A preparation method of a three-dimensional fluffy porous scaffold

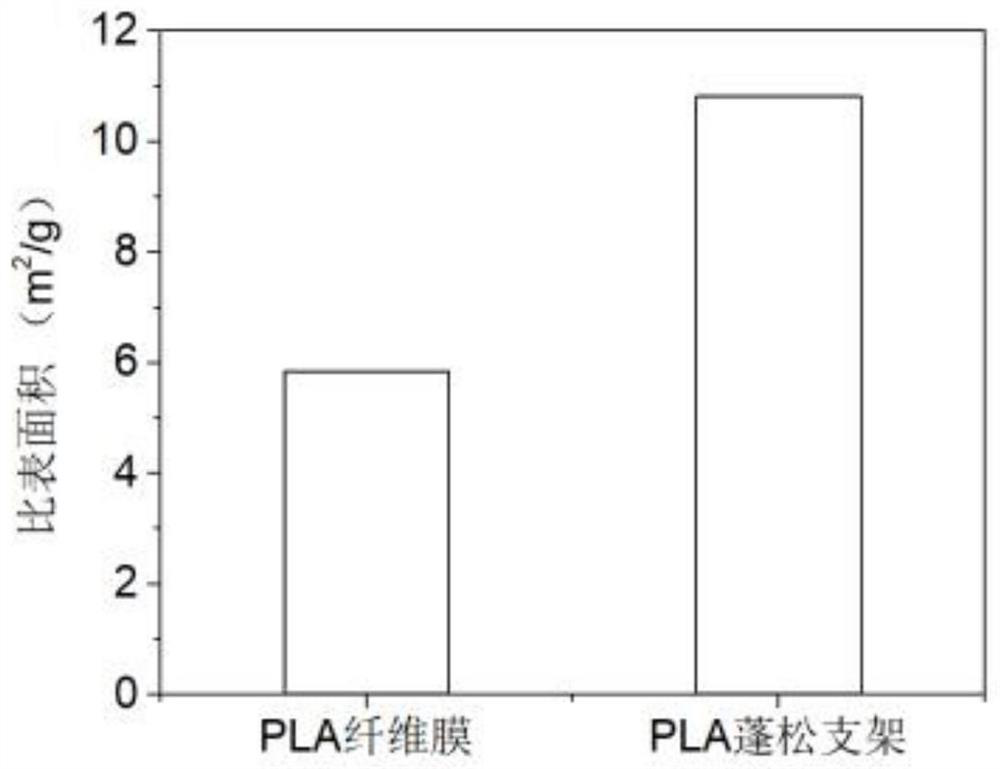

A porous scaffold and fluffy technology, which is applied in the field of preparation of three-dimensional fluffy porous scaffolds, can solve the problems of low porosity and poor connectivity of porous scaffolds, and achieve the effect of ensuring safety, non-toxicity, high porosity and high porosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

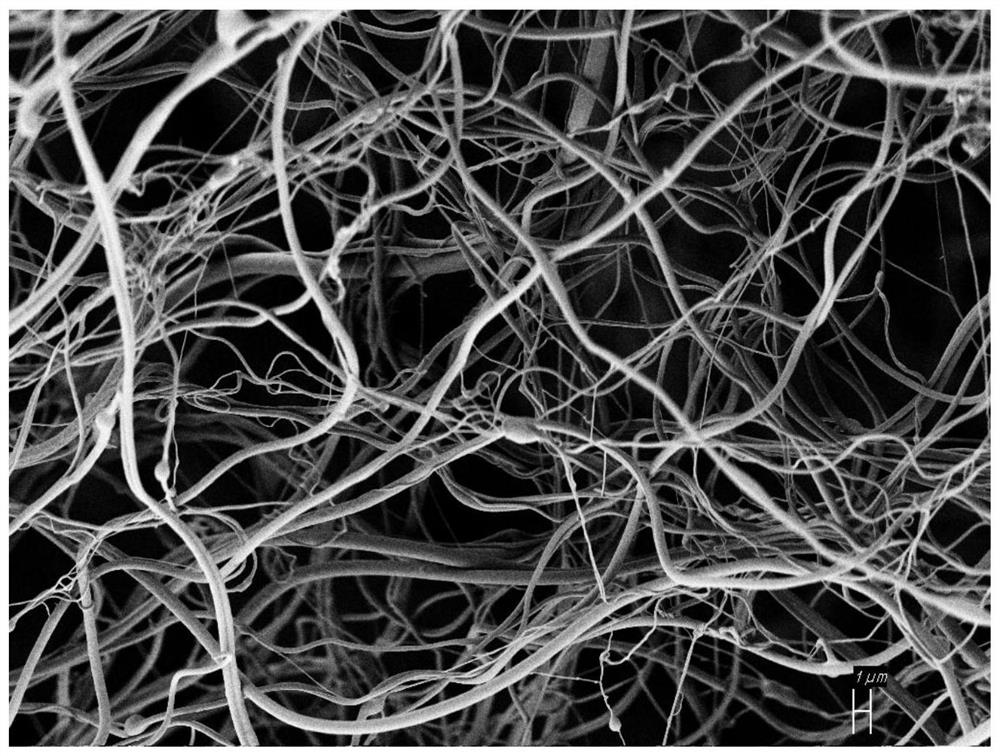

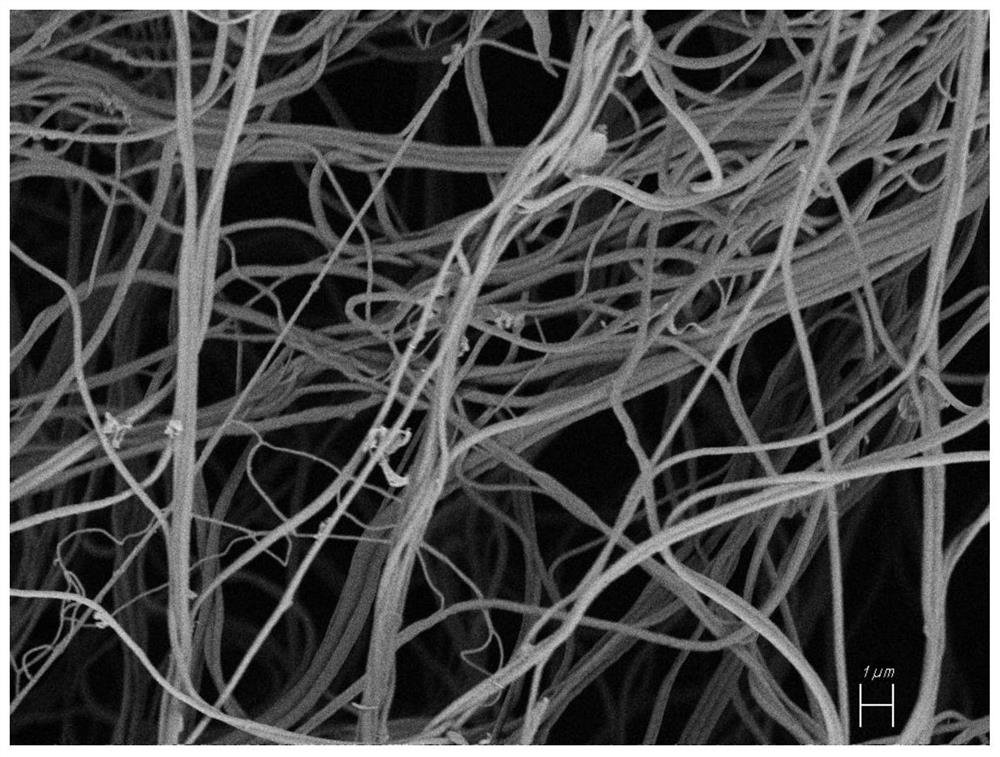

Image

Examples

Embodiment 1

[0035] S1. Polycaprolactone and 2,2,2-tetrafluoroethanol are dissolved to obtain a polymer solution with a concentration of 10wt.%;

[0036] S2. The polycaprolactone solution prepared in step S1 is subjected to electrospinning with a voltage of 18kV and a receiving distance of 15cm, and a polycaprolactone nanofiber is obtained by using alcohol with a volume concentration of 70% as the electrospinning receiving solution;

[0037] S3. place the polycaprolactone nanofibers prepared in step S2 in a pre-cooled alcohol / dry ice mixture with a mass ratio of 1:3, and let stand for 25min;

[0038] S4. Take out the polycaprolactone nanofibers processed in step S3 and place them in water at 25° C. for 5 minutes, and then take them out and quickly freeze them with liquid nitrogen for 15 minutes;

[0039] S5. freeze-dry the polycaprolactone nanofibers frozen in step S4 for 24 hours to obtain a polycaprolactone three-dimensional porous scaffold.

Embodiment 2

[0041] S1. Polycaprolactone and 2,2,2-tetrafluoroethanol are dissolved to obtain a polymer solution with a concentration of 8wt.%;

[0042] S2. carrying out the electrospinning of the polycaprolactone solution prepared in step S1 with a voltage of 15kV and a receiving distance of 10cm, and using alcohol with a volume concentration of 70% as the electrospinning receiving solution to obtain polycaprolactone nanofibers;

[0043] S3. place the polycaprolactone nanofibers prepared in step S2 in a pre-cooled alcohol / dry ice mixture with a mass ratio of 1:3, and let stand for 20min;

[0044] S4. Take out the polycaprolactone nanofibers treated in step S3 and place them in water at 20° C. for 7 minutes, then take them out and quickly freeze them with liquid nitrogen for 10 minutes;

[0045] S5. freeze-drying the polycaprolactone nanofibers frozen in step S4 for 36 hours to obtain a polycaprolactone three-dimensional porous scaffold.

Embodiment 3

[0047] S1. Polycaprolactone and 2,2,2-tetrafluoroethanol are dissolved to obtain a polymer solution with a concentration of 15wt.%;

[0048] S2. The polycaprolactone solution prepared in step S1 is subjected to electrospinning with a voltage of 20 kV and a receiving distance of 20 cm, and a polycaprolactone nanofiber is obtained by using alcohol with a volume concentration of 70% as the electrospinning receiving solution;

[0049] S3. Place the polycaprolactone nanofibers prepared in step S2 in a pre-cooled alcohol / dry ice mixture with a mass ratio of 1:5, and let stand for 30min;

[0050] S4. Take out the polycaprolactone nanofibers processed in step S3 and place them in water at 30°C for 3 minutes, then take them out and freeze them quickly with liquid nitrogen for 20 minutes;

[0051] S5. freeze-dry the polycaprolactone nanofibers frozen in step S4 for 12 hours to obtain a polycaprolactone three-dimensional porous scaffold.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com