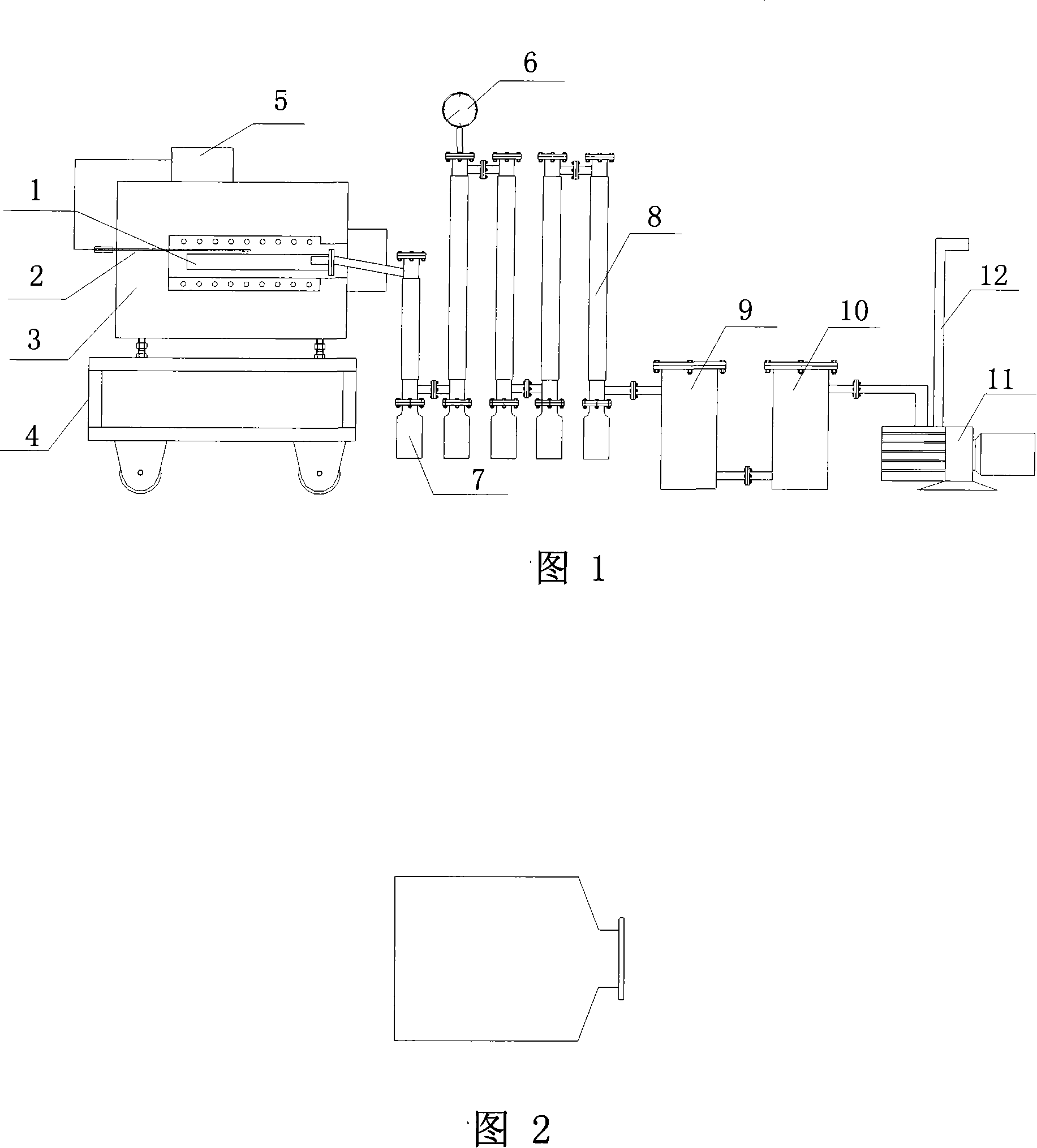

[0016] Example 1: Preparation of pyrolysis oil high in 1,6-anhydro-β-D-glucopyranose (abbreviation: inner ether sugar) by pyrolyzing corn stalks using the pyrolysis device shown in Figure 1

[0017] Put the crushed corn stalks into the reactor, connect the reactor with the cooler, and make the whole system well sealed, turn on the vacuum pump, and after the system reaches the maximum vacuum, quickly push it into the preheated (450°C) furnace , After reacting for 60 minutes, stop heating, separate the heating furnace from the reactor, after the reactor cools down, open the vent valve, turn off the vacuum pump, remove the collection bottle, and collect the pyrolysis oil. The yield of the pyrolysis oil accounts for about 70% (weight ratio) of the raw material, and the content of the inner ether sugar in the pyrolysis oil is about 25% (weight ratio), which can be further refined to obtain the inner ether sugar. The charcoal in the reactor is collected by unloading the reactor, and...

Embodiment 2

[0018] Example 2: Using the pyrolysis device shown in accompanying drawing 1 to pyrolyze sawdust to prepare pyrolysis oil with high inner ether sugar content

[0019] Put the sawdust into the reactor, connect the reactor with the cooler, and make the whole system well sealed, turn on the vacuum pump, and after the system reaches the maximum vacuum, quickly push it into the preheated (450°C) furnace, and react for 70 After 10 minutes, stop heating to separate the heating furnace from the reactor. After the reactor cools down, open the vent valve, turn off the vacuum pump, remove the collection bottle, and collect the pyrolysis oil. The yield of the pyrolysis oil accounts for about 60% (weight ratio) of the raw material, and the content of the inner ether sugar in the pyrolysis oil is about 20% (weight ratio), which can be further refined to obtain the inner ether sugar. The charcoal in the reactor is collected by unloading the reactor, and the productive rate of charcoal accoun...

Embodiment 3

[0020] Example 3: Using the pyrolysis device shown in accompanying drawing 1 to pyrolyze waste cotton to prepare pyrolysis oil with high content of endo-ether sugar

[0021] Add waste cotton into the reactor to seal the reactor and the cooler, and make the whole system well sealed, turn on the vacuum pump, after reaching the maximum vacuum, quickly push it into the preheated (450°C) furnace, and react for 60 minutes Finally, stop heating and separate the heating furnace from the reactor. After the reactor cools down, open the vent valve, turn off the vacuum pump, remove the collection bottle, and collect the pyrolysis oil. The yield of the pyrolysis oil accounts for about 70% (weight ratio) of the raw material, and the content of the inner ether sugar in the pyrolysis oil is about 65% (weight ratio), which can be further refined to obtain the inner ether sugar. The charcoal in the reactor is collected by unloading the reactor, and the productive rate of the charcoal accounts f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com