Liquid crystal composition and liquid crystal display device

A technology of liquid crystal composition and compound, applied in liquid crystal materials, optics, instruments, etc., can solve the problems of no high transparent point and high viscosity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0288] The following compositions were prepared, and each characteristic value was measured according to the above method.

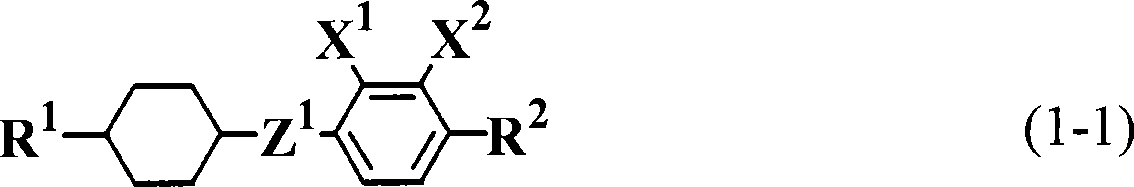

[0289] 3-HB(2F,3Cl)-02 (1-1-1) 14%

[0290] 5-HB(2F,3Cl)-02 (1-1-1) 14%

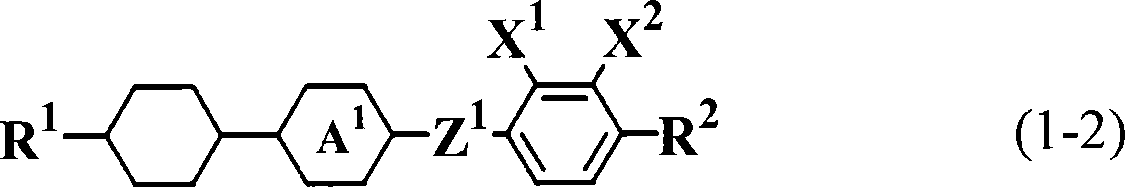

[0291] 3-HHB(2F,3Cl)-02 (1-2-1) 8%

[0292] 5-HHB(2F,3Cl)-02 (1-2-1) 8%

[0293] 3-HH2B(2F,3Cl)-02 (1-2-2) 9%

[0294] 5-HH2B(2F,3Cl)-02 (1-2-2) 9%

[0295] 2-HH-5 (2-1-1) 11%

[0296] 3-HH-4 (2-1-1) 11%

[0297] 3-HB-02 (2-1-2) 8%

[0298] 5-HB-02 (2-1-2) 8%

[0299] NI=69.3°C; Tc≤-20°C; Δn=0.073; Δε=-2.7;

[0300] VHR-1 = 99.4%.

[0301] Compared with Comparative Example 1, the lower limit temperature of the composition of Example 1 is as low as ≤-20° C., and Δn is also smaller. This in turn has a greater voltage retention rate.

Embodiment 2

[0303] The following compositions were prepared, and each characteristic value was measured according to the above method.

[0304] 3-HB(2F,3Cl)-02 (1-1-1) 15%

[0305] 5-HB(2F,3Cl)-02 (1-1-1) 15%

[0306] 3-HHB(2F,3Cl)-02 (1-2-1) 9%

[0307] 5-HHB(2F,3Cl)-02 (1-2-1) 9%

[0308] 3-HBB(2F,3Cl)-02 (1-2-7) 9%

[0309] 5-HBB(2F,3Cl)-02 (1-2-7) 9%

[0310] 2-HH-5 (2-1-1) 11%

[0311] 3-HH-4 (2-1-1) 12%

[0312] 3-HB-02 (2-1-2) 11%

[0313] NI=69.0°C; Tc≤-20°C; Δn=0.086; Δε=-3.0;

[0314] VHR-1 = 99.2%.

[0315] Compared with Comparative Example 1, the lower limit temperature of the composition of Example 2 is as low as ≤-20°C. This in turn has a greater voltage retention rate.

Embodiment 3

[0317] The following compositions were prepared, and each characteristic value was measured according to the above method.

[0318] 3-HB(2Cl,3F)-02 (1-1-4) 5%

[0319] 5-HB(2Cl,3F)-02 (1-1-4) 5%

[0320] 3-H2B(2Cl,3F)-02 (1-1-5) 15%

[0321] 5-H2B(2Cl,3F)-02 (1-1-5) 15%

[0322] 3-HHB(2Cl,3F)-02 (1-2-4) 8%

[0323] 5-HHB(2Cl,3F)-02 (1-2-4) 8%

[0324] 3-HH2B(2Cl,3F)-02 (1-2-5) 12%

[0325] 5-HH2B(2Cl,3F)-02 (1-2-5) 12%

[0326] 5-HH-V (2-1-1) 17%

[0327] V-HHB-1 (2-2-1) 3%

[0328] NI=70.0°C; Tc≤-20°C; Δn=0.075; Δε=-3.4;

[0329] VHR-1 = 99.2%.

[0330] Compared with Comparative Example 1, the lower limit temperature of the composition of Example 3 is as low as ≤ -20°C. This in turn has a greater voltage retention rate.

PUM

| Property | Measurement | Unit |

|---|---|---|

| coating thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com