Shock-absorbing blasting method used for bedding rock cutting excavation

A cutting and rock technology, which is applied in the field of shock-absorbing blasting for excavation of bedding rock cuttings, can solve problems such as increased engineering costs, reduced anti-sliding force of slopes, and influence on smooth construction, so as to ensure construction safety, The effect of maintaining self-stabilization ability and reducing reinforcement and maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

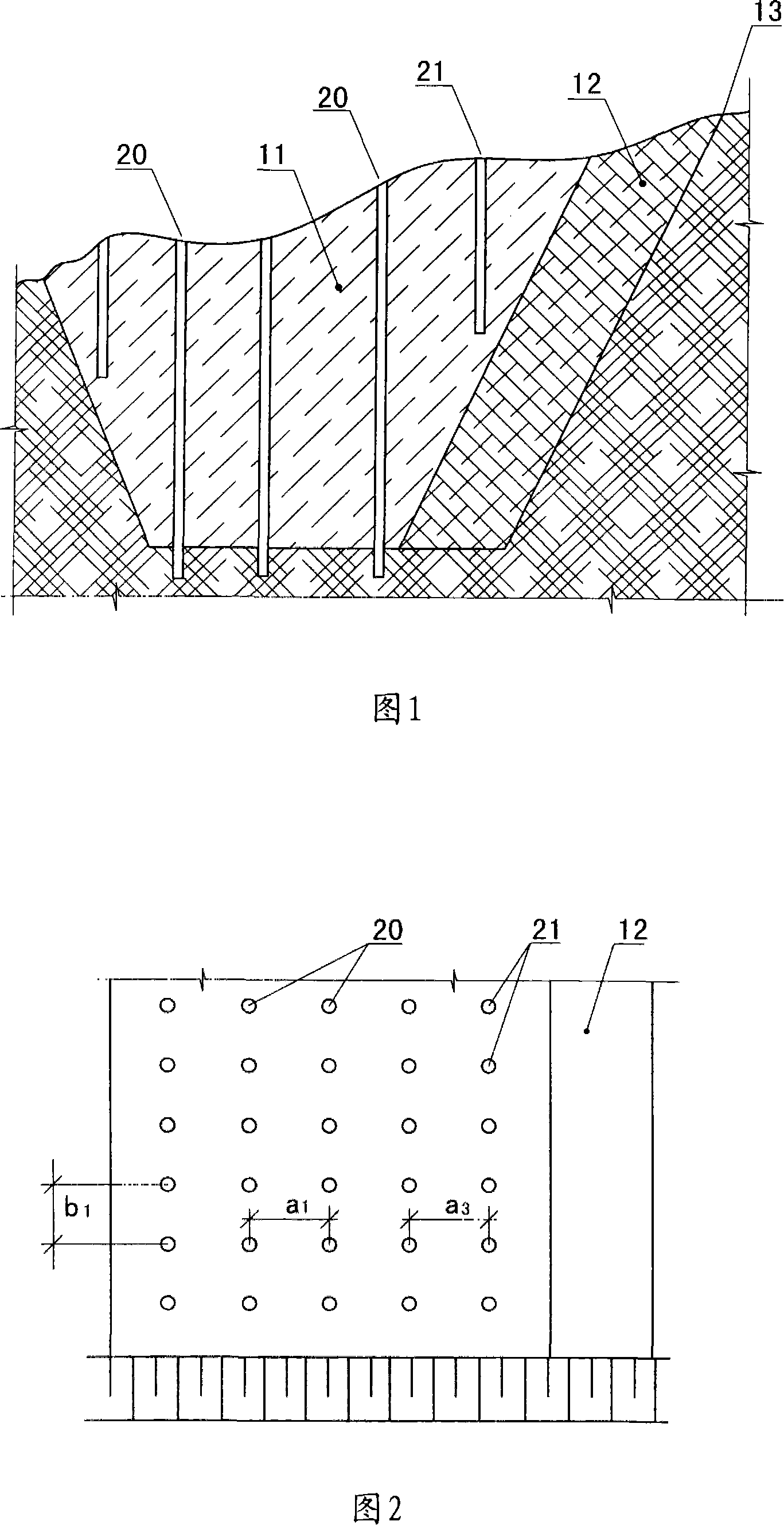

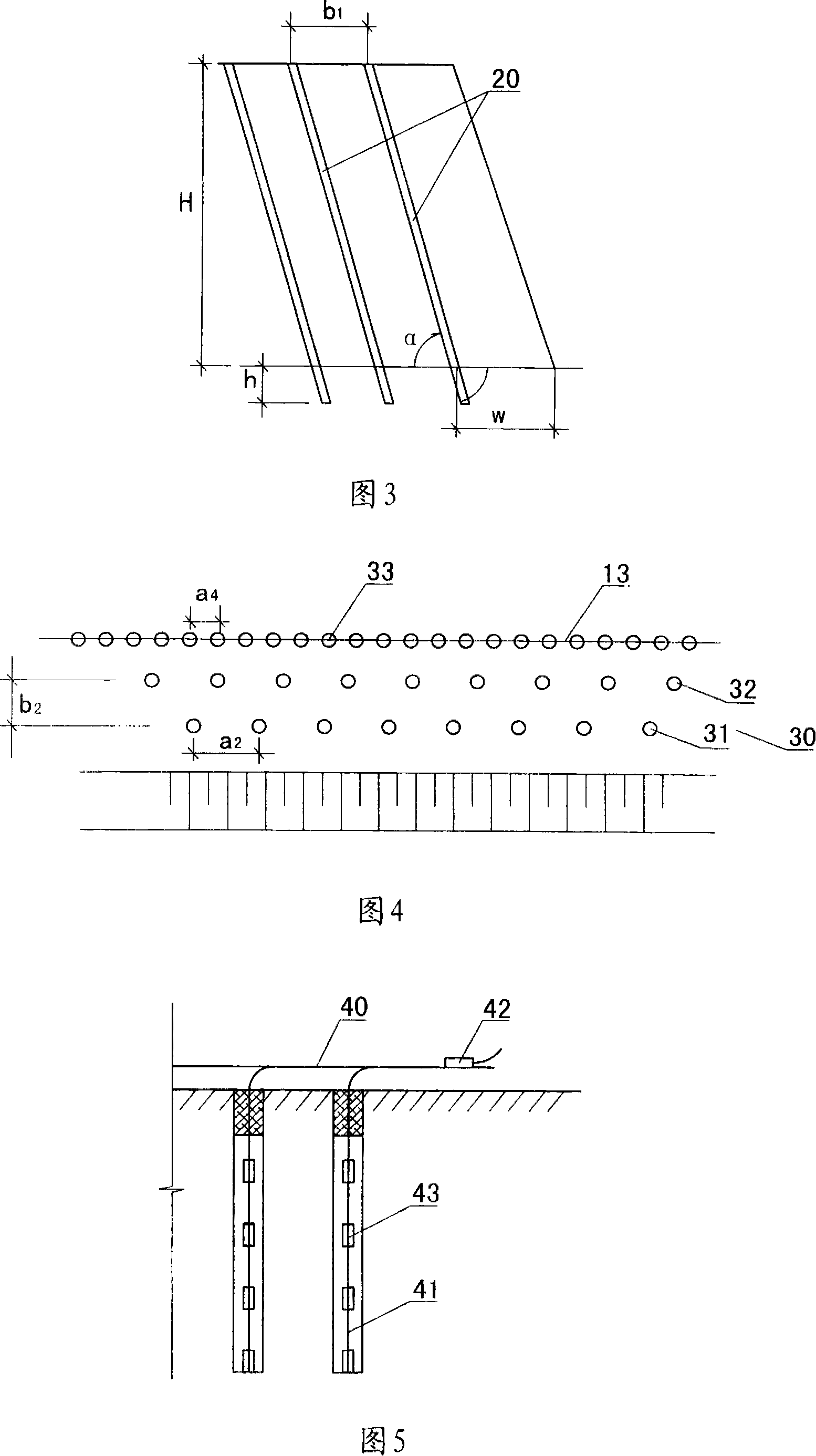

[0015] With reference to Fig. 1, the shock-absorbing blasting method that the present invention is used for the excavation of bedding rocky road cutting comprises the following steps: divide main excavation area 11 on cutting excavation section, main excavation area 11 and excavation boundary (13 ) is reserved between the protective layer 12; deep hole blasting is carried out on the main excavation area 11; When deep hole blasting is carried out in the main excavation area 11, the reserved protective layer 12 can play a role of shock isolation, which can effectively weaken the impact of blasting vibration on slope stability, thereby ensuring the smooth progress of construction, and is conducive to control and Reduce engineering costs.

[0016] The thickness of the protective layer 12 can be determined according to the range of rock mass spallation allo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com