Seamless split joint video frequency wall

A seamless splicing, video wall technology, applied in the direction of identification devices, optical fibers, instruments, etc., can solve problems such as not, achieve the effect of simple manufacturing, eliminate physical splicing gaps, and ensure continuity and integrity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

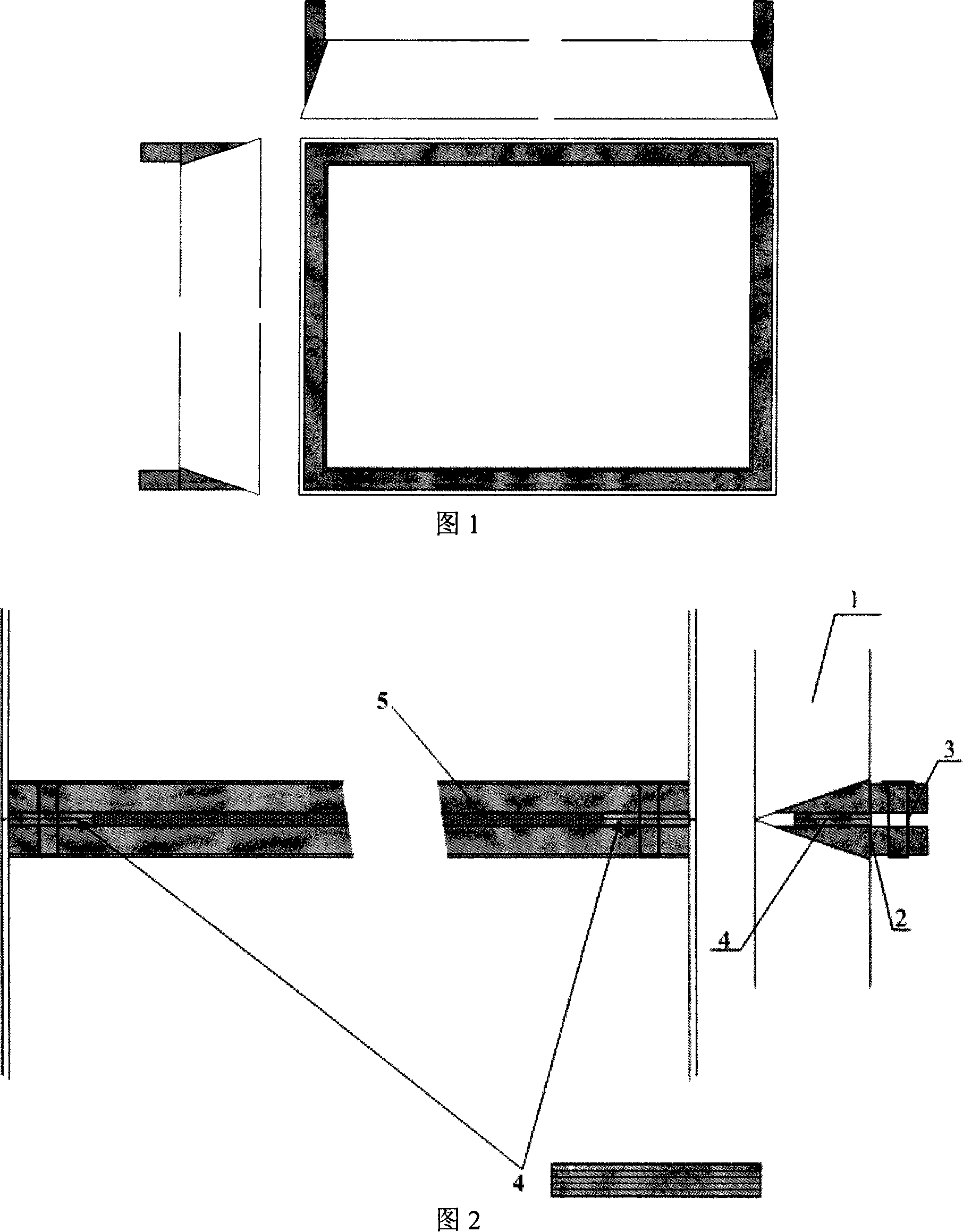

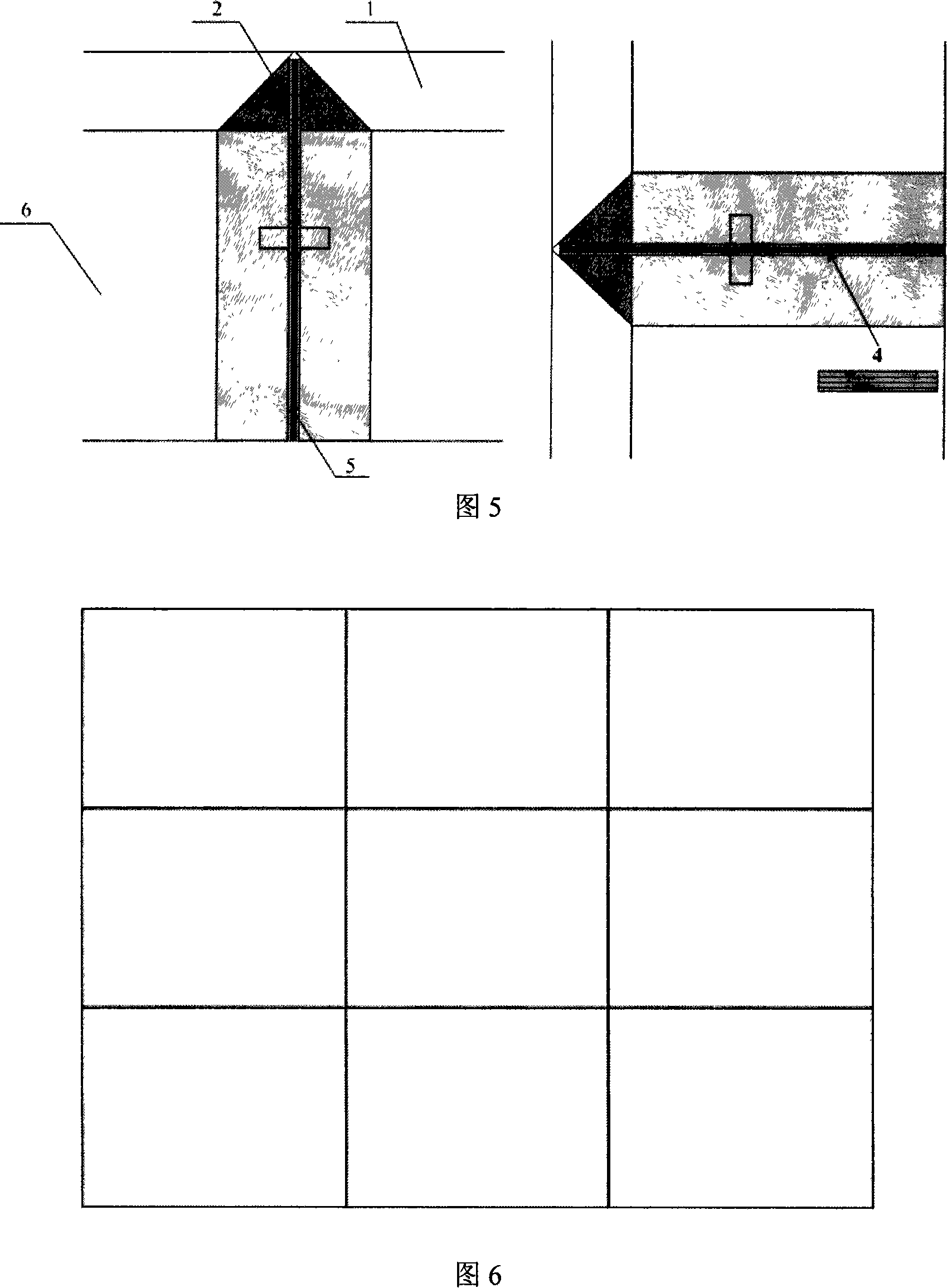

[0018] Figure 1: Customize the mold for the screen frame according to the structure, splice the mold into a frame according to the size of the screen, embed the screen in the frame, and embed all the trapezoidal bodies around the screen except 0.1-5mm behind the imaging surface of the screen in the connecting fixed frame Inside, the exposed part of the screen is 0.1-5 mm, depending on the size of the screen, the smaller the screen, the smaller the exposed part, and the plane of the exposed part of the screen is slightly larger than the frame border by 0.05-2 mm for seamless splicing with the screen.

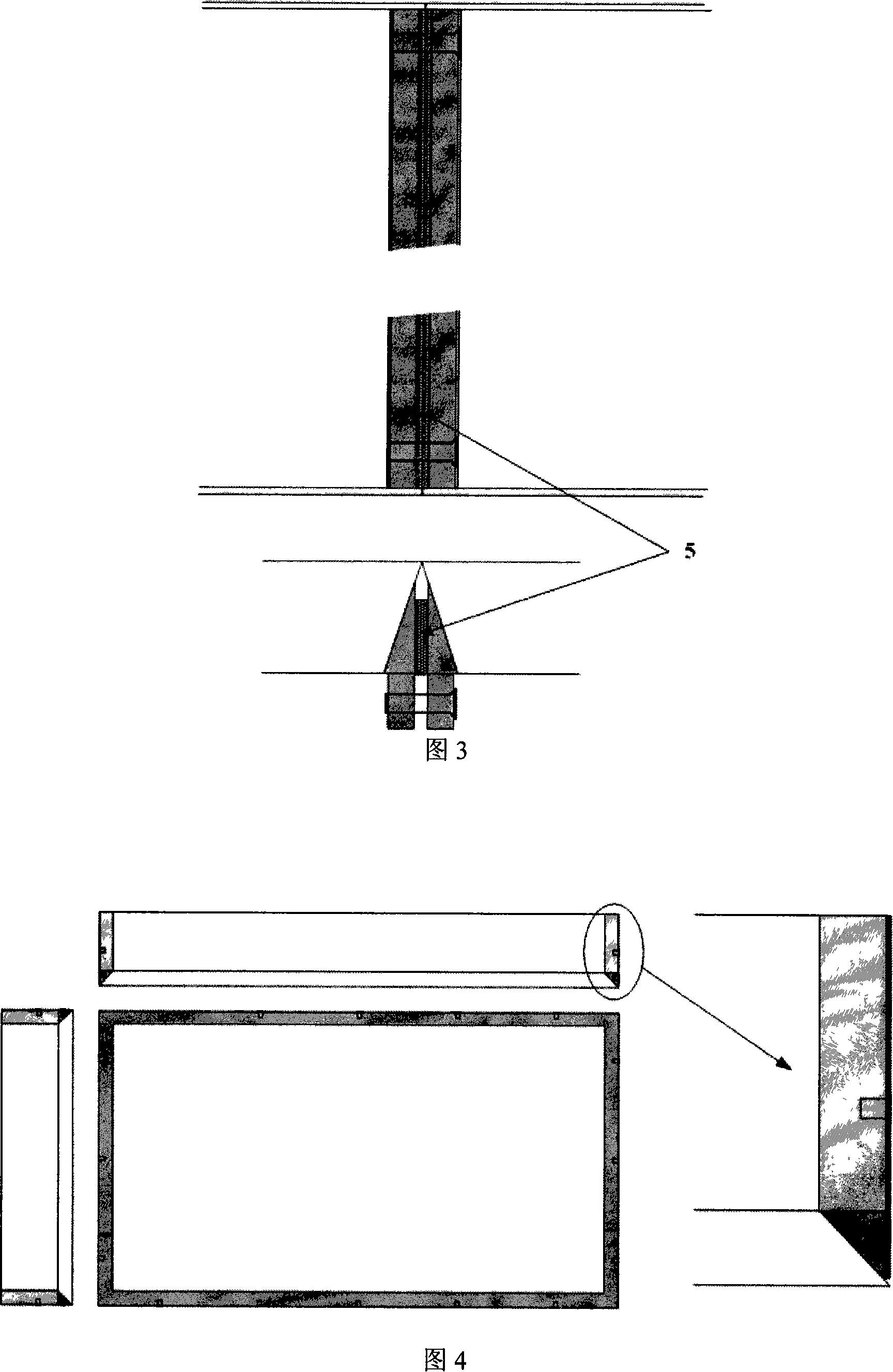

[0019] Figure 2, Figure 3: One is horizontal splicing and the other is vertical splicing, the specific implementation method is always. There are positioning screw holes on the rear frame of the screen frame, which are used for the positioning and fixed connection between the screens. The adjacent screen frames are connected by bolts. There are load-bearing gaskets between the fra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com