Back light source of planar display heat radiating device

A technology of a flat panel display and a heat dissipation device, which is applied to cooling/heating devices of lighting devices, lighting devices, components of lighting devices, etc., and can solve the problem of low thermal conductivity, reducing the heat dissipation efficiency of the backlight unit 6, and reducing the heat conduction efficiency of the circuit board 7 and other issues, to achieve the effect of prolonging the service life, improving assembly reliability, and improving heat dissipation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to make the above-mentioned and other purposes, technical features and advantages of the present invention more comprehensible, the preferred embodiments of the present invention are specifically cited below, together with the accompanying drawings, as follows:

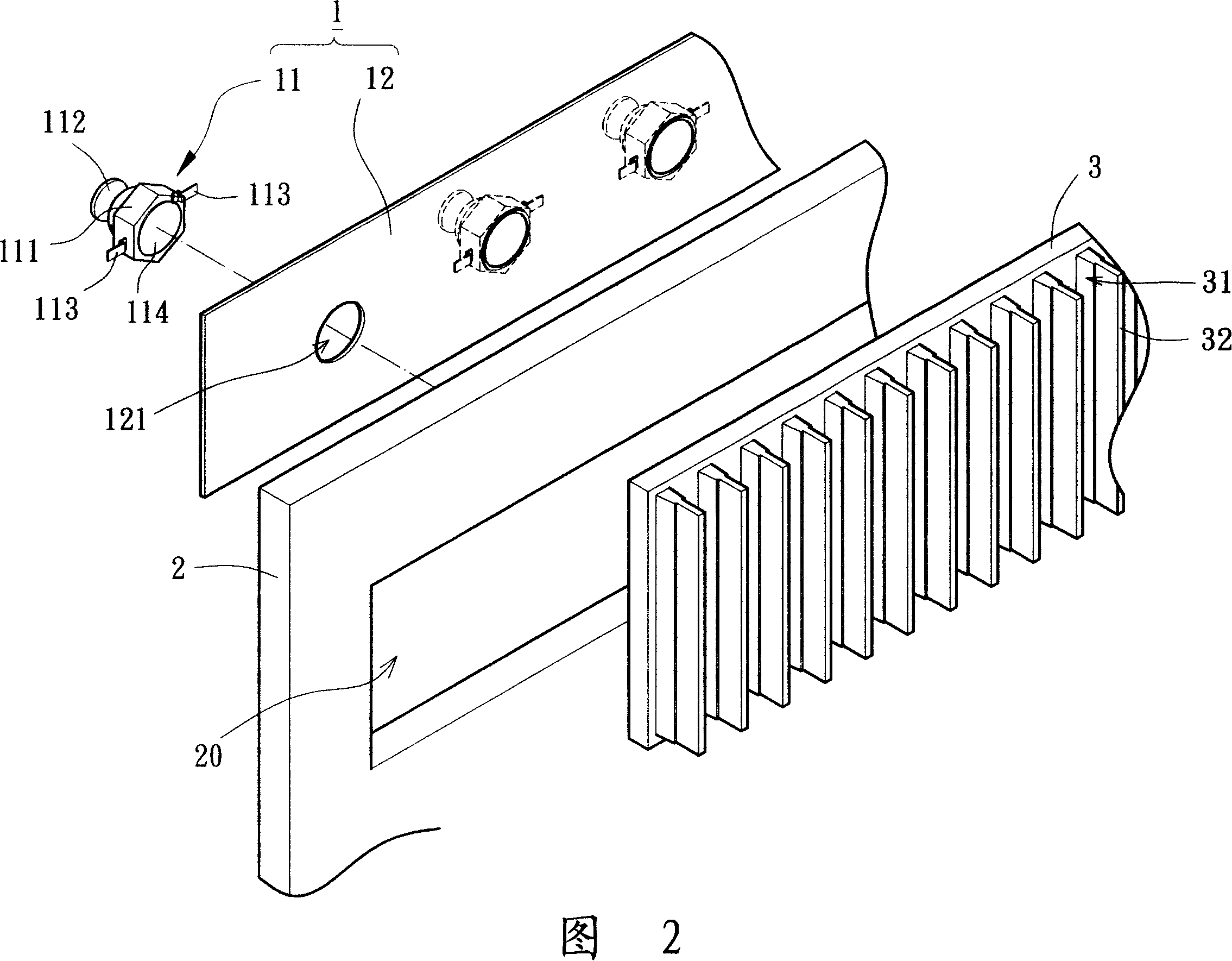

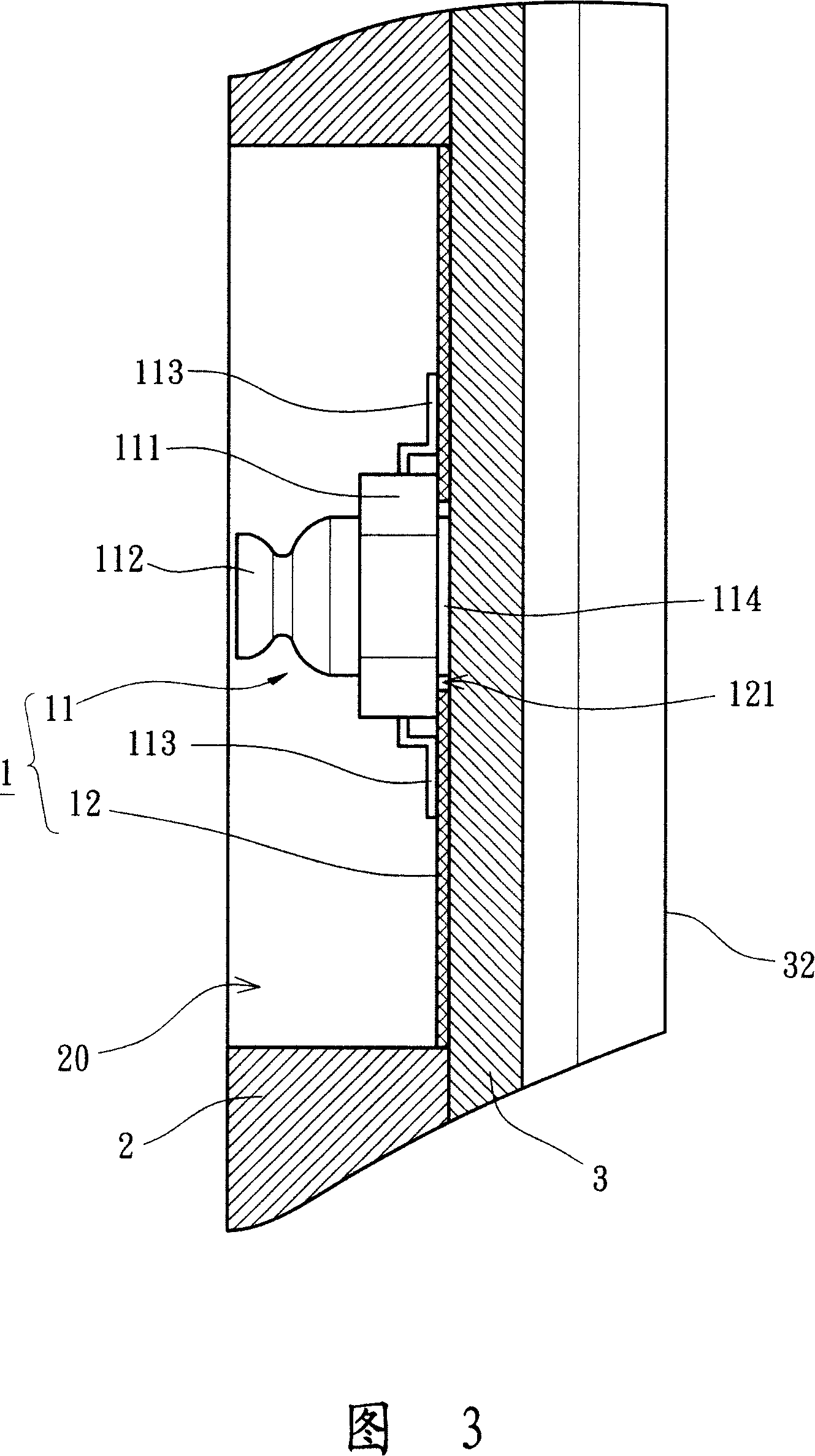

[0023] Please refer to Figures 2 and 4, in the first embodiment of the present invention, the backlight cooling device of the flat panel display is preferably combined on the back of a flat panel display (FPD), and the flat panel display a is preferably a liquid crystal display (liquid crystal display, LCD) or plasma display (plasma display panel, PDP), etc., in order to provide light for the backlight and perform heat dissipation at the same time.

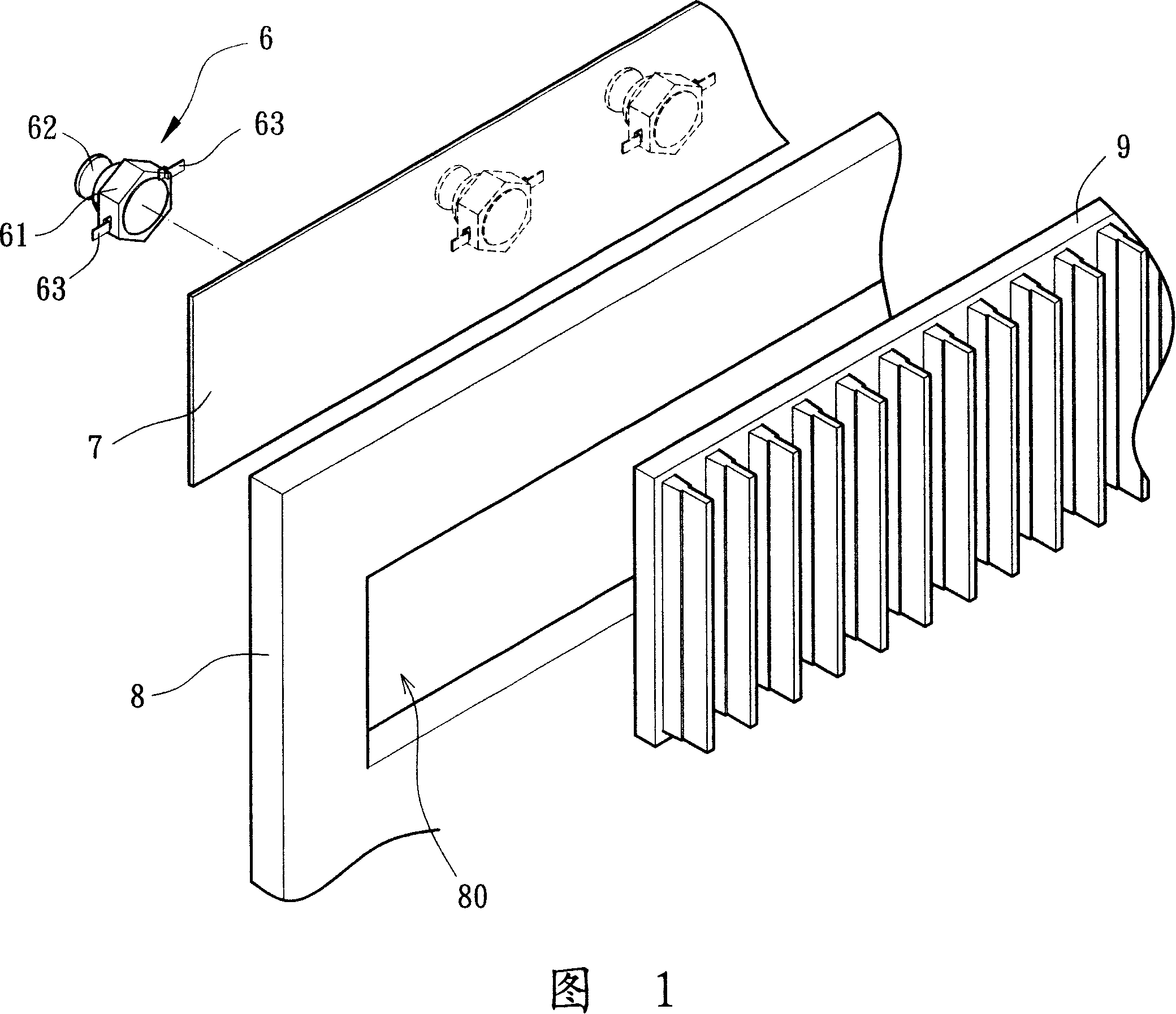

[0024] Please refer to FIGS. 2-3, in the first embodiment of the present invention, the backlight cooling device of the flat panel display includes at least one backlight module 1, a support frame 2 and at least one heat dissipation substrate 3, the backlig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com